Tubular electrode abrasive particle assisting multi-bath electrolytic cutting machining device and method

A cutting method and a technology of cutting tools, which are applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as ignition short circuit, poor processing surface quality, electrolyte flow disorder, etc., and achieve the effect of uniform and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

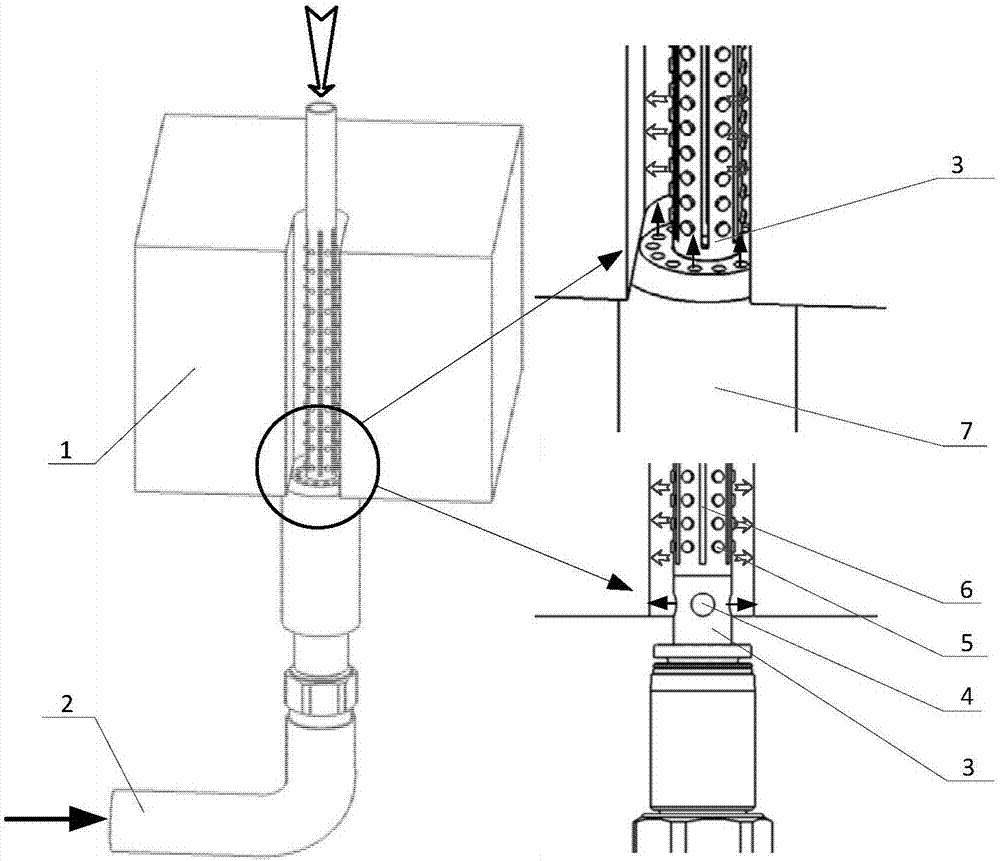

[0025] figure 1 In the schematic diagram of tube electrode abrasive particle-assisted multi-groove electrolytic cutting shown in the figure, firstly adjust the distance between the tube electrode 3 sidewall liquid spray seam and the workpiece 1; then, turn on the constant pressure pump 15 to adjust the fluid supply pressure parameters; finally, Set the processing curve and processing parameters in the control system, turn on the power to start processing, and after the tool has completely cut into the workpiece, turn on the blower and adjust the blowing pressure parameters of the blower to ensure that the electrolyte in the processing area can flow out smoothly and stably.

