Movable building block brick stacking machine

A brick palletizer, mobile technology, applied in the field of palletizers, can solve the problems of time-consuming and laborious manual palletizing, artificial danger, etc., and achieve the effect of reducing workload and avoiding palletizing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

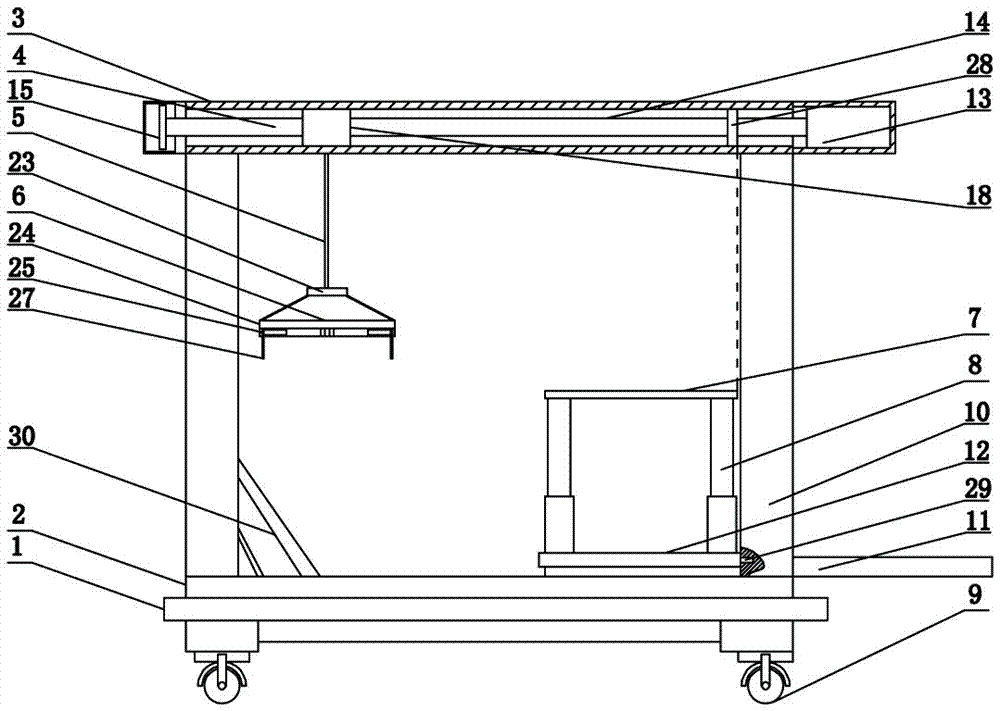

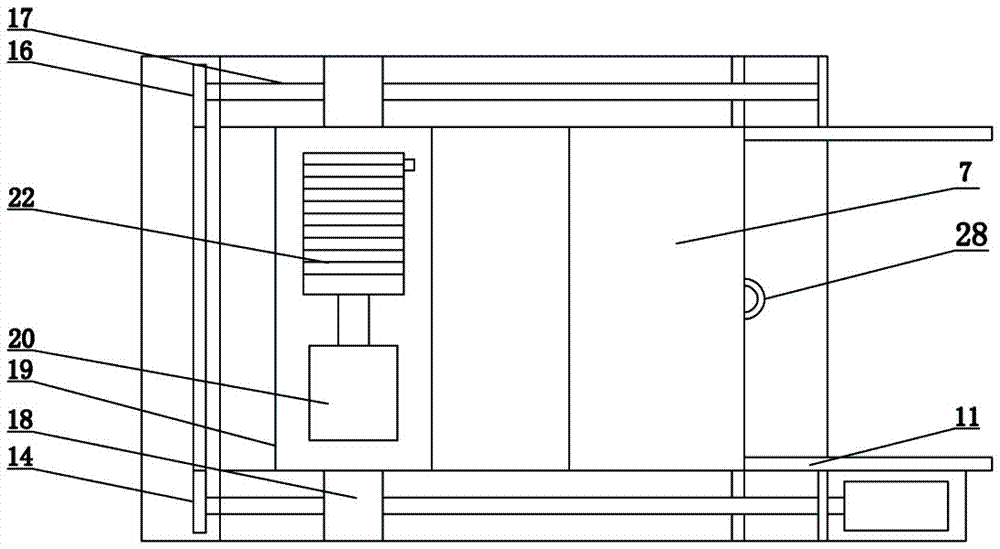

[0022] to combine Figure 1 to Figure 3 As shown, a mobile block brick palletizer disclosed in this embodiment includes a mobile frame 1, a mounting frame 2, a mounting beam 3, a lateral moving device 4, a palletizing and clamping lifting device 5, and a palletizing and clamping device 6. Palletizing platform 7, Palletizing platform lifting device 8;

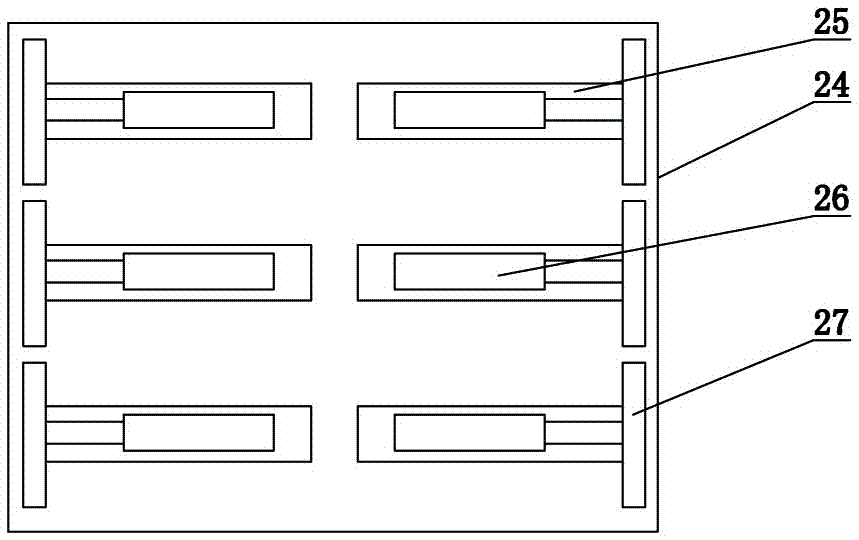

[0023] There are two groups of installation chutes on the installation frame 2, the mobile frame 1 is arranged in the installation chute, the mobile universal wheels 9 are arranged on the mobile frame 1, and four groups of Install uprights 10, each two groups of said installation uprights 10 are fixedly connected with a set of said installation beams 3, said installation beams 3 are provided with a lateral movement device 4, said lateral movement device 4 is provided with said stacking clips Lifting device 5, the palletizing clamping lifting device 5 is connected with the palletizing clamping device 6, two groups of moving ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com