Felting machine levelling roller device

A technology of paving machine and leveling, which is used in flat products, household components, household appliances, etc., can solve the problems of lateral density deviation and thickness deviation of finished MDF boards, and achieve small lateral density deviation and thickness deviation, reduce Belt consumption and power consumption, improving the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

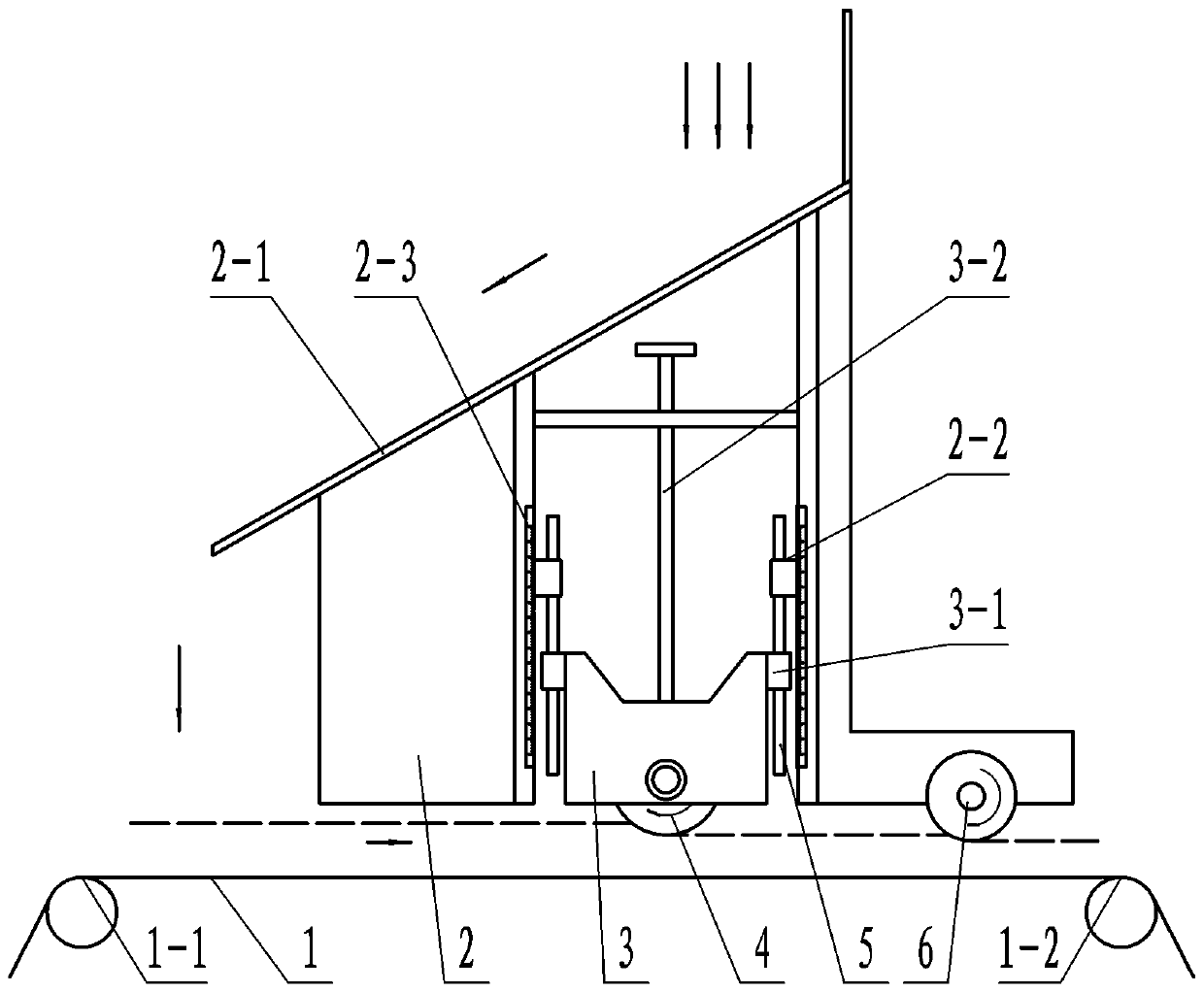

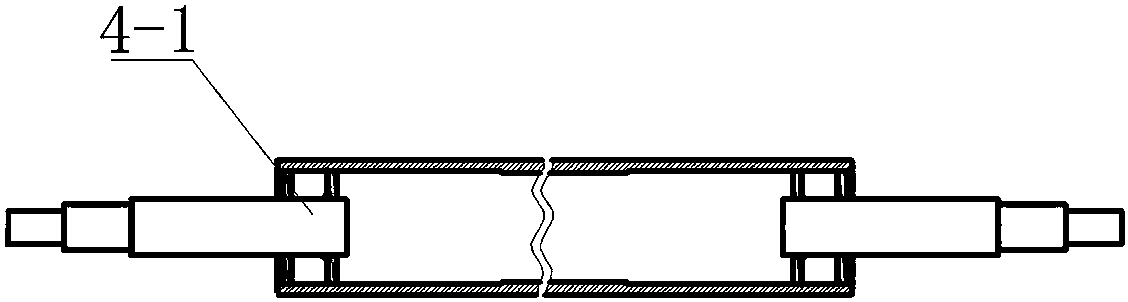

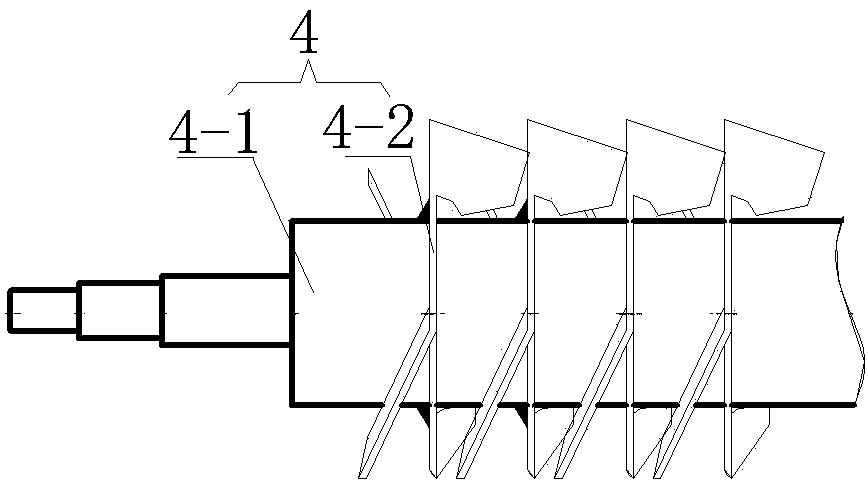

[0017] Such as figure 1 The shown sweeping roller device of the paving machine includes a paving mesh belt 1 provided with a feed end 1-1 and a discharge end 1-2, and a sweeping roller 6 is arranged above the paving mesh belt 1, and the sweeping roller 6 passes through the bearing The seat is installed on the frame 2. In this embodiment, a leveling roller 4 is provided on the frame 2 near the feed end side of the paving mesh belt 1 of the leveling roller 6, and the leveling roller 4 is placed on the frame above the leveling roller 4. There is a guide plate 2-1 obliquely, and the lower end of the guide plate 2-1 is close to the feed end 1-1 of the pavement mesh belt 1; The bearing carriage 3 is provided with two vertical guide rods 5 on both sides respectively, the vertical guide rods 5 are installed in the sliding sleeve 3-1, and the two sliding sleeves 3-1 are welded on both sides of the linear bearing carriage; The linear bearing carriage 3 is slidingly connected with the c...

Embodiment 2

[0019] The bending angle a between the opposite plow blades is 130 degrees, and other features are the same as in Embodiment 1.

Embodiment 3

[0021] The bending angle a between the opposite plow blades is 140°, and other features are the same as in Embodiment 1.

[0022] When working, since there is a leveling roller at the feeding front end of the leveling roller, the fiber blank that falls to the feeding end of the pavement mesh belt through the guide plate first passes through the leveling roller, and the leveling roller can smoothly and quickly move the excess coarse fibers to a uniform direction. The flattened fiber slab passes through the sweeping roller again, and the transverse density distribution and thickness of the produced MDF are more stable, and the flatness of the MDF during the paving process does not exceed Poor, the lateral density deviation and thickness deviation of the quality of the finished MDF board are small; the average density deviation of the MDF produced by statistics is -0.83 and +0.78, and the maximum deviation is 1.13, which achieves higher accuracy; while increasing dial The average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com