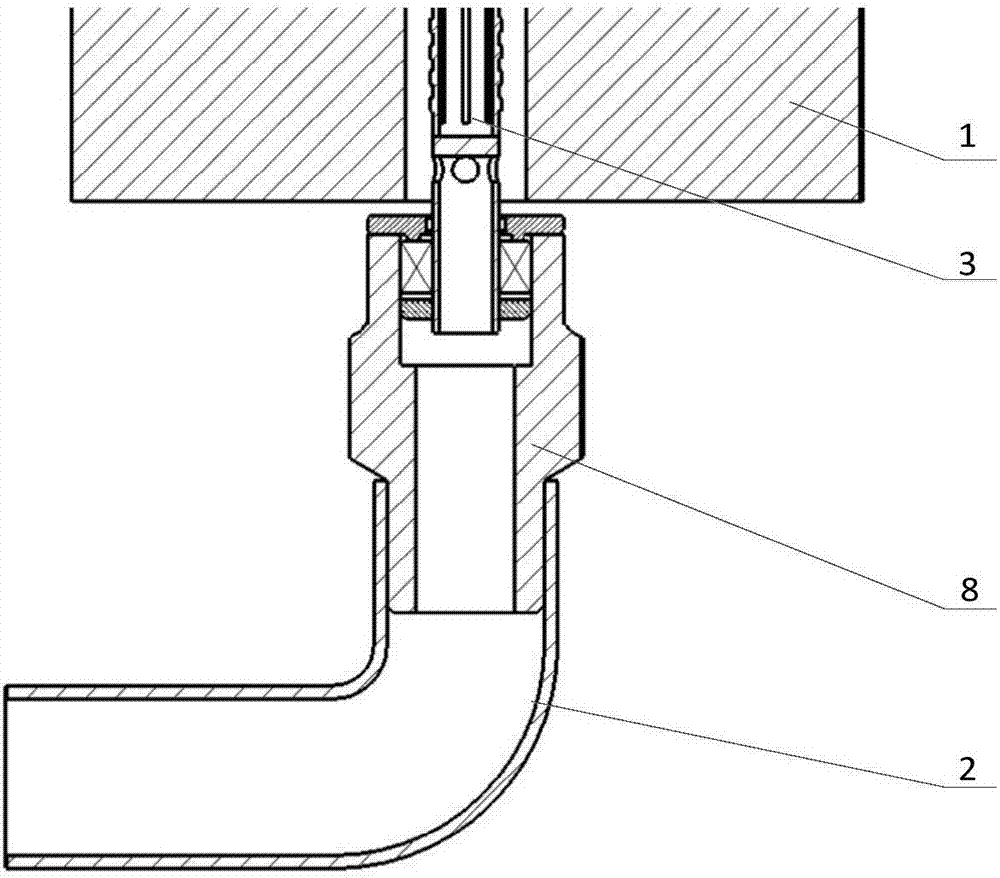

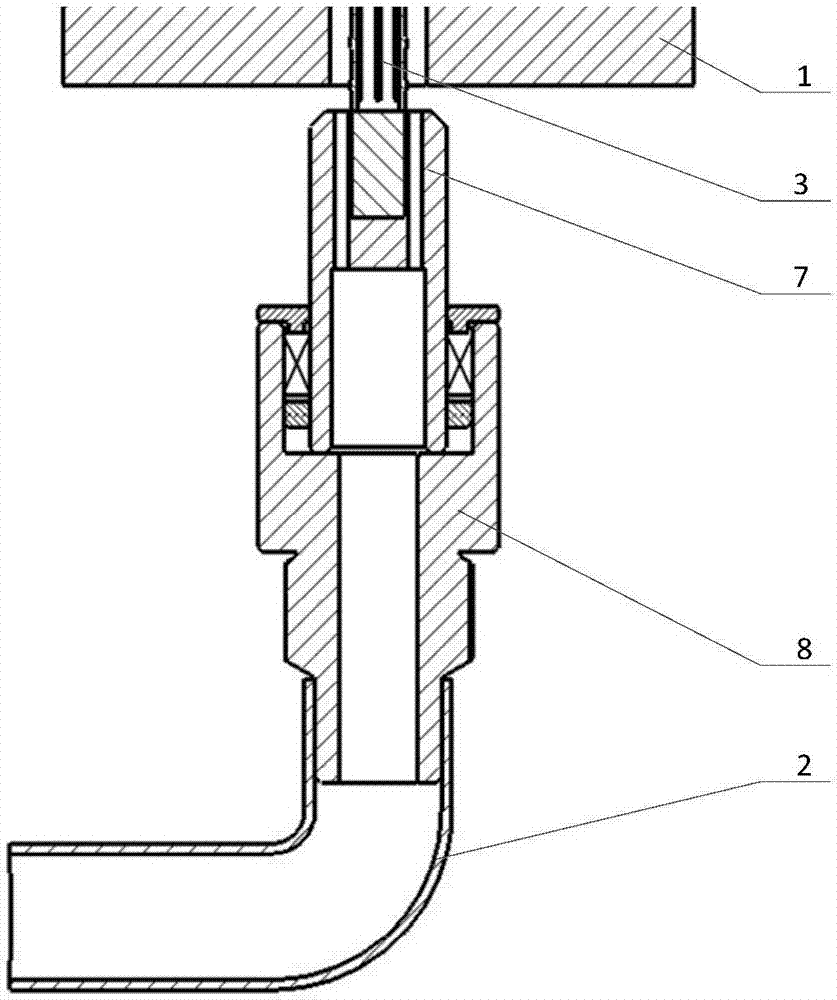

[0026] figure 2 In the cross-sectional view of the structure of the radial blowing mode of the tube electrode abrasive particle auxiliary device shown, the gas is supplied by the air pump, enters the rotary adapter 8 from the intake pipe 2, and finally is sprayed out through the blow hole at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com