Cement grinding aid and production method thereof

A cement grinding aid and acid solvent technology, applied in the field of cement adjuvant preparations, can solve the problems of poor stability, unsatisfactory cement setting time and compressive strength, etc., and achieve excellent flow performance, increase production per hour, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Make cement grinding aid based on following proportioning by weight:

[0030] First put 30 parts of polyols, 5 parts of calcium lignosulfonate and 1 part of 50% hydrochloric acid solution with a pH of 2 to 3 into the reactor for mixing, then add 5 parts of alkaline lignin into the reactor, Adjust the pH value of the mixture to 6, then add 5 parts of triethanolamine and 5 parts of diethanol monoisopropanolamine to the reaction kettle, and let it stand for 2 hours, finally import the mixture after standing still from the reaction kettle into the stirring tank, add 60 parts of water and 10 parts of molasses were stirred and stirred for 1 hour to obtain a cement grinding aid.

Embodiment 2

[0032] Make cement grinding aid based on following proportioning by weight:

[0033] First put 60 parts of polyols, 10 parts of calcium lignosulfonate and 4 parts of 50% sulfuric acid solution with a pH of 2 to 3 into the reactor for mixing, then add 10 parts of alkaline lignin into the reactor, Adjust the pH value of the mixture to 8, then add 10 parts of triethanolamine and 10 parts of diethanol monoisopropanolamine to the reactor, and let it stand for 3 hours, and finally import the mixture after standing still from the reactor to the stirring tank, add 80 parts of water and 20 parts of molasses were stirred together, and after 1.5 hours of stirring, a cement grinding aid was prepared.

Embodiment 3

[0035] Make cement grinding aid based on following proportioning by weight:

[0036] First put 45 parts of polyols, 7 parts of calcium lignosulfonate and 2.5 parts of 50% hydrochloric acid solution with a pH of 2 to 3 into the reactor for mixing, then add 8 parts of alkaline lignin into the reactor, Adjust the pH value of the mixture to 7, then add 7 parts of triethanolamine and 8 parts of diethanol monoisopropanolamine in the reactor, and let stand for 2.5h, finally import the mixture after standing from the reactor to the stirring tank, 70 parts of water and 15 parts of molasses were added and stirred, and the cement grinding aid was obtained after stirring for 1 hour.

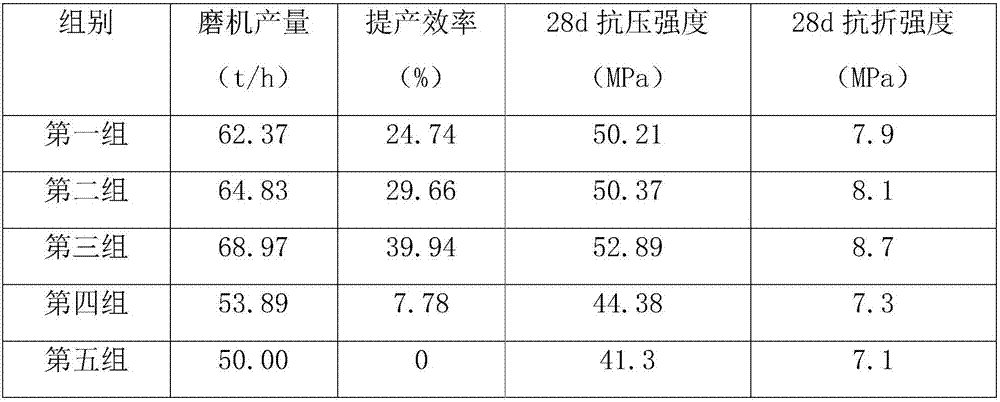

[0037] The cement grinding aids prepared by equal weight embodiment 1, embodiment 2 and embodiment 3 are marked as the first group, the second group and the third group respectively, and the existing commercially available grinding aids of equal weight are marked as The fourth group, its formula is calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com