Antifouling atactic polypropylene and modified superhigh-molecular-weight polyethylene composite pipe

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the field of composite pipes, to achieve the effects of preventing secondary pollution, improving anti-fouling performance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

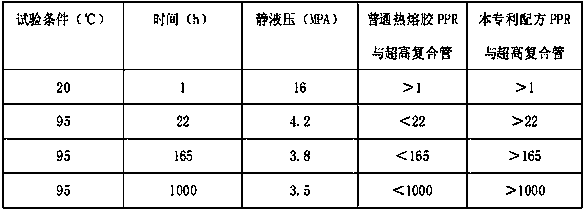

Examples

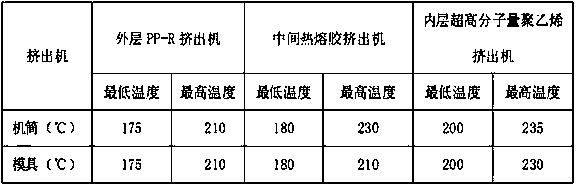

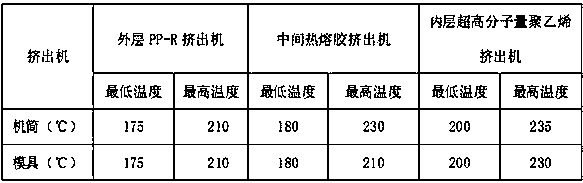

Embodiment 1

[0021] a) Preparation of compounded hot melt adhesive: put 6 kg of silane cross-linked modified polyethylene, 50 kg of maleic anhydride modified polyethylene, and 38 kg of maleic anhydride modified polypropylene in a mixer and stir for 3 minutes, then add 2 kg of butyl titanate was stirred for 5 minutes;

[0022] b) Preparation of PP-R outer layer formula: 100 kg of random copolymerized polypropylene, 2 kg of black masterbatch, stirred for 5 minutes and left to stand for use;

[0023] c) Preparation of modified ultra-high molecular weight polyethylene inner layer formula:

[0024] Step 1: Preparation of nano-titanium dioxide antibacterial masterbatch:

[0025] Put 50 kilograms of granular Type II PERT in a mill and grind it into powder, then mix 50 kilograms of PERT powder, 10 kilograms of nano-titanium dioxide, and 2 kilograms of PE wax in a high-mixer for 6 minutes. The stirred raw materials are poured into the twin-screw granulator for granulation, and the nano-titanium d...

Embodiment 2

[0031] a) Preparation of compounded hot melt adhesive: put 7.5 kg of silane cross-linked modified polyethylene, 40 kg of maleic anhydride modified polyethylene, and 25 kg of maleic anhydride modified polypropylene in a mixer and stir for 3 minutes, then add 3 kg of butyl titanate was stirred for 5 minutes.

[0032] b) Preparation of PP-R outer layer formula: 100 kg of random copolymerized polypropylene and 3 kg of black masterbatch were stirred for 5 minutes and left to stand for use.

[0033] c) Preparation of modified ultra-high molecular weight polyethylene inner layer formula:

[0034] Step 1: Preparation of nano-titanium dioxide antibacterial masterbatch:

[0035] Put 50 kilograms of granular Type II PERT in a mill and grind it into powder, then mix 50 kilograms of PERT powder, 10 kilograms of nano-titanium dioxide, and 2 kilograms of PE wax in a high-mixer for 6 minutes. The stirred raw materials are poured into the twin-screw granulator for granulation, and the nano-t...

Embodiment 3

[0041] a) Preparation of compound hot melt adhesive: put 4 kg of silane cross-linked modified polyethylene, 40 kg of maleic anhydride modified polyethylene, and 30 kg of maleic anhydride modified polypropylene in a mixer and stir for 3 minutes, then add 3.5 kg of butyl titanate was stirred for 5 minutes.

[0042] b) Preparation of PP-R outer layer formula: 100 kg of random copolymerized polypropylene and 4 kg of black masterbatch were stirred for 5 minutes and left to stand for use.

[0043] c) Preparation of modified ultra-high molecular weight polyethylene inner layer formula:

[0044] Step 1: Preparation of nano-titanium dioxide antibacterial masterbatch:

[0045] Put 50 kilograms of granular Type II PERT in a mill and grind it into powder, then mix 50 kilograms of PERT powder, 10 kilograms of nano-titanium dioxide, and 2 kilograms of PE wax in a high-mixer for 6 minutes. The stirred raw materials are poured into the twin-screw granulator for granulation, and the nano-tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com