A shaft displacement fault self-healing control device for a centrifugal compressor

A centrifugal compressor, fault self-healing technology, applied in the components of pumping device for elastic fluid, pump control, mechanical equipment, etc. and other problems to achieve the effect of reducing difficulty, realizing self-healing regulation, and preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

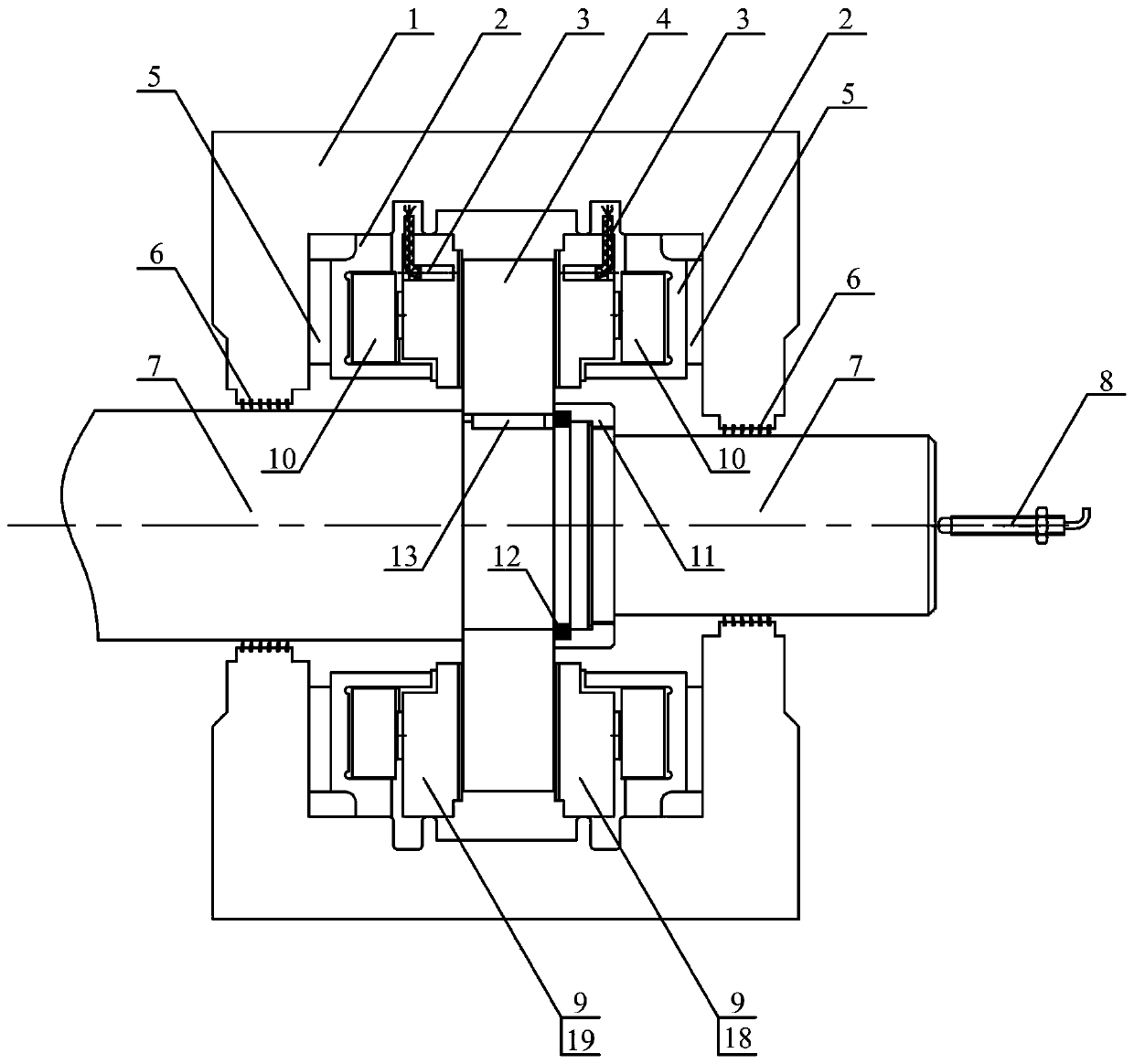

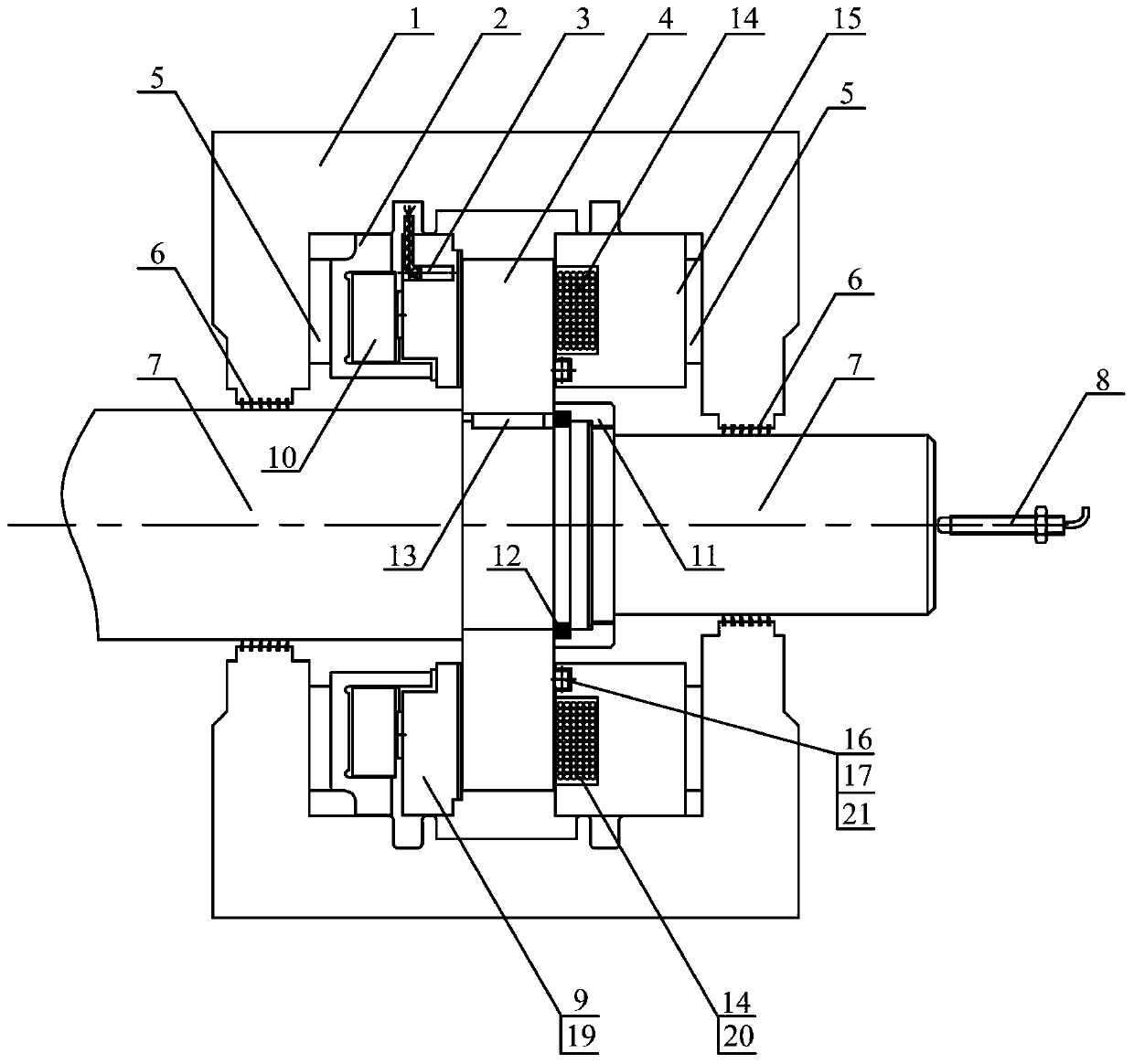

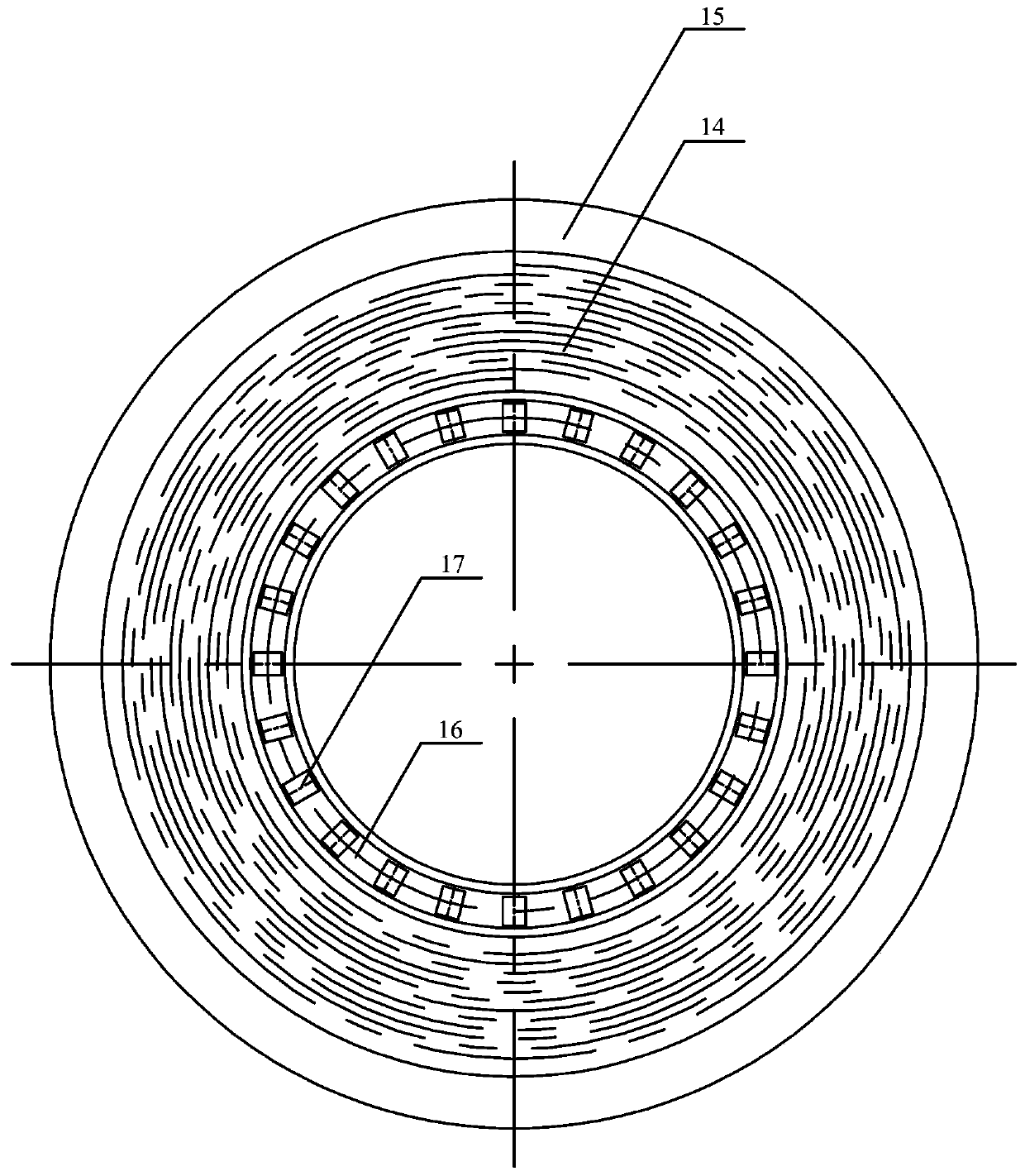

[0033] Typical thrust sliding bearing structure such as figure 1 As shown, it consists of bearing body 1, thrust plate 4, shaft end seal 6, shaft 9, main thrust sliding bearing 19 and auxiliary thrust sliding bearing 18. The main thrust sliding bearing 19 and the auxiliary thrust sliding bearing 18 are all composed of the lower leveling block 2, the thrust bearing bush 9, the upper leveling block 10, and the adjustment pad 5 at the main thrust sliding bearing 19 and the auxiliary thrust sliding bearing 18. The thrust plate 4, the main thrust sliding bearing 19 and the auxiliary thrust sliding bearing 18 are all installed on the bearing body 1. The thrust plate 4 is fixed on the shaft 7 through a locking ring 11 , a collar 12 and a key 13 . The main thrust sliding bearing 19 and the auxiliary thrust sliding bearing 18 are on both sides of the thrust plate 4, and there is no friction between them. The inside of the bearing body 1 is filled with a lubricating liquid medium, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com