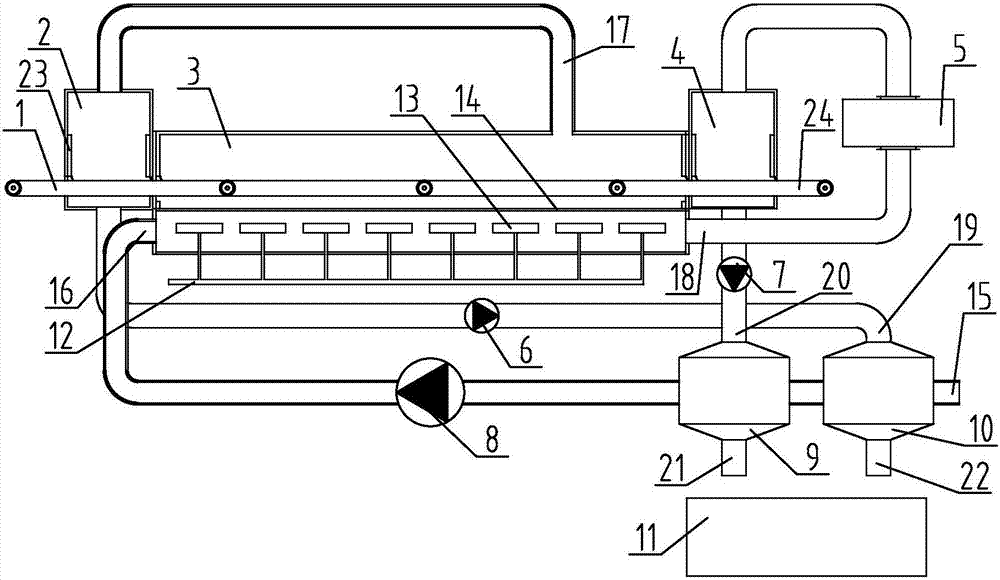

Four-section thermal cycling kelp drying device

A drying device and thermal cycle technology, which is applied in the fields of application, food processing, food science, etc., can solve the problems of undersaturation, energy waste, etc., and achieve the effects of improving direct action, reducing gas consumption, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The first-stage return air drying box 2 is connected in series with the front end of the heat radiation drying box 3, and the end of the heat radiation drying box 3 is connected in series with the gas hot air drying box 4, and all the inlets and outlets of the drying boxes are equipped with material feeding one-way doors 23. The kelp particles need to be dried for a period through the kelp preheating tank 11 . The kelp particles are sent to the primary return air drying box 2 through the entrance 1 of the kelp conveyor chain for secondary drying. Through the kelp conveyor chain, the kelp particles dried in the second stage are sent to the thermal radiation drying box 3 for three-stage drying, and the kelp particles after the three-stage drying are sent into the gas hot air drying box 4 through the kelp conveyor chain for drying. Four stages of drying, the dried kelp particles are sent out through the kelp conveyor chain outlet 24.

[0019] The fan 1 transports the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com