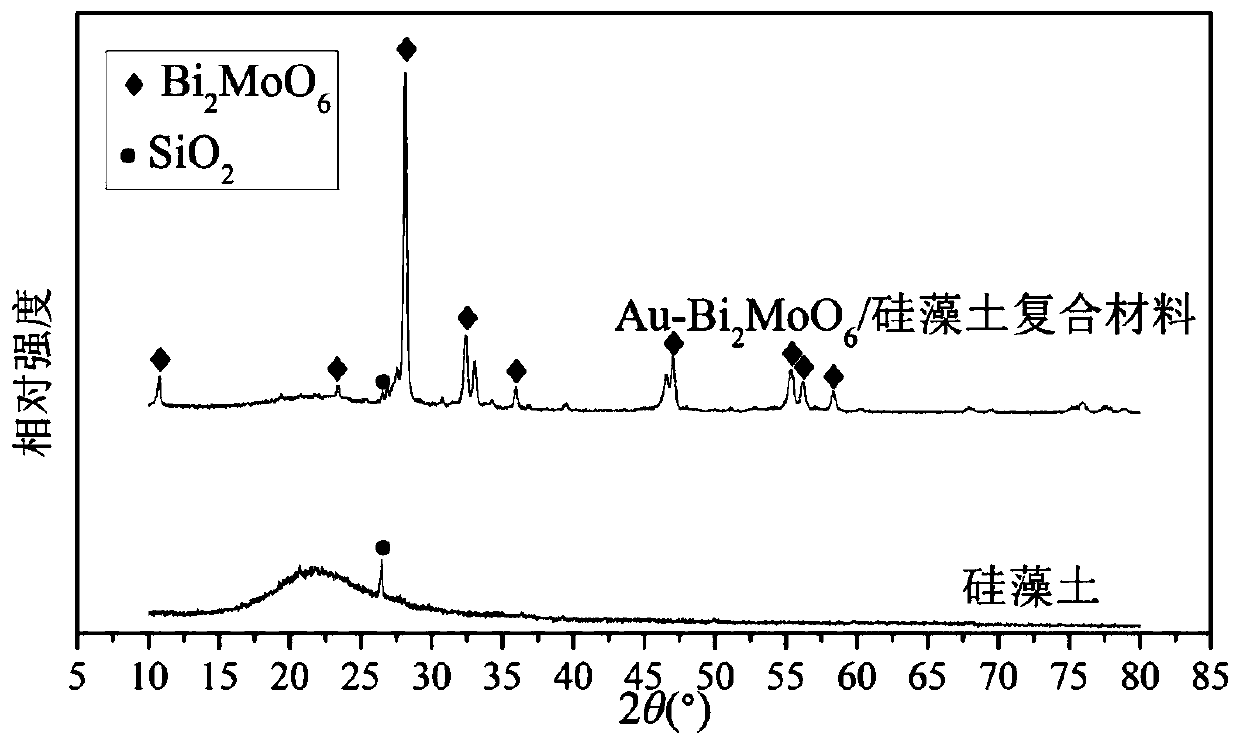

A kind of au-bi 2 moo 6 /Diatomite composite material and its preparation method and application

A technology of au-bi2moo6 and composite materials, which is applied in the field of development of new non-metallic mineral materials, can solve the problems of complex steps, poor environmental protection, and low efficiency of composite materials, and achieve the effect of high environmental protection level, short process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 1.3g of diatomaceous earth and disperse it in 6.5g of deionized water, then add 0.65g of 1% tetrachloroauric acid trihydrate (HAuCl) 4 ·3H 2 0) solution, stir and mix to obtain mixed solution A;

[0031] (2) take by weighing 1.15g of urea and dissolve it in 3.1g of deionized water to obtain mixed solution B;

[0032] (3) Weigh 0.39g Bi(NO 3 ) 3 ·5H 2O was stirred and dissolved in the mixed solution of 1.755g ethylene glycol and 0.3g glycerol to obtain mixed solution C;

[0033] (4) Weigh 0.071g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 4.26 g of deionized water to obtain mixed solution D;

[0034] (5) The mixed solution A obtained in step (1) is slowly added to the mixed solution B obtained in step (2), stirred for 2 min to obtain mixed solution E, and then the mixed solution C obtained in step (3) is slowly added to the mixed solution. In E, stir for 3min to obtain mixed solution F;

[0035] (6) Slowly add mixed solution D obtained in step (4) ...

Embodiment 2

[0037] (1) Weigh 0.8g of diatomaceous earth and disperse it in 4.8g of deionized water, then add 0.48g of 1% tetrachloroauric acid trihydrate (HAuCl) 4 ·3H 2 0) solution, stir and mix to obtain mixed solution A;

[0038] (2) take by weighing 0.64g of urea and dissolve it in 1.92g of deionized water to obtain mixed solution B;

[0039] (3) Weigh 0.3105g Bi(NO 3 ) 3 ·5H 2 0 is stirred and dissolved in the mixed solution of 1.4656g ethylene glycol and 0.1553g glycerol to obtain mixed solution C;

[0040] (4) Weigh 0.0569g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 3.869 g of deionized water to obtain mixed solution D;

[0041] (5) The mixed solution A obtained in step (1) is slowly added to the mixed solution B obtained in step (2), stirred for 3 min to obtain mixed solution E, and then the mixed solution C obtained in step (3) is slowly added to the mixed solution. In E, stir for 5min to obtain mixed solution F;

[0042] (6) Slowly add the mixed solution D obtained...

Embodiment 3

[0044] (1) Weigh 1.8g of diatomaceous earth and disperse it in 7.2g of deionized water, then add 0.9g of 1% tetrachloroauric acid trihydrate (HAuCl) 4 ·3H 2 0) solution, stir and mix to obtain mixed solution A;

[0045] (2) take by weighing 1.62g urea and dissolve it in 4.05g deionized water to obtain mixed solution B;

[0046] (3) Weigh 0.4367g Bi (NO 3 ) 3 ·5H 2 0 is stirred and dissolved in the mixed solution of 1.8778g ethylene glycol and 0.4367g glycerol to obtain mixed solution C;

[0047] (4) Weigh 0.0795g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O was dissolved in 4.452g deionized water to obtain mixed solution D;

[0048] (5) The mixed solution A obtained in step (1) is slowly added to the mixed solution B obtained in step (2), stirred for 1 min to obtain mixed solution E, and then the mixed solution C obtained in step (3) is slowly added to the mixed solution. In E, stir for 1min to obtain mixed solution F;

[0049] (6) Slowly add mixed solution D obtained in step (4) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com