Special modifier for manufactured sand cement concrete

A technology of cement concrete and modifier, applied in the field of construction, can solve the problems of lack of river sand resources, increase in cost, increase in dosage, etc., and achieve the effects of obvious reduction in viscosity, no loss in slump, and good dispersing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

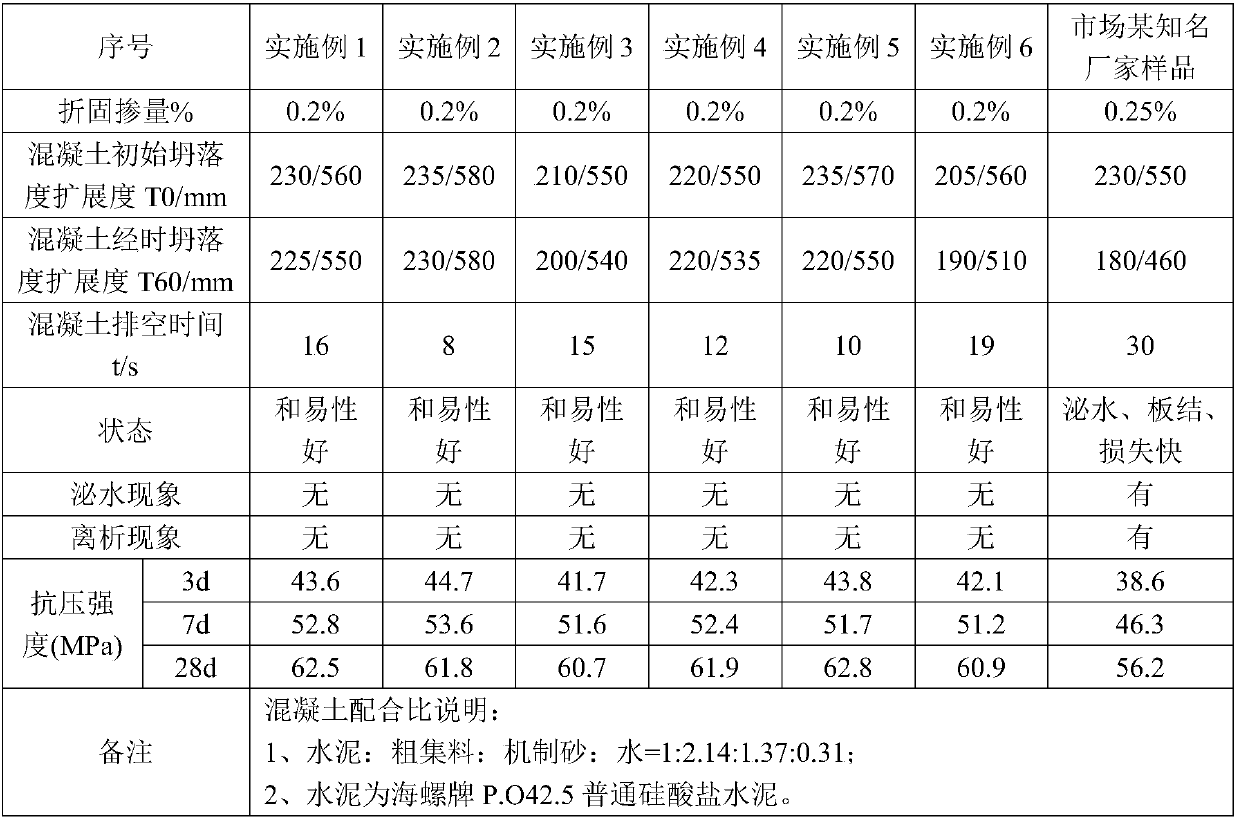

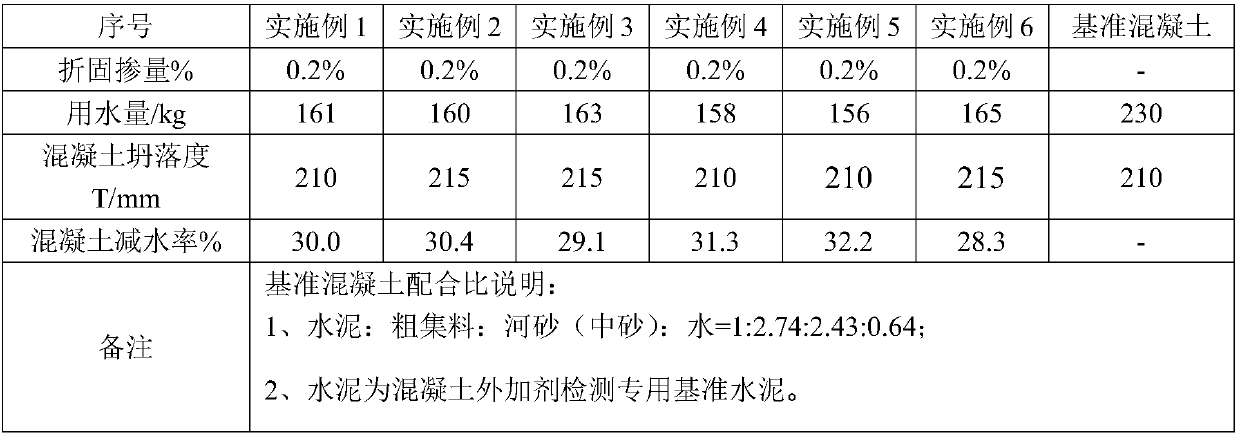

Examples

Embodiment 1

[0020] Preparation of special modifier for machine-made sand cement concrete

[0021] Add 4kg of methacrylic acid, 10kg of polyethylene glycol monoacrylate, and 6kg of sodium methacrylic sulfonate into water to prepare a mixed aqueous solution with a concentration of 25%, and add 0.5kg of 1.5% supernatant to the mixed aqueous solution. Oxidize the tert-butyl benzoate solution, then react at a temperature of 70°C for 8 hours to obtain a reaction solution, and finally adjust the pH value of the reaction solution to 7 with 10% NaOH aqueous solution to obtain the special modifier for machine-made sand cement concrete .

Embodiment 2

[0023] Preparation of special modifier for machine-made sand cement concrete

[0024] Add 7kg of methacrylic acid, 18kg of polyethylene glycol monoacrylate, and 11kg of sodium methacryl sulfonate into water to prepare a mixed aqueous solution with a concentration of 26%, and add 1.3kg of 1.5% supernatant to the mixed aqueous solution. Oxidize the tert-butyl benzoate solution, then react at 75°C for 7 hours to obtain a reaction solution, and finally adjust the pH value of the reaction solution to 7.5 with 10% NaOH aqueous solution to obtain the special modifier for machine-made sand cement concrete .

Embodiment 3

[0026] Preparation of special modifier for machine-made sand cement concrete

[0027] Add 10kg of methacrylic acid, 26kg of polyethylene glycol monoacrylate, and 15kg of sodium methacrylate into water to prepare a mixed aqueous solution with a concentration of 28%, and add 2kg of peroxide with a concentration of 1.5% to the mixed aqueous solution. The tert-butyl benzoate solution was then reacted at 80° C. for 6 hours to obtain a reaction solution, and finally the pH value of the reaction solution was adjusted to 8 with 10% NaOH aqueous solution to obtain the special modifier for machine-made sand cement concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com