Concrete pump tube vibration-damping and fixing system

A technology for concrete pump pipes and fixing systems, which is applied in the directions of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of hidden quality problems of buildings, no effective buffering of the impact force of the pump pipes, and disorder, etc. Rigid destruction effect, saving fixing time, reducing noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

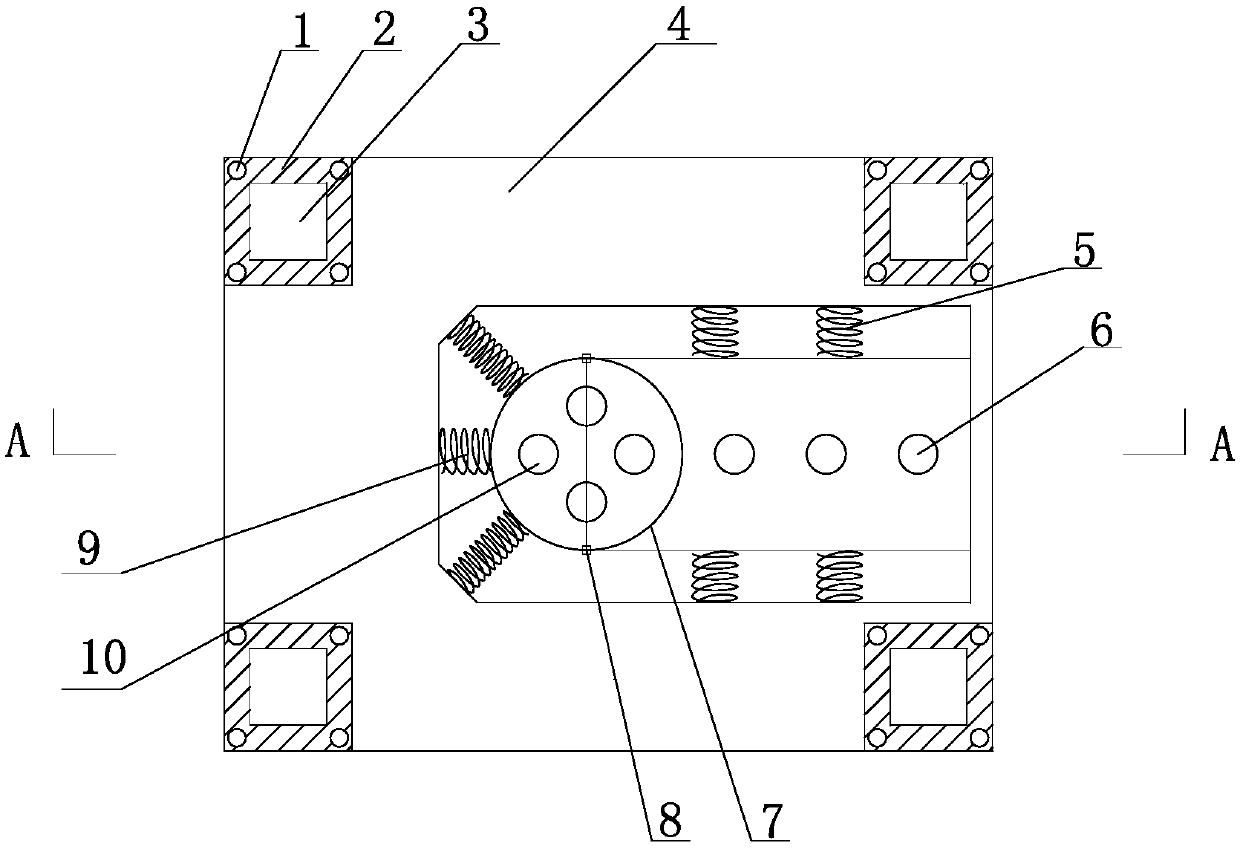

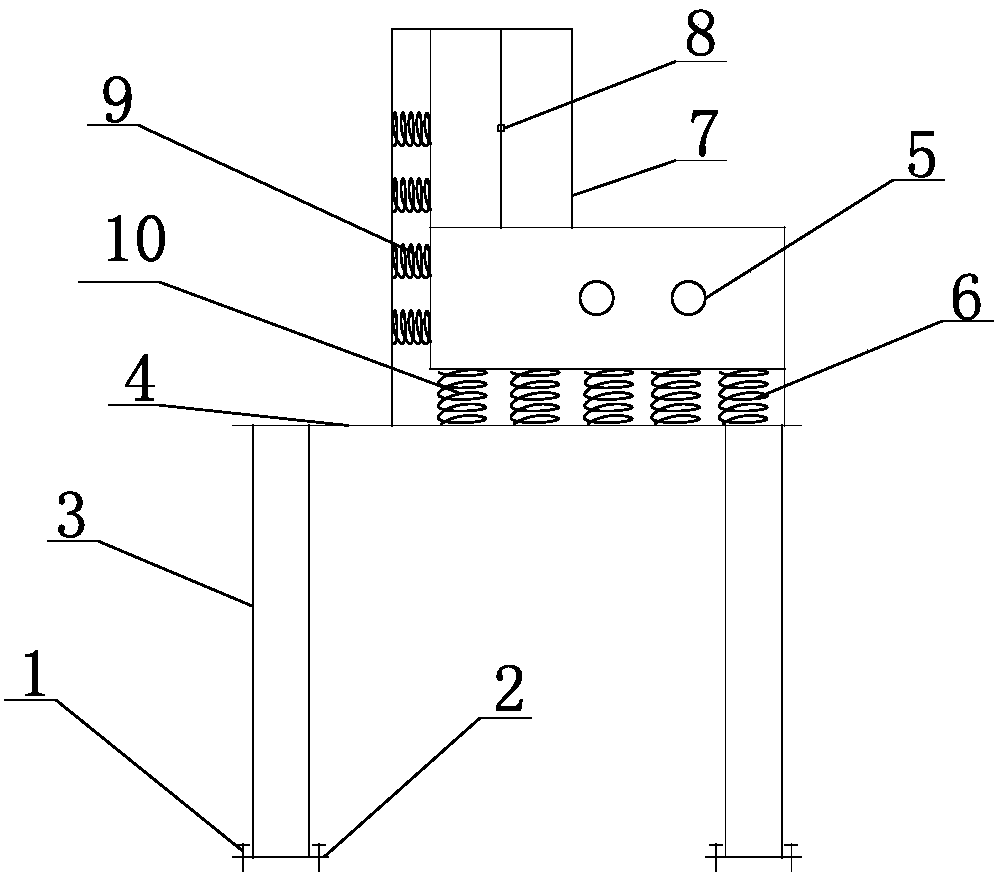

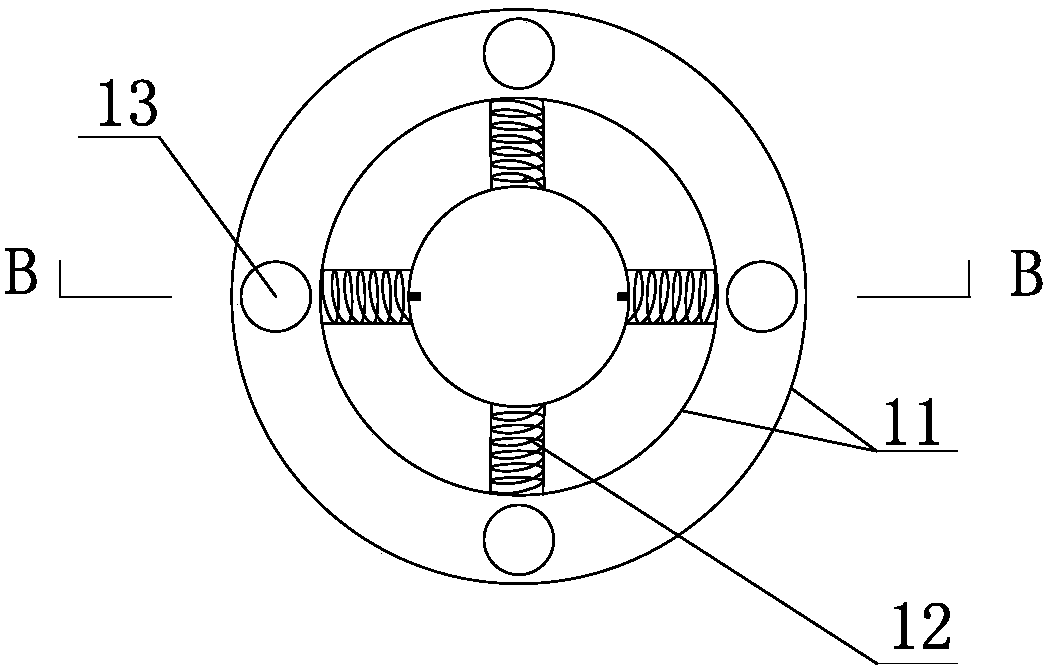

[0030] Such as Figure 1 ~ Figure 4 As shown, the concrete pump pipe vibration damping fixing system according to the present invention includes a pump pipe vibration damping fixing support and a pump pipe vibration damping fixing device. Fixing assembly, corner vibration damping The fixing assembly includes a vibration-damping housing, which is fixed on the support frame, and the vibration-damping housing includes a horizontal tube installation cavity and a vertical tube installation cavity perpendicular to the horizontal tube installation cavity, where the horizontal tube is installed The outer circumference of the chamber and the vertical pipe installation chamber are equipped with horizontal vibration damping elements, and the bottom of the horizontal pipe installation chamber is equipped with vertical vibration damping elements; the pump pipe vibration damping fixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com