Method for measuring high-silicon high-carbon steel wire rod austenite grain size

A technology of austenite grains and measurement methods, which is applied in measurement devices, particle size analysis, particle and sedimentation analysis, etc. Clear and successful results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

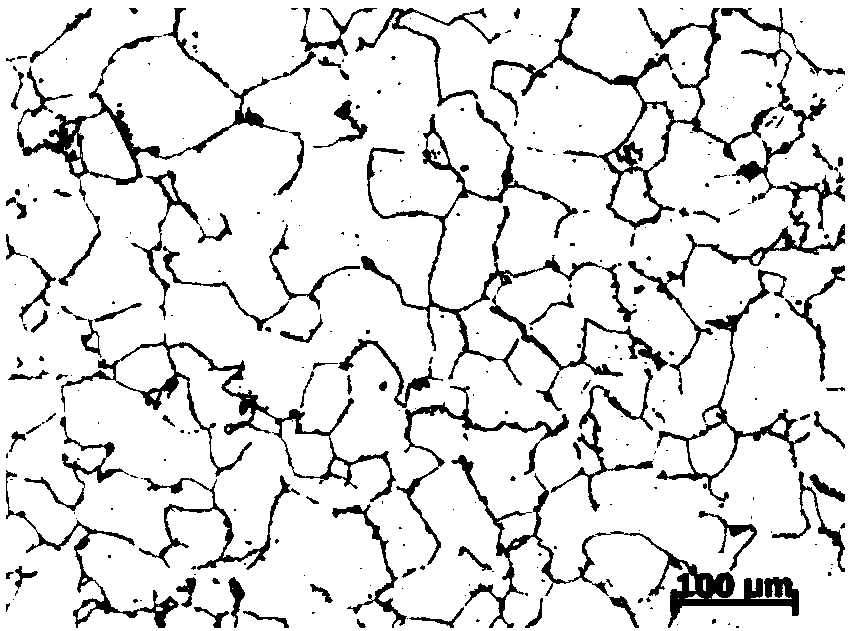

[0023] Process the wire rod into a round bar with a length of 10cm and a diameter of 6mm; heat the round bar on a thermal simulation testing machine to 980°C, keep it for 10 minutes, then cool it to 700°C at a speed of 30K / s, keep it for 10 minutes, and finally cool it down to room temperature quickly ; cut the heat-treated sample along the cross-section at the position of the welding thermocouple, then inlay, grind and polish it into a metallographic sample; rinse and dry it after corroding with sodium picrate aqueous solution for 2 minutes at 50°C; use a metallographic microscope to measure the crystal grain size, such as figure 1 As shown, the average grain size of the grains was measured to be 50 μm.

Embodiment 2

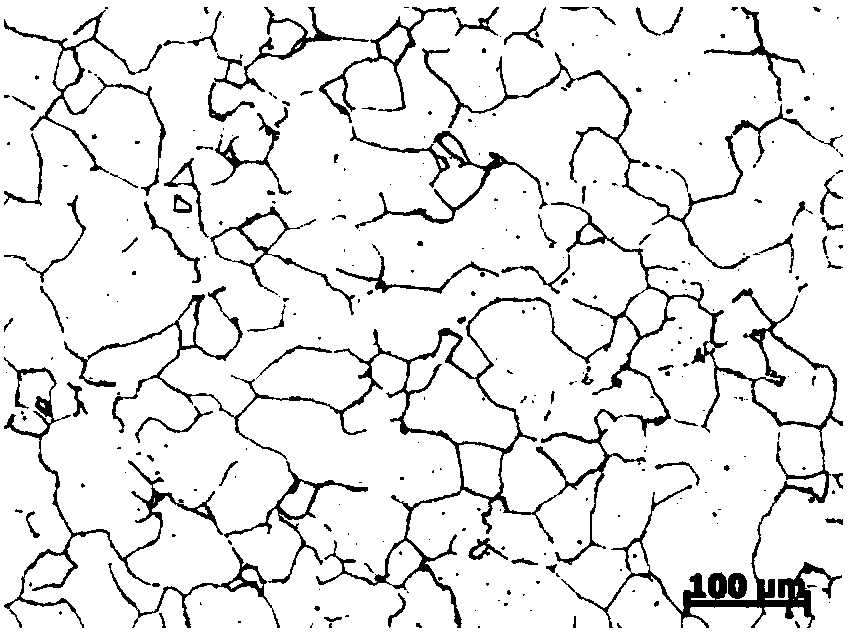

[0025] Process the wire rod into a round bar with a length of 10cm and a diameter of 6mm; heat the round bar on a thermal simulation testing machine to 1050°C, keep it for 10 minutes, then cool it to 720°C at a speed of 30K / s, keep it for 10 minutes, and finally cool it down to room temperature quickly ; cut the heat-treated sample along the cross-section at the position of the welding thermocouple, then inlay, grind and polish it into a metallographic sample; rinse and dry it after corroding with sodium picrate aqueous solution for 2 minutes at 50°C; use a metallographic microscope to measure the crystal grain size, such as figure 2 As shown, the average grain size of the grains was measured to be 56 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com