Expanded graphite powder water-based tunnel fire retardant coating and using method

A technology of expanded graphite powder and fire retardant coating, applied in fire retardant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor water resistance and unsatisfactory fire resistance limit of the paint film, and enhance the fire resistance and chemical resistance of the paint film. High performance, strong thermal insulation effect and high expansion factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

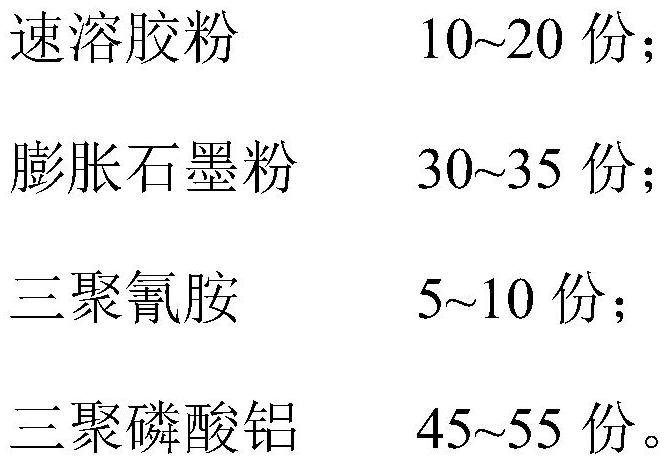

[0025]A kind of expanded graphite powder water-based tunnel fireproof coating, according to the number of mass parts, the coating is composed of the following components: vinegar acrylic instant glue powder 20 parts; 35 parts of intumestant graphite powder; Melamine 10 parts; Aluminum tripophosphate 55 parts. The raw material components are mixed uniformly in a 1:1 ratio with water as a dispersion medium, removing the unstable components of the concrete structure surface, and spraying the paint on the tunnel concrete surface.

Embodiment 2

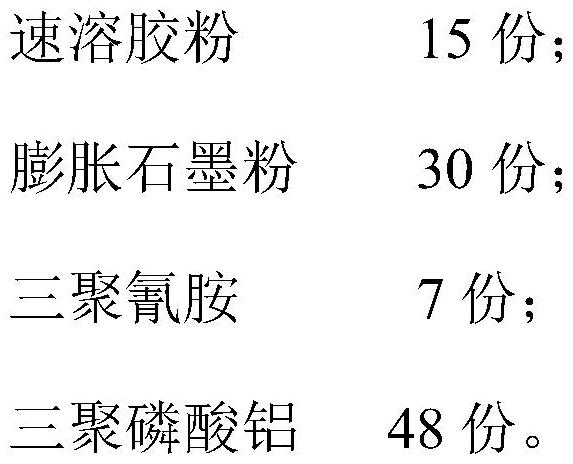

[0027] A kind of intumescent graphite powder water-based tunnel fireproof coating, according to the number of mass parts, the coating is composed of the following components: 15 parts of styrene-propylene instant glue powder; 30 parts of expanded graphite powder; Melamine 7 parts; Aluminum tripophosphate 48 parts. The raw material components are mixed uniformly in a 1:1 ratio with water as a dispersion medium, removing the unstable components of the concrete structure surface and applying the paint to the tunnel concrete surface.

Embodiment 3

[0029] A kind of expanded graphite powder water-based tunnel fireproof coating, according to the number of mass parts, the coating is composed of the following components: silicon propylene instant glue powder 10 parts; 30 parts of expanded graphite powder; Melamine 5 parts; Aluminum tripophosphate 45 parts. The raw material components are mixed uniformly in a 1:1 ratio with water as a dispersion medium, removing the unstable components of the concrete structure surface, and applying the paint brush to the tunnel concrete surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com