Cultivation method for improving survival rate of big bruguiear gymnorrhiza seedling transplanting

A technology of transplanting survival rate and cultivation method, which is applied in the field of cultivation to improve the transplanting survival rate of large seedlings of Lavender, can solve the problems of low survival rate of Lamella transplanting, inability to adapt to planting requirements of Lamella, and long time for cultivating large seedlings, etc. To achieve the effect of favorable growth and reproduction, maintenance of biodiversity, and good soil air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of modified sodium lignosulfonate

[0035] S1 Dissolve sodium lignosulfonate in water to prepare an aqueous solution of sodium lignosulfonate with a mass percent concentration of 35%, heat it to 95°C, keep the temperature at a constant temperature for 35 minutes, then add propylenediamine, the amount of propylenediamine added is lignin 50% of the total volume of the sodium sulfonate aqueous solution, then dropwise add glutaraldehyde, the addition of the glutaraldehyde is 85% of the total volume of propylenediamine, and react at a temperature of 80°C for 2h to obtain modified lignosulfonic acid sodium solution;

[0036] S2 extracts the modified sodium lignosulfonate solution obtained in step S1 with absolute ethanol to obtain an extract, washes the extract with petroleum ether, and freeze-dries after washing. The freeze-drying conditions are:- Pre-freeze at 6°C for 2 hours, then freeze at -18°C for 18 hours at a vacuum of 0.06mPa to obtain ...

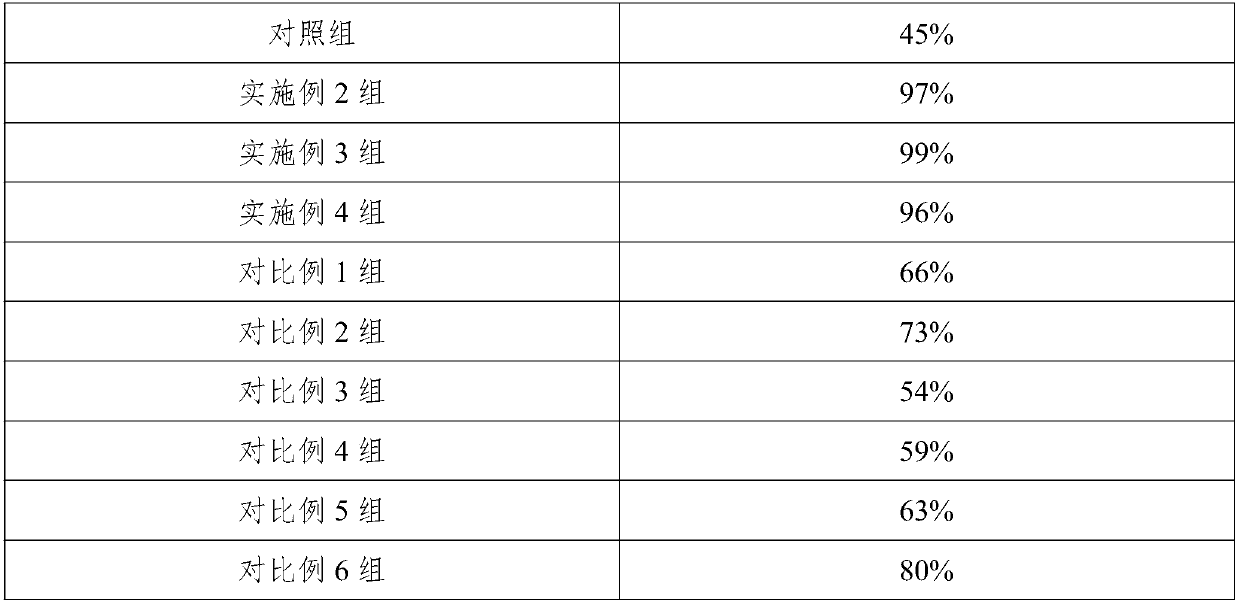

Embodiment 2

[0037] Embodiment 2, nutrient soil of the present invention

[0038] Described nutrient soil is made up of following composition and parts by weight thereof:

[0039] 35 parts of sea mud, 8 parts of peat soil, 20 parts of activated sludge, 18 parts of plant ash, 8 parts of sodium alginate, 4 parts of loosening agent, 4 parts of phoxim, 8 parts of potassium dihydrogen phosphate and 10 parts of calcium chloride; The sludge sedimentation ratio of the activated sludge is 18-22%, the sludge volume index is 90-95ml / g, and the dissolved oxygen in the effluent of the secondary sedimentation tank is 1.2-1.8mg / L; the loosening agent is composed of tripolyphosphoric acid Sodium and modified sodium lignosulfonate are composed in a mass ratio of 4:3; the modified sodium lignosulfonate is the modified sodium lignosulfonate prepared in Example 1.

[0040] The above-mentioned sea mud, peat soil, activated sludge, plant ash and loosening agent are first mixed uniformly, then sodium alginate, ...

Embodiment 3

[0041] Embodiment 3, nutrient soil of the present invention

[0042] Described nutrient soil is made up of following composition and parts by weight thereof:

[0043] 40 parts of sea mud, 10 parts of peat soil, 25 parts of activated sludge, 22 parts of plant ash, 8 parts of sodium alginate, 6 parts of loosening agent, 5 parts of phoxim, 9 parts of potassium dihydrogen phosphate and 12 parts of calcium chloride; The sludge sedimentation ratio of the activated sludge is 18-22%, the sludge volume index is 90-95ml / g, and the dissolved oxygen in the effluent of the secondary sedimentation tank is 1.2-1.8mg / L; the loosening agent is composed of tripolyphosphoric acid Sodium and modified sodium lignosulfonate are composed in a mass ratio of 5:2; the modified sodium lignosulfonate is the modified sodium lignosulfonate prepared in Example 1.

[0044] The above-mentioned sea mud, peat soil, activated sludge, plant ash and loosening agent are first mixed uniformly, then sodium alginate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com