A kind of sound-absorbing wallpaper base paper and preparation method thereof

The technology of sound wall and sea island fiber is applied in the field of sound-absorbing wallpaper base paper and its preparation, which can solve the problems of uneven sound-absorbing effect, less than ideal, and increase the complexity of wallpaper, and achieve the effect of enhancing printability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

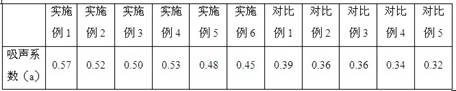

Examples

Embodiment 1

[0034] Made from the following components by weight: softwood pulp fiber 38kg, sea-island fiber 32kg, acrylic latex 10kg, polybutadiene latex 5kg, PVC paste resin 6kg, dioctyl phthalate 5kg, AC foaming agent 0.05kg ; The island-in-the-sea fiber in this embodiment is an island-in-the-sea fiber.

[0035] Preparation:

[0036] 1) Sea-island fiber pretreatment: put the sea-island fiber in an alkaline solution with a pH value of 13, stir at 98°C for 2 hours, then wash with water for later use;

[0037] 2) Mix the wood pulp fiber and the treated sea-island fiber into a beater, add water to dilute the beating, and the beating degree is 30°SR to obtain the pulp;

[0038] 3) The slurry obtained in step 2) is copied and dried by a fourdrinier paper machine to obtain a semi-finished base paper;

[0039] 4) Sizing machine sizing;

[0040] 5) Heat the plasticizer to 35°C, add PVC paste resin and foaming agent during the stirring process, and continue stirring for 30 minutes to obtain th...

Embodiment 2

[0044] Prepared by the following components by weight: 38kg of hardwood pulp fiber, 32kg of sea-island fiber, 15kg of acrylic latex, 6kg of PVC paste resin, 5kg of dioctyl phthalate, and 0.05kg of AC foaming agent; the sea-island fiber of this embodiment is Fixed island type sea island fiber.

[0045] Preparation:

[0046] 1) Sea-island fiber pretreatment: put the sea-island fiber in an alkaline solution with a pH value of 13, stir at 98°C for 2 hours, then wash with water for later use;

[0047] 2) Mix the wood pulp fiber and the treated sea-island fiber into a beater, add water to dilute the beating, and the beating degree is 30°SR to obtain the pulp;

[0048] 3) The slurry obtained in step 2) is copied and dried by a fourdrinier paper machine to obtain a semi-finished base paper;

[0049] 4) Sizing machine sizing;

[0050] 5) Heat the plasticizer to 35°C, add PVC paste resin and foaming agent during the stirring process, and continue stirring for 30 minutes to obtain the...

Embodiment 3

[0054] Prepared by the following components in parts by weight: softwood pulp fiber 38kg, sea-island fiber 32kg, polybutadiene latex 15kg, PVC paste resin 6kg, dioctyl phthalate 5kg, AC foaming agent 0.05kg; present embodiment The sea-island fiber is an adventitious island-island fiber.

[0055] Preparation:

[0056] 1) Sea-island fiber pretreatment: put the sea-island fiber in an alkaline solution with a pH value of 12, stir at 98°C for 1.5 hours, then wash with water for later use;

[0057] 2) Mix the wood pulp fiber and the treated sea-island fiber into a beater, add water to dilute the beating, and the beating degree is 30°SR to obtain the pulp;

[0058] 3) The slurry obtained in step 2) is copied and dried by a fourdrinier paper machine to obtain a semi-finished base paper;

[0059] 4) Sizing machine sizing;

[0060] 5) Heat the plasticizer to 35°C, add PVC paste resin and foaming agent during the stirring process, and continue stirring for 30 minutes to obtain the coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com