Small self-energy-taking ultrasonic vibration electric spindle

A technology of ultrasonic vibration and electric spindle, which is applied in the direction of fluid, electromechanical device, driving device, etc. which use vibration , The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

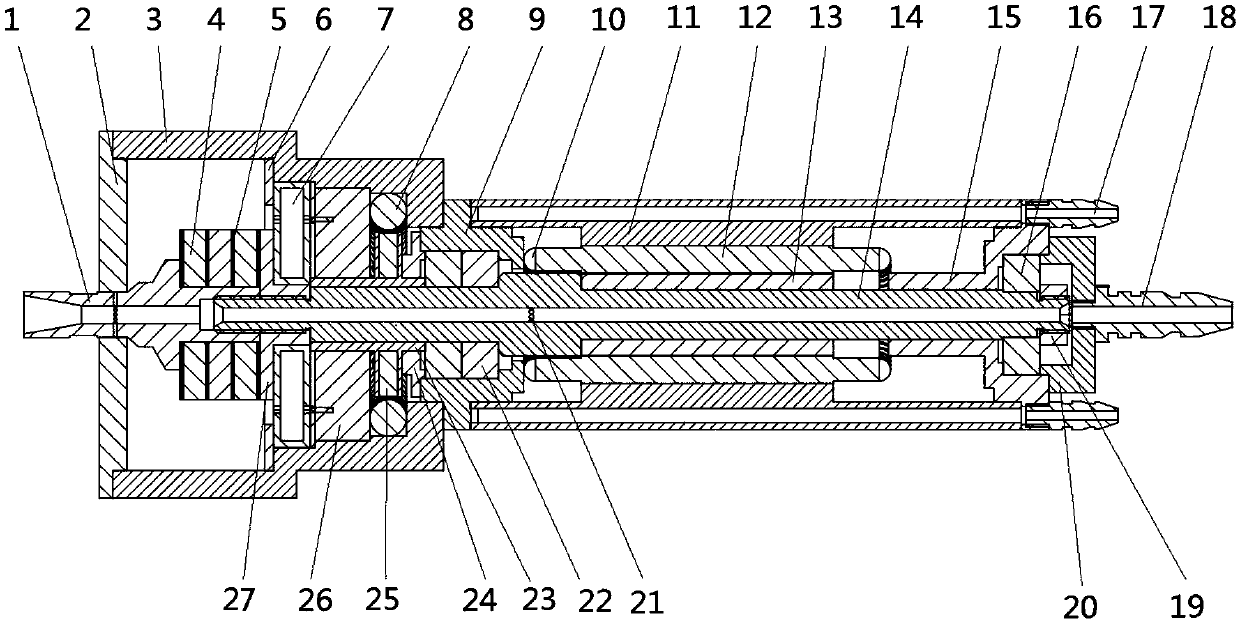

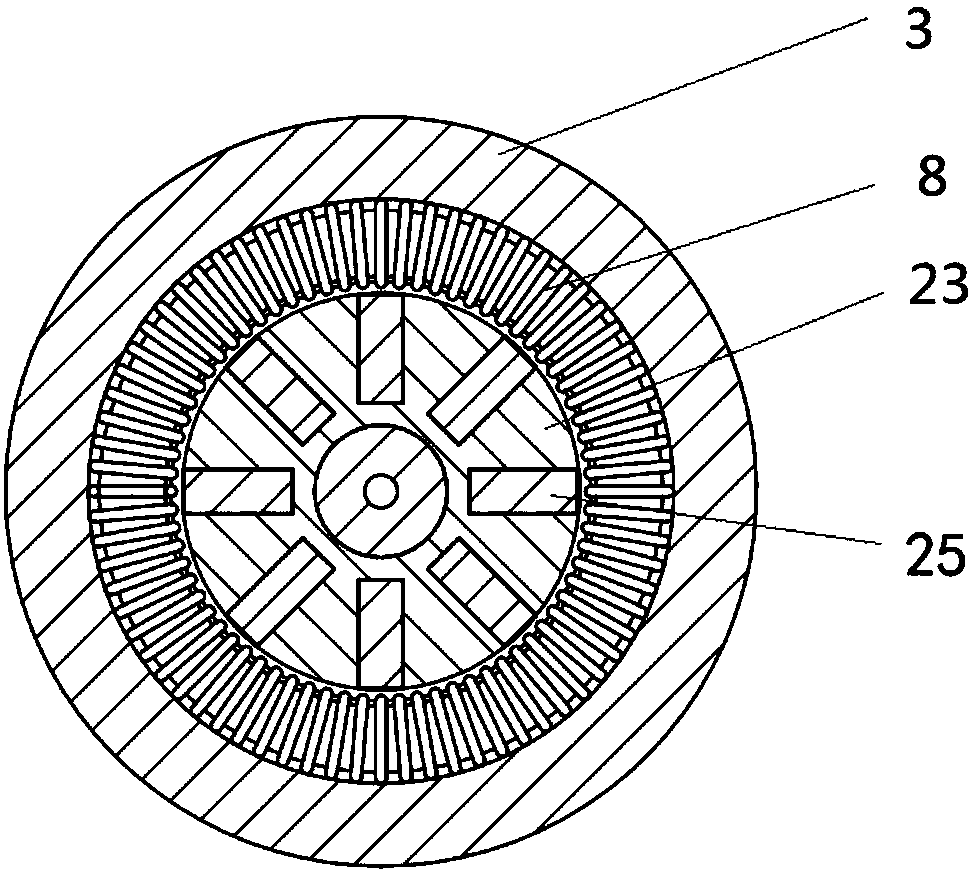

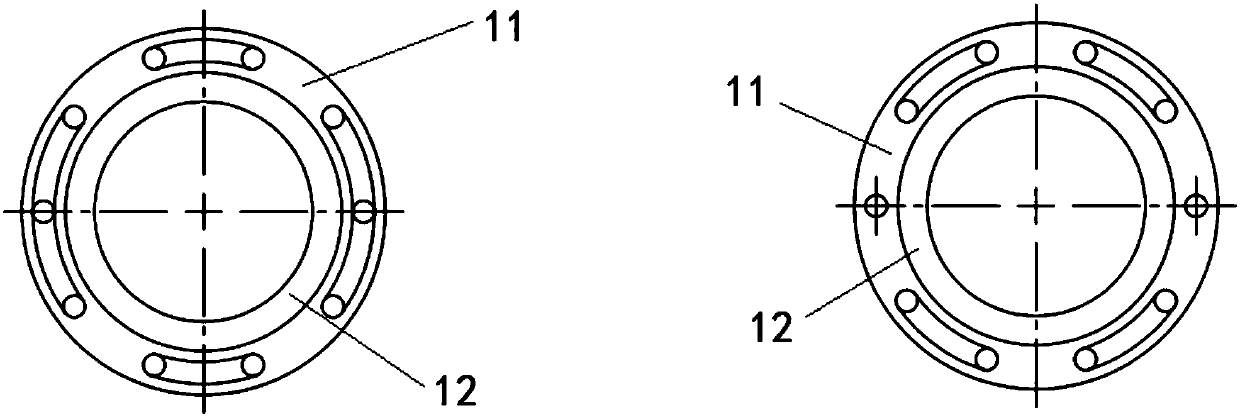

[0018] Such as figure 1 A small self-capturing ultrasonic vibration electric spindle is shown. The electric spindle includes: horn 1, end cover 2, front cover 3, piezoelectric ceramic 4, spacer 5, pressure ring 6, transformer 7, second coil 8. Inner shaft sleeve 9, first coil 10, casing 11, stator 12, rotor 13, inner shaft 14, tail bearing bracket 15, first angular contact bearing 16, imported cooling nozzle 17, large cooling nozzle 18, screw thread Pressure ring 19, tail gland 20, through hole 21, second angular contact bearing 22, magnet mounting frame 23, bearing pressure ring 24, magnet 25, circuit board 26 and piezoelectric ceramic support frame 27. A stator 12, a rotor 13 and an inner shaft 14 are sequentially arranged inside the casing 11, a second coil 8 is arranged at one end of the stator 12, and the rotor 13 is fixed with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com