Piezoelectric element, piezoelectric sensor as well as speed and displacement detecting device

A piezoelectric sensor and piezoelectric element technology, applied in the field of sensing and testing, can solve the problems of few sensors, high price, complex measurement system, etc., achieve high measurement accuracy and frequency response, improve measurement accuracy, and reduce charge leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

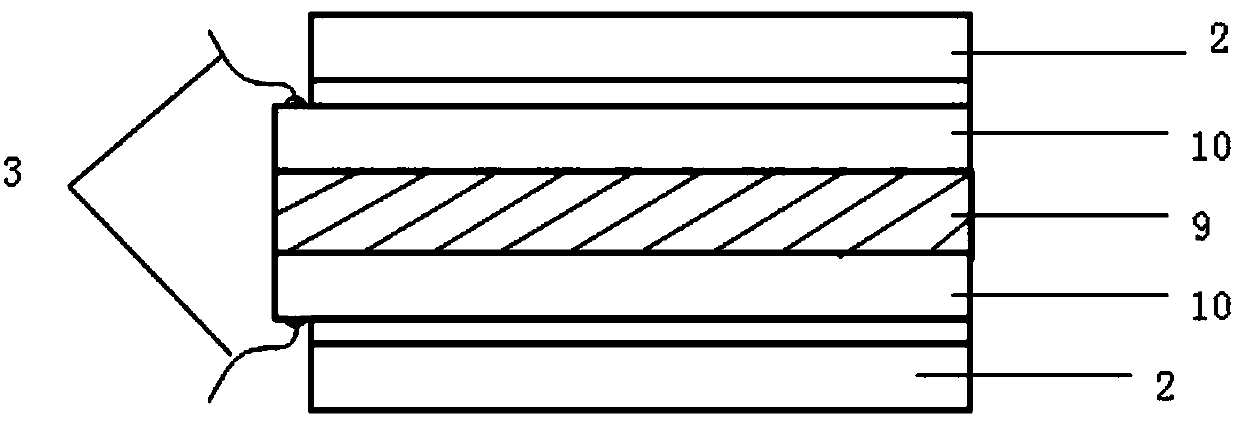

[0027] Such as figure 1 As shown, the present invention relates to a piezoelectric element based on a piezoelectric film, including a piezoelectric sheet 1, and the piezoelectric sheet 1 includes a piezoelectric film layer 9, an electrode layer 10 arranged on the upper and lower surfaces of the piezoelectric film layer 9 , and an insulating layer 2 covering the outer surface of each electrode layer 10; each electrode layer 10 leads out a signal line 3.

[0028] The piezoelectric sheet 1 has a triangular shape and is a flexible piezoelectric sheet, and the insulating layer is a flexible insulating layer. The piezoelectric film layer 9 is a PVDF piezoelectric film.

