A kind of production method of sauce-flavored wine

A production method, the technology of Maotai-flavored wine, which is applied in the production field of Maotai-flavored wine, can solve the problems of affecting the temperature of distilled wine, the accumulation is too old and too tender, and the accumulation is slow to heat up, so as to achieve the improvement of liquor yield and the improvement of liquor body. The effect of improving the quality of clean and burnt aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

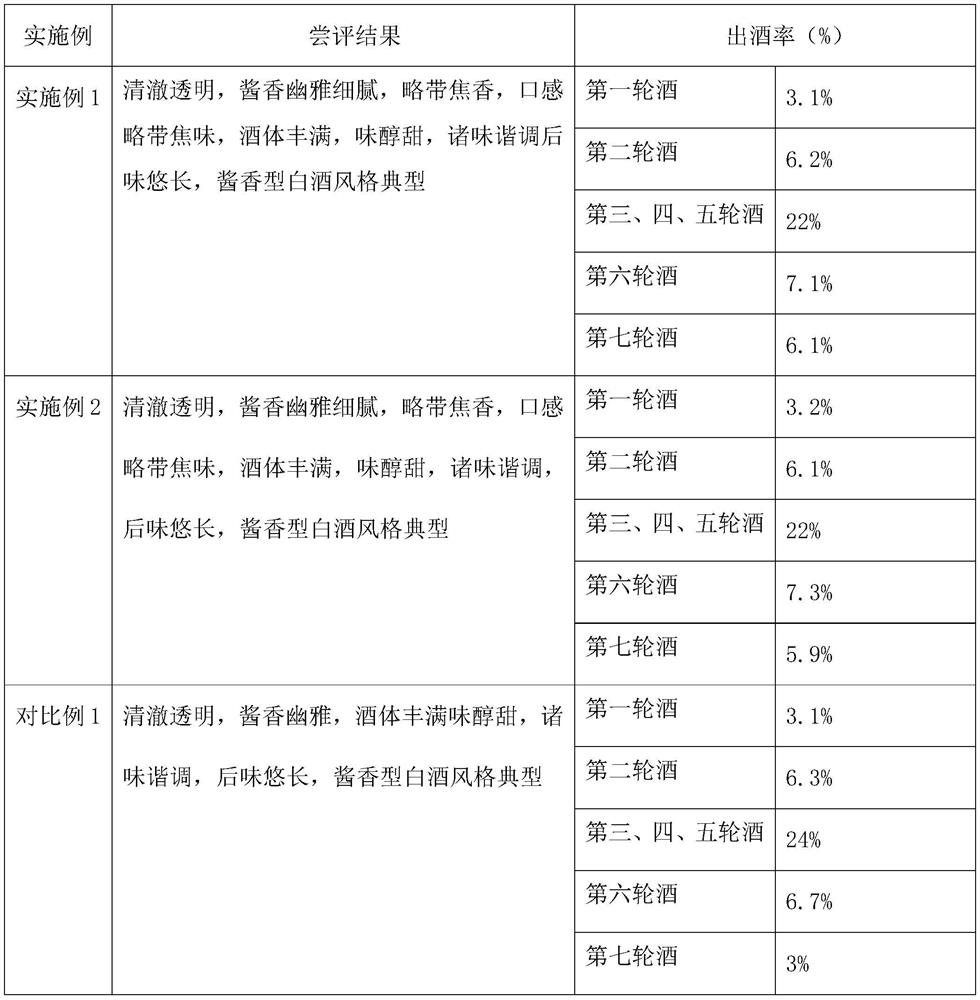

Examples

Embodiment 1

[0028] 1) Select 100Kg plump whole-grain sorghum, divide it into two equal parts, one part is the raw material for sanding, and the other part is the raw material for rough sand, and the two parts of raw materials are followed by the following steps 2)-step 5);

[0029] 2) Grain soaking: Soak 50Kg of whole sorghum in hot water at 90°C for 24 hours;

[0030] 3) steamed grain: soaked sorghum is steamed in a retort, so that the gelatinization rate of sorghum reaches 90%, after the retort is released, water is sprinkled to replenish water until the water content of the grain reaches 41%, and then the retort is taken out to spread to air;

[0031] 4) Accumulation and fermentation: Add Daqu, which accounts for 8% of the mixed raw materials, to the air-dried grain. The temperature for making koji is 70°C. After stirring evenly, stack and ferment for 5 days until the temperature of the upper pile reaches 55°C;

[0032] 5) Fermentation in the pond: After accumulation and fermentation, ...

Embodiment 2

[0036] 1) Choose 100Kg plump whole-grain sorghum, divide it into two equal parts, one part is the raw material for lowering sand, and the other part is the raw material for rough sand, and the two parts of raw materials are followed by the following steps 2)-step 5);

[0037] 2) Grain soaking: put 50Kg of whole sorghum into hot water at 80°C for 28 hours;

[0038] 3) steamed grain: soaked sorghum is steamed in a retort, so that the gelatinization rate of sorghum reaches 90%, after the retort is released, water is sprinkled to replenish water until the water content of the grain reaches 41%, and then the retort is taken out to spread to air;

[0039] 4) Accumulation fermentation: add 12% of the mixed raw material to the grain after drying, Daqu, the temperature of the koji making is 70 ° C, after stirring evenly, accumulation and fermentation for 7 days, until the temperature of the upper stack reaches 55 ° C;

[0040] 5) Fermentation in the pond: After accumulation and ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com