Liquid crystal display mother board and manufacturing method thereof

A liquid crystal display and motherboard technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult control of frame glue width precision, hinder product diversification design, limit substrate utilization rate, etc., and improve product cycle time time, is conducive to rapid development, and occupies a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

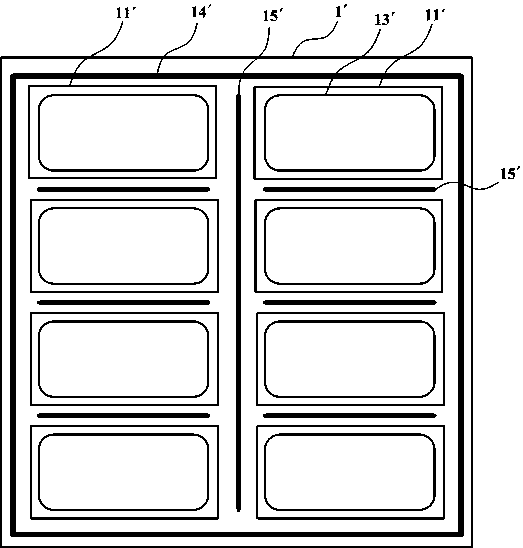

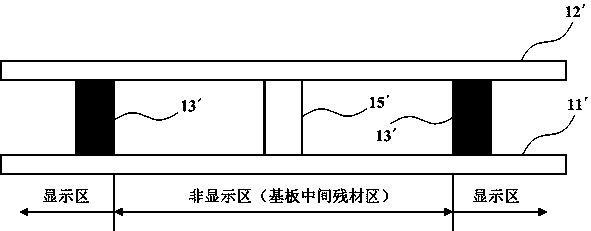

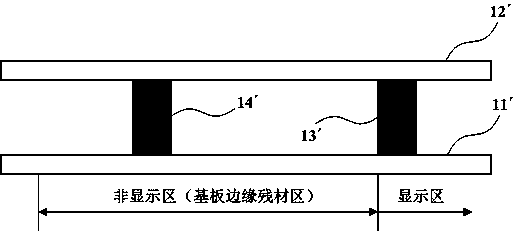

[0041] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a method for manufacturing a liquid crystal display motherboard, including:

[0042] An array substrate and a color filter substrate arranged opposite to each other are provided, and a plurality of TFT substrates arranged in an array are formed on the array substrate;

[0043] An engaging structure made of a photoresist material is provided between the array substrate and the color filter substrate, and the engaging structure is used to replace the virtual sealing frame and the ring sealing frame to support the liquid crystal display motherboard The non-display area and the residual material connecting the array substrate and the color filter substrate.

[0044] Wherein, the engaging structure is manufactured in the same manufacturing process of the array substrate or the color filter substrate as the color resist or black matrix.

[0045] From the above description, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com