Heat radiating paint for LED automobile lamp and application of heat radiating paint

A technology for LED car lights and heat-dissipating coatings, applied in anti-corrosion coatings, coatings, motor vehicles, etc., can solve the problems of poor heat dissipation, low product power, short life, etc., to reduce the cost of lighting systems and enhance anti-oxidation. The effect of increased performance and contact area

Inactive Publication Date: 2018-05-08

刘大国

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, LED automotive lighting is widely used and has promising prospects, but the existing products have low power, low luminous efficiency, and short life.

The reason is that the heat dissipation problem is not solved well, which hinders the widespread application of LED lighting in the automotive field.

Existing products mainly use 6063 aluminum profiles and micro-fans to force heat dissipation, but vibration, noise and electromagnetic interference are generated, which seriously affect the on-board computer and electronic control system, and the shortcomings of the fan itself, such as power consumption and short life, reduce the efficiency of the lighting. Reliability brings security risks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] 30% of boron nitride with a particle size of 50-60nm, 10% of titanium oxide with a particle size of 40-50nm, and 60% of thinner.

Embodiment 2

[0034] Boron nitride with a particle size of 60-70nm is 35%, titanium oxide with a particle size of 50-60nm is 10%, and thinner is 55%.

Embodiment 3

[0036] 40% of boron nitride with a particle size of 70-80nm, 3% of titanium oxide with a particle size of 60-70nm, and 57% of thinner.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

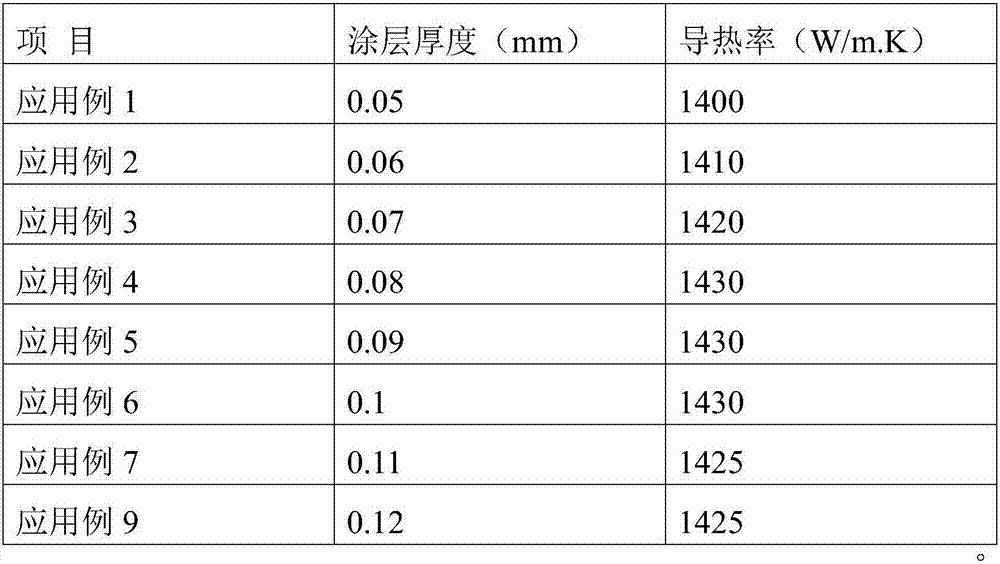

The invention discloses heat radiating paint for an LED automobile lamp and application of the heat radiating paint. The paint consists of 30-40wt% of small nanoscale boron nitride, 3-10wt% of nanoscale titanium oxide and 50-60wt% of thinner. During preparation, the thinner and boron nitride are uniformly mixed, and then, titanium oxide is added into the mixture and the obtained mixture is uniformly stirred. During application, the heat radiating paint coats the surface of a heat radiating body and is aired to be dry, roasted and cured to form a heat radiating coating. The heat conductivity ofthe surface of the heat radiating body coated with the heat radiating coating is larger than or equal to 1400W / (m*K), the heat radiating effect is remarkably improved, the oxidation resistance is improved, the cost of a lamp system is reduced, and the application range of an LED lamp in the field of automobiles is widened.

Description

【Technical field】 [0001] The invention relates to a heat-dissipating paint for LED car lights and an application thereof, belonging to the technical field of LED lighting materials. 【Background technique】 [0002] At present, LED automotive lighting is widely used and has promising prospects, but the existing products have low power, low luminous efficiency, and short life. The reason is mainly that the heat dissipation problem is not solved well, which hinders the widespread application of LED lighting in the automotive field. Existing products mainly use 6063 aluminum profiles and micro-fans to force heat dissipation, but vibration, noise and electromagnetic interference are generated, which seriously affect the on-board computer and electronic control system, and the shortcomings of the fan itself, such as power consumption and short life, reduce the efficiency of the lighting. Reliability brings security risks. 【Content of invention】 [0003] The object of the presen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D1/00C09D5/08F21V29/85F21W107/10F21Y115/10

CPCC09D1/00C09D5/08F21V29/85F21Y2115/10

Inventor 刘大国蔡祥发

Owner 刘大国

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com