Epoxy resin composition

A technology of epoxy resin and composition, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problem of inability to cope with heat curing, and achieve the effect of excellent bonding strength and pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

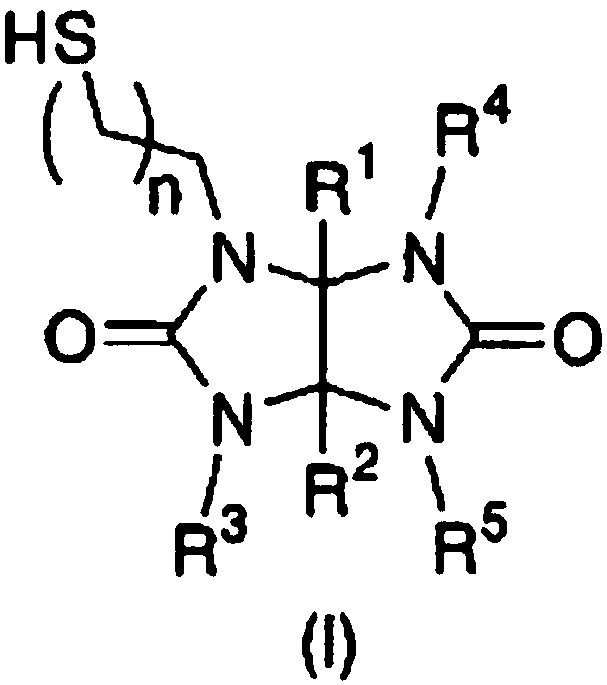

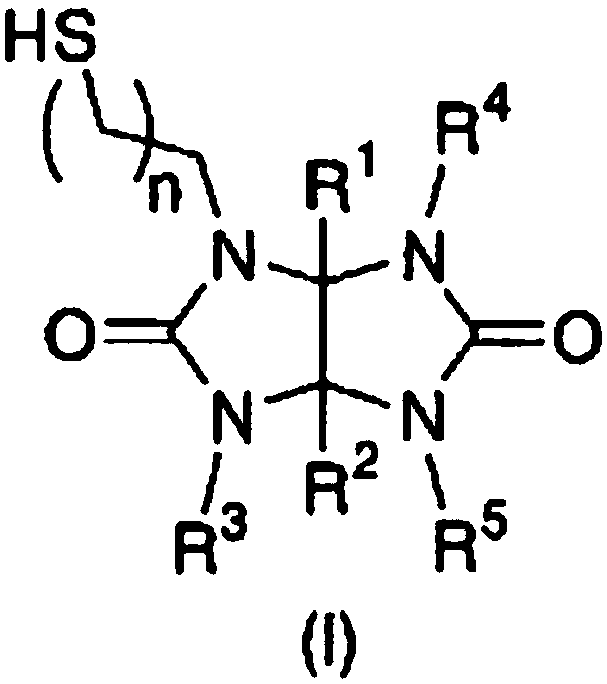

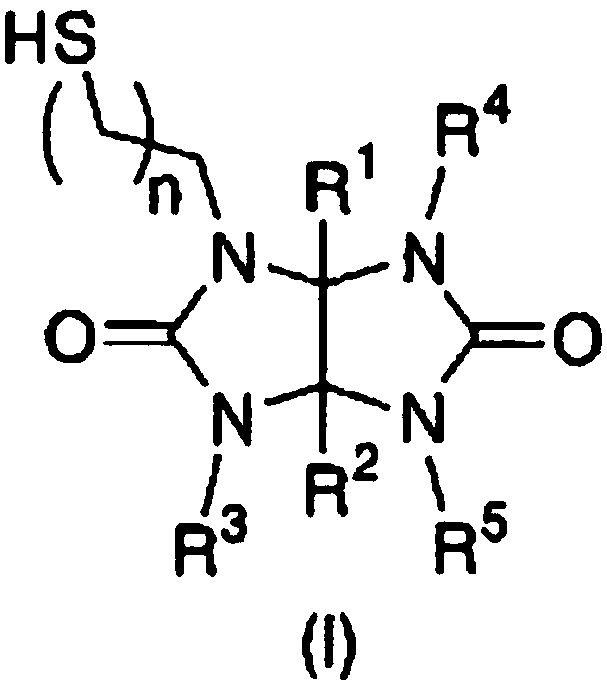

Image

Examples

Embodiment 1

[0129] Example 1 is an example of using only an aromatic epoxy resin as the epoxy resin of the (A) component,

[0130] Examples 2 and 3 are examples in which an aromatic epoxy resin and an aliphatic epoxy resin are used together as the epoxy resin of the (A) component and a thickening inhibitor is added as the (D) component, and Example 4 is changed as ( An example of an aromatic epoxy resin used as the epoxy resin of component A, and Example 5 is an isocyanate adduct-type microcapsule containing DABCO as an active ingredient that was used as component (C) instead of Example 4. Example 6 and 7 are examples of changing the thiol-based curing agent of the (B) component to Example 4, and Example 8 is an example of adding a thickening inhibitor to Example 4 as (D) As examples of components, Examples 9 to 11 are examples in which the thickening inhibitor of the component (D) was changed from Example 8.

[0131] These examples are all capable of low-temperature short-time curing at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com