Lithium Occlusion/Release Material, Electrode, Lithium Ion Secondary Battery, And Method For Manufacturing Lithium Occlusion/Release Material

A technology for releasing materials and manufacturing methods, which is applied in secondary batteries, nanotechnology for materials and surface science, battery electrodes, etc. problem, to achieve the effect of excellent charge/discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

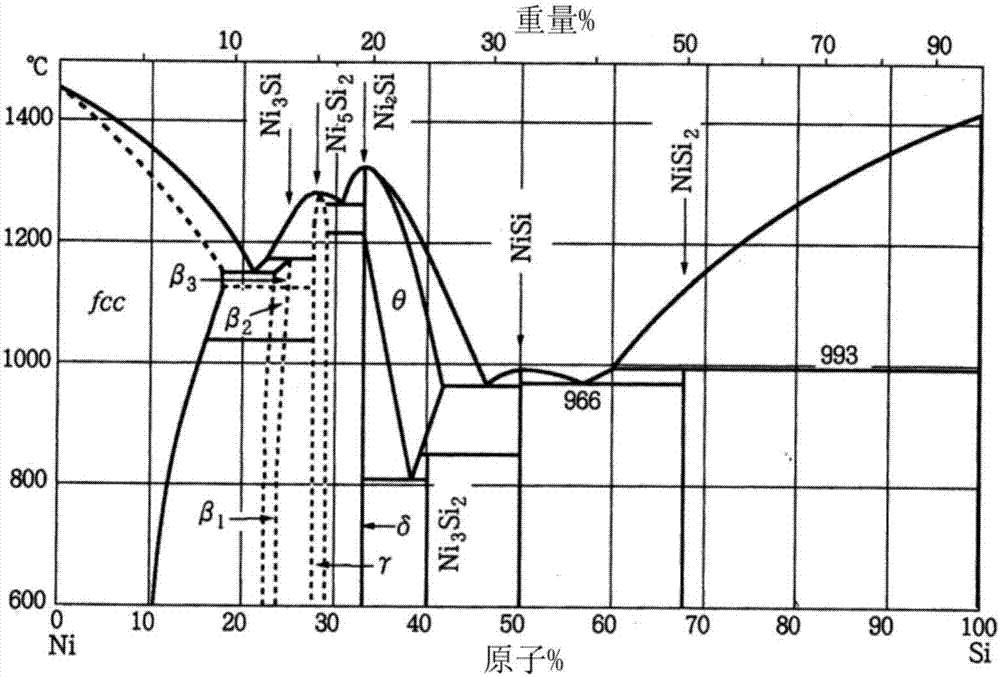

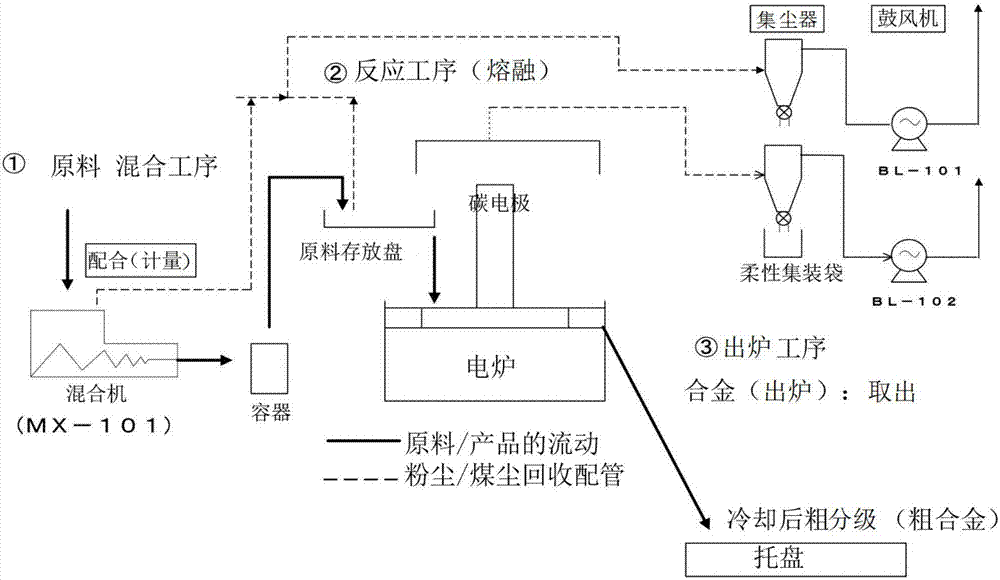

[0125] With respect to 100 kg of new nickel as a nickel source as a raw material, 306.6 kg of silica as a silicon source and 184.0 kg of charcoal as a carbon source are used. figure 2The method described in the production flow chart shown produces a lithium occlusion-release material. The composition of the molten material was managed so that the atomic ratio of Fe to Ni in the lithium storage-release material (Fe / Ni ratio) was 0.063 or less. In other examples and comparative examples, the management of the Fe / Ni ratio of the lithium occlusion-release material was also made the same. Cooling of the molten mass was performed by cooling from the molten state to 50° C. over 3 hours. The average cooling rate in this case was 0.1°C / sec. Thus, a lithium storage-release material having an atomic ratio of silicon to nickel (Si / Ni ratio) of 3.0 was obtained in a yield of 99%.

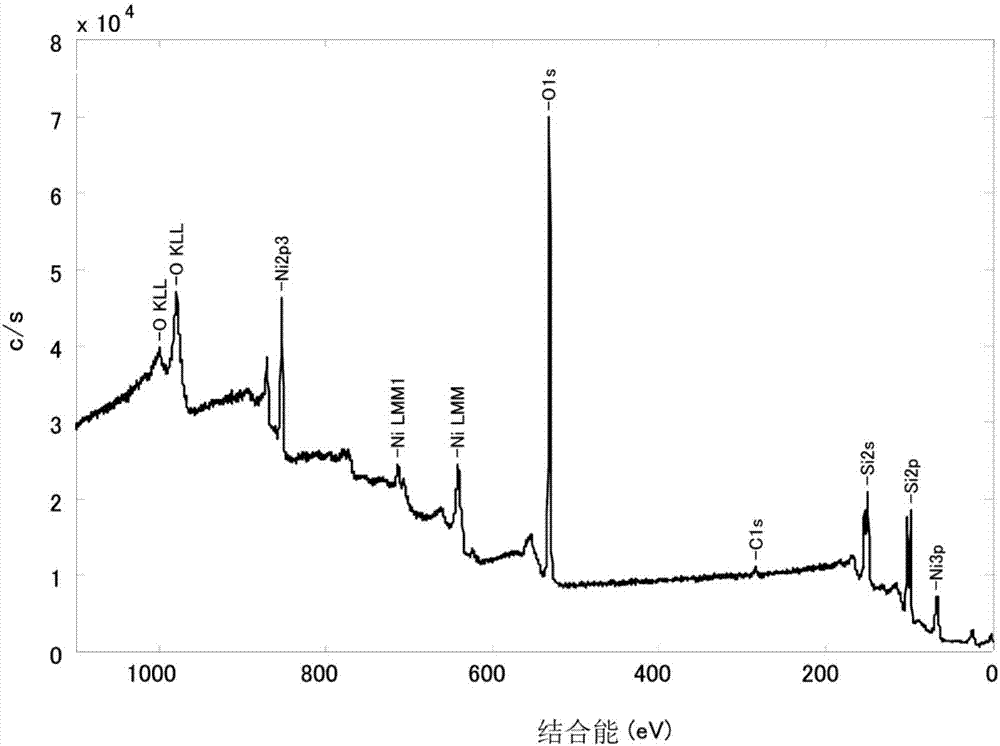

