Machining tool and process for thin-wall long barrel part with window

A part processing and window technology, which is applied in the field of processing tooling and technology of thin-walled long-tube parts with windows, can solve the problems of unsatisfactory roughness, easy deformation of clamping, unstable linear dimension tolerance, etc., to solve the problem of part deformation and linearity Unstable dimensional tolerance, enhanced positioning accuracy, and the effect of avoiding part offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

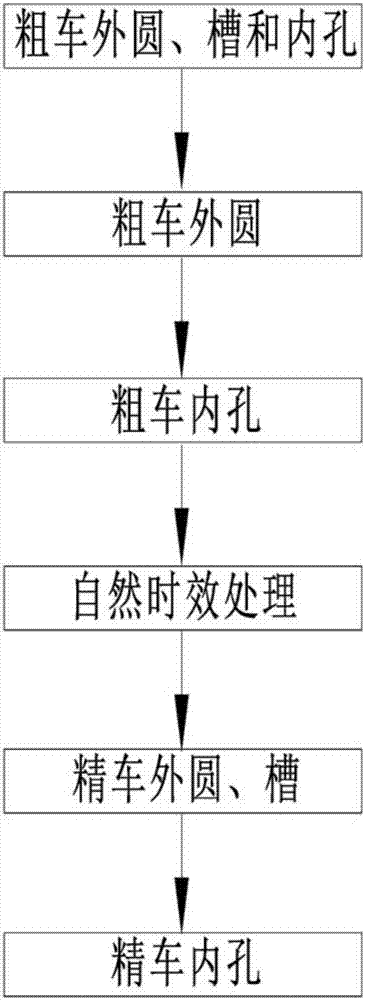

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

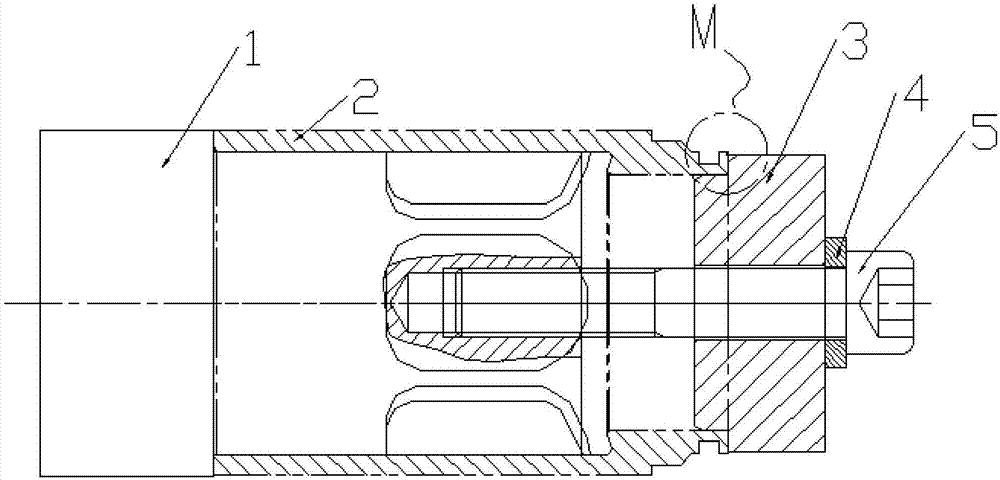

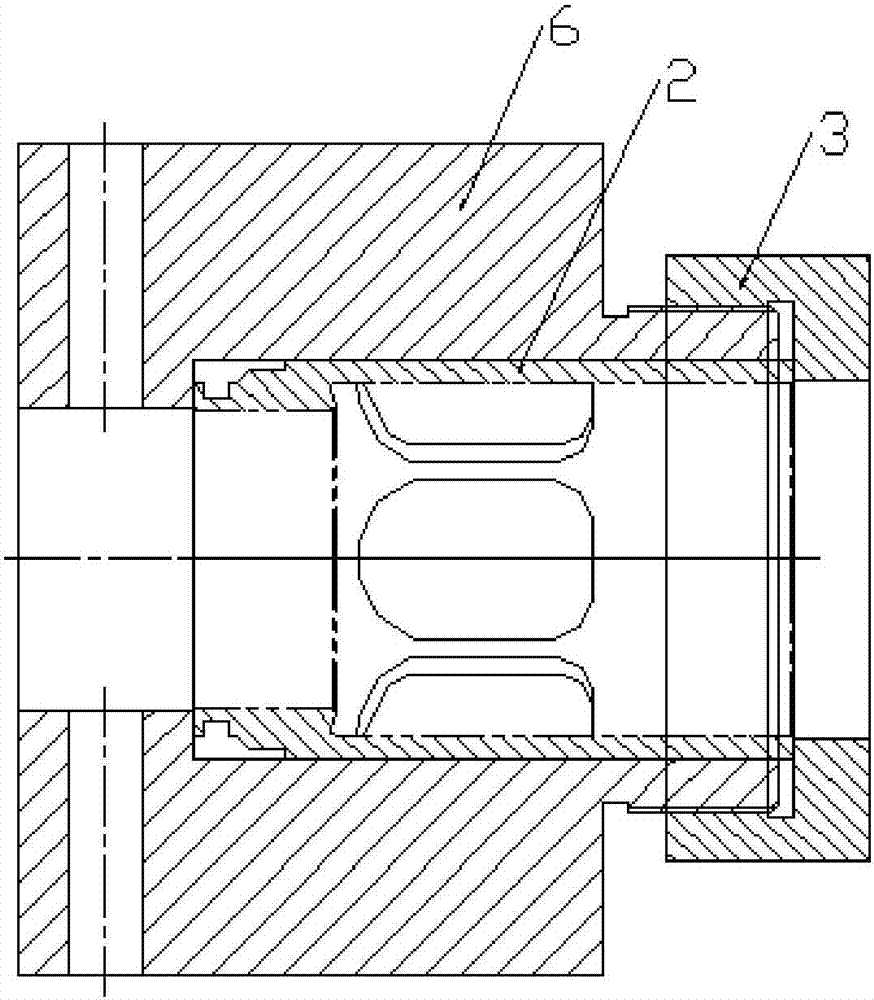

[0027] A processing tool for thin-walled long cylinder parts with windows, comprising a positioning core 1, a pressure plate 3, a gasket 4, a bolt 5, and a positioning barrel 6; the positioning core 1 is arranged on one side of the pressure plate 3, and the gasket 4 It is arranged on the other side of the pressing plate 3 , and the bolt 5 is arranged on the side of the gasket 4 away from the pressing plate 3 ; wherein, the positioning bucket 6 is arranged on the same side of the positioning core 1 .

[0028] The diameter of the positioning barrel 6 is larger than the diameter of the positioning core 1 , and the diameter of the bolt 5 is slightly smaller than the diameter of the gasket 4 .

[0029] Specifically, when finishing the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com