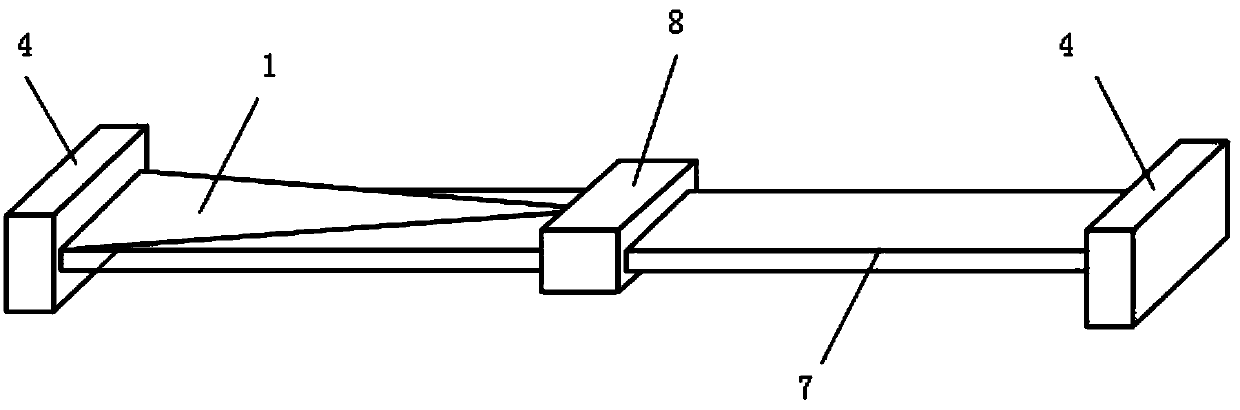

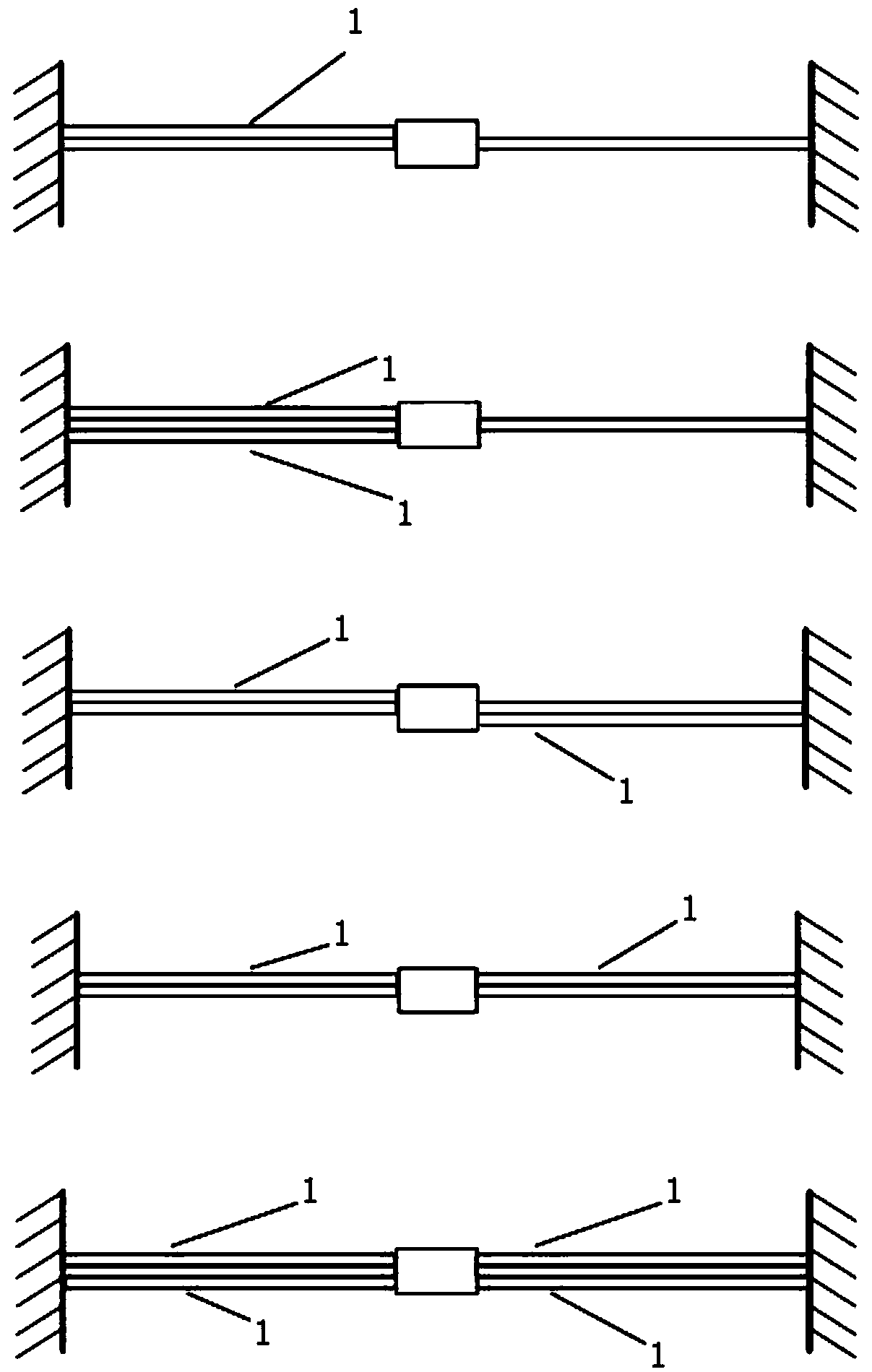

[0029] Such as figure 2 , image 3 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com