A non-burning cigarette heated by an indirect heat source airflow

An airflow heating, indirect technology, applied in the direction of tobacco, cigar manufacturing, smoker's products, etc., can solve the problems of insufficient combustion of heat source, excessive temperature fluctuation, midway extinguishment, etc., to achieve uniform and sufficient combustion process, increase supply. effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

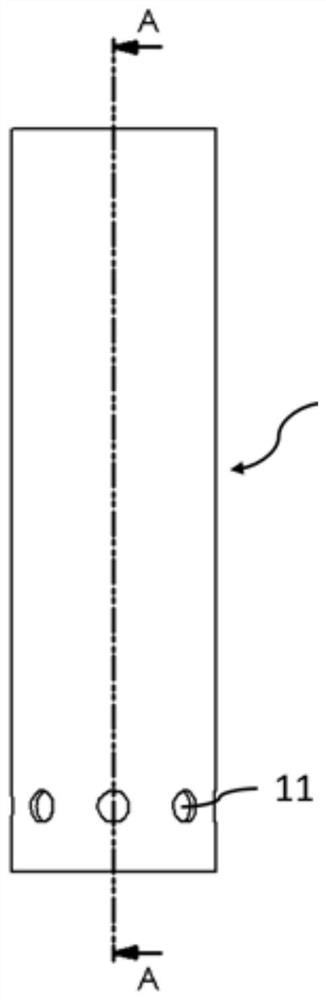

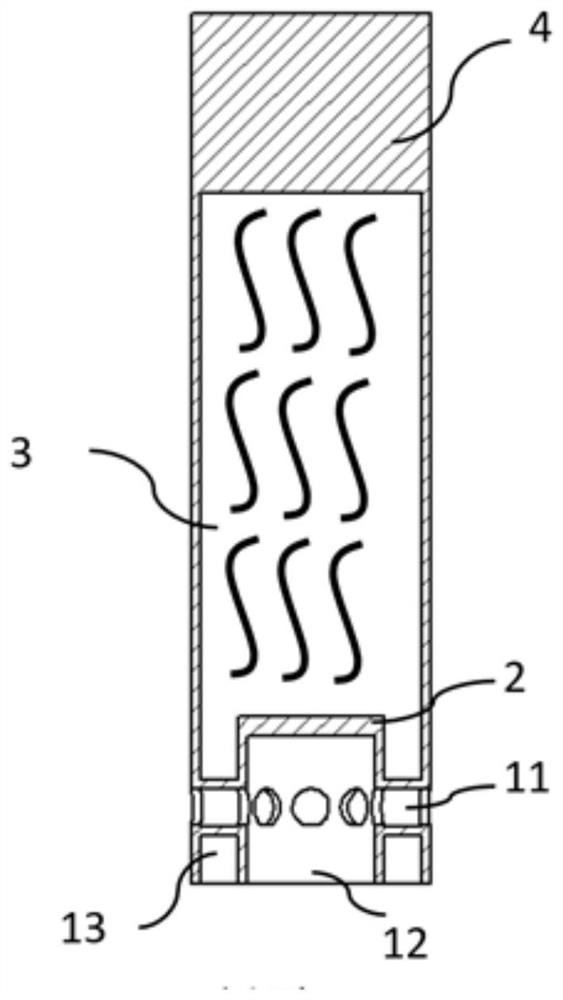

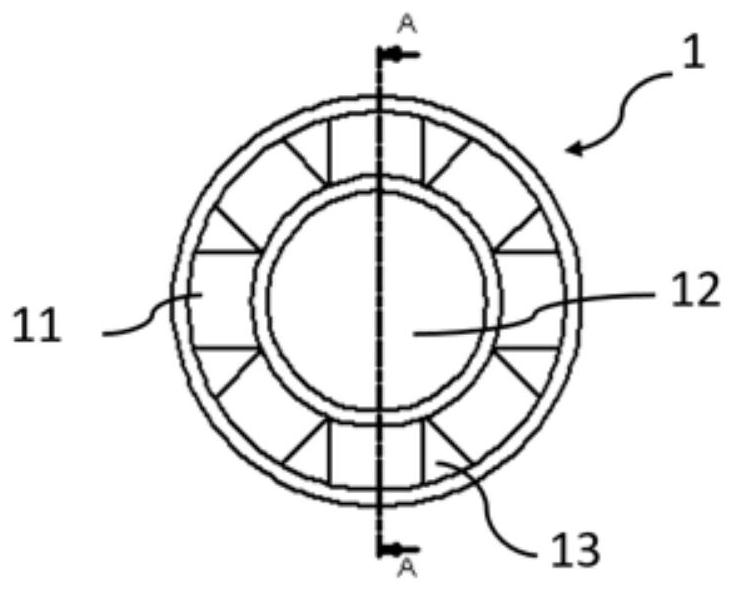

[0023] like figure 1 , figure 2 The non-burning cigarette heated by the airflow of an indirect heat source as shown includes a heating section 1, a vaporizing tobacco section 3, and a filter section 4 arranged sequentially from bottom to top, and also includes a heating section 1 and a misting tobacco section 3 Between the isolation section 2, the heating section 1 is provided with a central axial through hole 12 and a peripheral axial passage 13, and at least one radial through hole 11 is provided along the horizontal direction of the central axial through hole 12, the diameter The through holes 11 are distributed in the peripheral axial channel 13 of the central axial through hole 12, the central axial through hole 12 is used to place the heat source material, and the isolation section 2 has a central axial baffle 21 and a peripheral shaft To the through hole 22, the aerosolized tobacco segment 3 is used to accommodate aerosolizable tobacco substance.

[0024] The plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com