[0126] (Measurement example 1) X-ray photoelectron spectrum

[0127] The lithium occlusion-release mater...

Embodiment 2

[0150] With respect to 100 kg of new nickel as a nickel source as a raw material, 255.5 kg of silica as a silicon source and 153.2 kg of charcoal as a carbon source are used. figure 2 The method described in the production flow chart shown produces a lithium occlusion-release material. Cooling of the molten mass was performed by cooling from the molten state to 50° C. over 3 hours. The average cooling rate in this case was 0.1°C / sec. Thus, a lithium storage-release material having an atomic ratio of silicon to nickel (Si / Ni ratio) of 2.5 was obtained in a yield of 99%.

Embodiment 3

[0152] Using 408.9 kg of silica as a silicon source and 245.3 kg of charcoal as a carbon source with respect to 100 kg of new nickel as a nickel source as a raw material, use figure 2 The method described in the production flow chart shown produces a lithium occlusion-release material. Cooling of the molten mass was performed by cooling from the molten state to 50° C. over 3 hours. The average cooling rate in this case was 0.1°C / sec. Thus, a lithium storage-release material having an atomic ratio of silicon to nickel (Si / Ni ratio) of 4.0 was obtained in a yield of 99%. The size of the Si phase measured in the same manner as in Measurement Example 3 was 84 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com