A kind of preparation method of n-alkylacrylamide

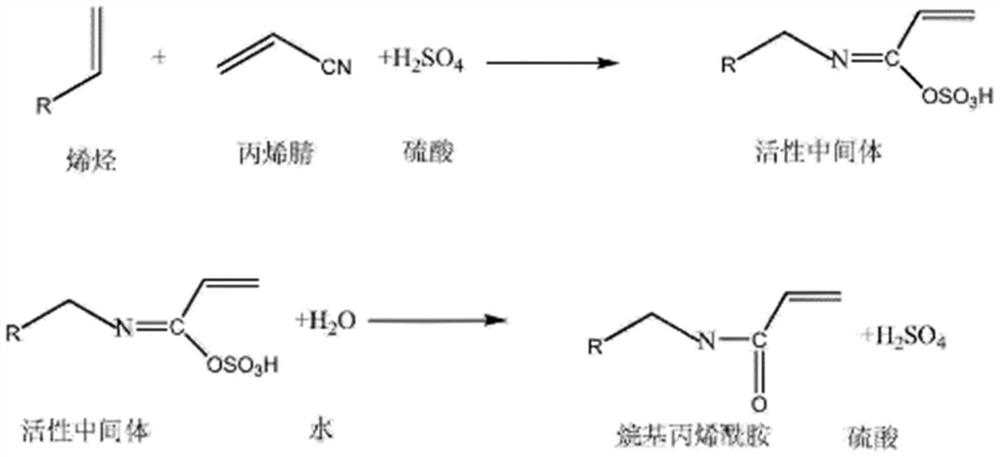

A technology of alkyl acrylamide and acrylonitrile, which is applied in the preparation of carboxylic acid amide, organic compound, sulfuric acid ester, etc. It can solve the problems of high cost and low recycling rate of waste liquid, so as to reduce the treatment cost and speed up the production process. The effect of reaction speed and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to the preparation method of N-alkylacrylamide described in the present invention, comprising the following steps:

[0040] 1) According to the ratio of n (acrylonitrile): n (α-olefin): n (concentrated sulfuric acid) = 1:0.95:1, add 130.7g of concentrated sulfuric acid with a concentration of 75% to the equipment equipped with a condenser, thermometer, and agitator In the reactor, the temperature of the system was lowered to 5°C with an ice-water bath, and 53 grams of acrylonitrile and 159.9 grams of 1-dodecene were slowly added dropwise in sequence. During the dropping process, the reaction temperature did not exceed 8°C. , the temperature of the system was raised to 40°C, and the stirring reaction was continued for 3.5h; the reaction was completed, and an intermediate was obtained;

[0041] 2) Add 17.1 grams of deionized water to the monomer, stir evenly, let stand, and separate layers to obtain an upper layer solution and a lower layer solutio...

Embodiment 2

[0044] This embodiment relates to the preparation method of N-alkylacrylamide described in the present invention, comprising the following steps:

[0045]1) According to the ratio of n (acrylonitrile): n (α-olefin): n (concentrated sulfuric acid) = 1:1:1.2, add 147g of concentrated sulfuric acid with a concentration of 80% into a container equipped with a condenser, a thermometer and a stirrer. In the reactor, the temperature of the system was lowered to 5°C in an ice-water bath, and 53 grams of acrylonitrile and 196 grams of 1-tetradecene were slowly added dropwise in sequence. During the dropwise addition, the reaction temperature did not exceed 8°C. After the dropwise addition, the system The temperature was raised to 40°C, and the stirring reaction was continued for 3.5 hours; the reaction was completed, and the monomer was obtained;

[0046] 2) Add 18 grams of deionized water to the intermediate, stir evenly, leave standstill, and separate layers to obtain an upper layer ...

Embodiment 3

[0049] This embodiment relates to the preparation method of N-alkylacrylamide described in the present invention, comprising the following steps:

[0050] 1) According to the ratio of n (acrylonitrile): n (α-olefin): n (concentrated sulfuric acid) = 1: 1.1: 1.2, add 138.2 g of concentrated sulfuric acid with a concentration of 85% into a condenser, thermometer, and agitator In the reactor, the temperature of the system was lowered to 5°C with an ice-water bath, and 53 grams of acrylonitrile and 246.4 grams of 1-hexadecene were slowly added dropwise in sequence. During the dropwise addition, the reaction temperature did not exceed 8°C. After the dropwise addition, The temperature of the system was raised to 50°C, and the stirring reaction was continued for 6 hours; after the reaction was completed, an intermediate was obtained;

[0051] 2) Add 18 grams of deionized water to the intermediate, stir evenly, leave standstill, and separate layers to obtain an upper layer solution an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com