High-quality environment-friendly rice processing and producing method

A rice processing and production method technology, applied in agricultural machinery and equipment, grain processing, energy-saving measures, etc., can solve the problems of easy generation of dust and noise, failure of debris to be recycled, failure to achieve energy conservation and environmental protection, etc., to achieve dust control and noise emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

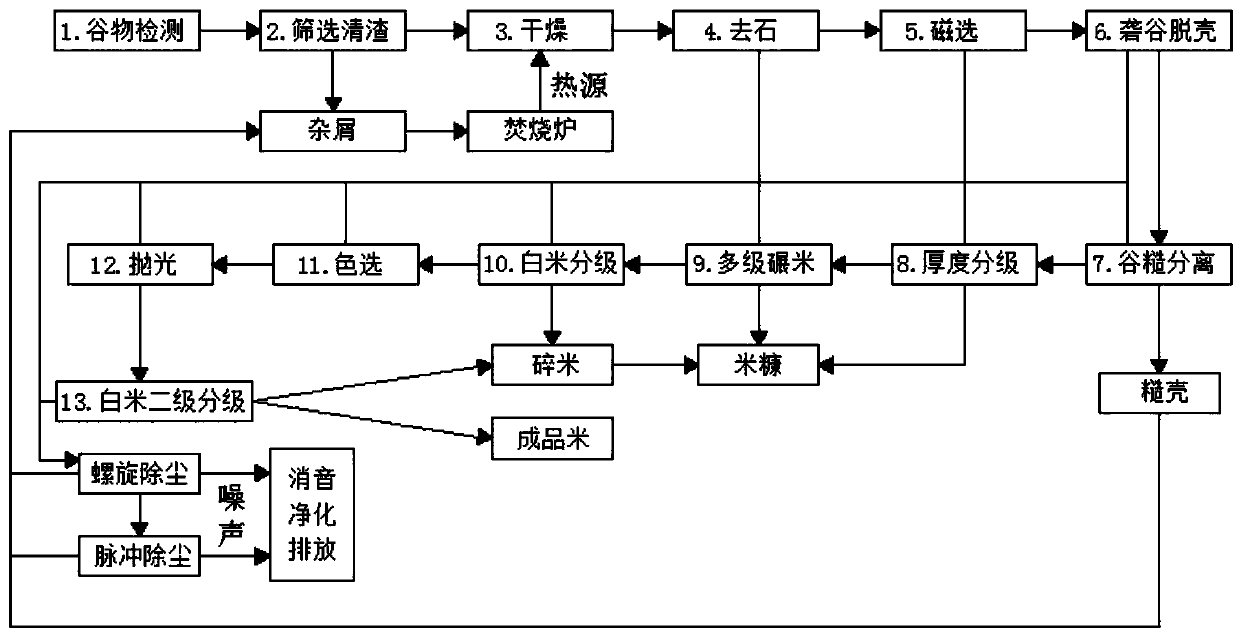

[0046] A kind of high-quality environmental protection rice processing production method, comprises the following steps:

[0047] S1. Grain testing: conduct routine testing on the harvested grains;

[0048] S2. Screening and slag removal: Put the harvested rice into the impurity removal machine to remove impurities, and then transport it to the drying room. After the screening, the impurities are transported to the incinerator of the drying system for incineration to generate heat for drying the grains. The impurities are directly transported to the incinerator for incineration as the heat source for grain drying. This method not only reduces the foreign debris dust but also saves the cost of grain drying. In order to control the direct emission of roaring noise generated by the spiral dust collector and pulse dust collector, this processing technology is A noise reduction and purification room is installed on the periphery of the workshop. The roaring noise generated by the s...

Embodiment 2

[0061] A kind of high-quality environmental protection rice processing production method, comprises the following steps:

[0062] S1. Grain testing: conduct routine testing on the harvested grains;

[0063] S2. Screening and slag removal: Put the harvested rice into the impurity removal machine to remove impurities, and then transport it to the drying room. After the screening, the impurities are transported to the incinerator of the drying system for incineration to generate heat for drying the grains. The impurities are directly transported to the incinerator for incineration as the heat source for grain drying. This method not only reduces the foreign debris dust but also saves the cost of grain drying. In order to control the direct emission of roaring noise generated by the spiral dust collector and pulse dust collector, this processing technology is A noise reduction and purification room is installed on the periphery of the workshop. The roaring noise generated by the s...

Embodiment 3

[0076] A kind of high-quality environmental protection rice processing production method, comprises the following steps:

[0077] S1. Grain testing: conduct routine testing on the harvested grains;

[0078] S2. Screening and slag removal: Put the harvested rice into the impurity removal machine to remove impurities, and then transport it to the drying room. After the screening, the impurities are transported to the incinerator of the drying system for incineration to generate heat for drying the grains. The impurities are directly transported to the incinerator for incineration as the heat source for grain drying. This method not only reduces the foreign debris dust but also saves the cost of grain drying. In order to control the direct emission of roaring noise generated by the spiral dust collector and pulse dust collector, this processing technology is A noise reduction and purification room is installed on the periphery of the workshop. The roaring noise generated by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com