Preparation method of matting agent titanium dioxide suspension for polymer

A technology of titanium dioxide and suspension, which is applied in the field of preparation of titanium dioxide suspension as a matting agent for polymers, which can solve the problems of high energy consumption and low grinding efficiency, and achieve the effect of strong dispersion and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

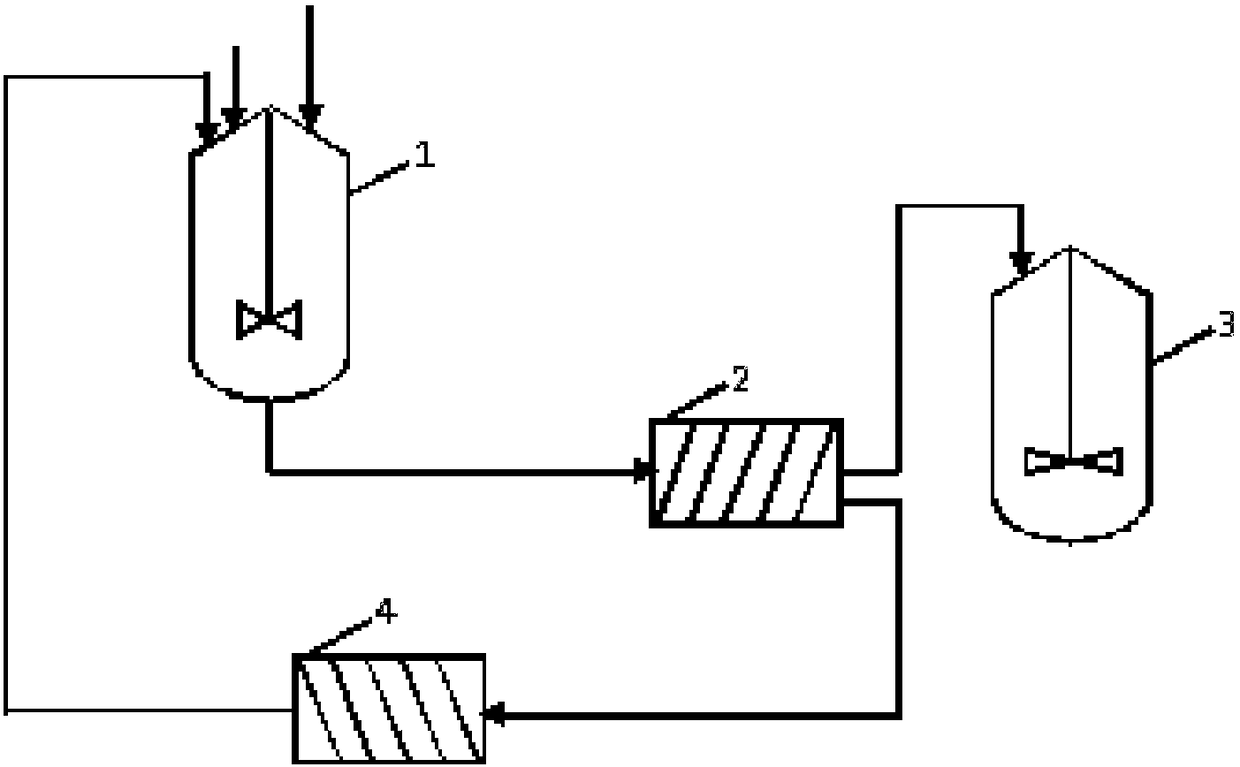

[0047] Such as figure 1 As shown, titanium dioxide and water containing 45wt% caprolactam are dissolved in the mixer 1 to prepare a slurry containing about 12wt% or 22wt% of titanium dioxide. The median particle size is 0.589μm after testing. After the centrifuge 2 is processed, the small particle size titanium dioxide liquid Enter the blending tank 3, after the concentration is adjusted to 12% or 22%, it is sent to the polymerization device for use. After centrifugation, the slurry containing large particles of titanium dioxide (median particle size is 0.632μm) enters the ultrasonic processor 4 (ultrasonic oscillator) with frequency The median size of titanium dioxide after 10 min treatment at 53 KHz frequency was 0.537μm, and the slurry hue remained unchanged before and after the slurry was sent back to the tank for reuse.

Embodiment 2

[0049] The matting agent titanium dioxide powder is mixed with the aqueous solution containing 75wt% hexamethylene diamine adipate to form a 10wt% or 20wt% slurry. After centrifuge treatment, the small particle size titanium dioxide liquid enters the fine blending tank, and the concentration is adjusted to 10 wt. % Or 20 wt% and then sent to the polymerization device. After centrifugation, the slurry containing large particles of titanium dioxide enters the ultrasonic disperser and is treated at a frequency of 20KHz for 15 minutes, and then the slurry is returned to the preparation tank for reuse. The median size of titanium dioxide before and after treatment with ultrasonic disperser was tested to be 0.593μm and 0.564μm, and the color of the slurry remained unchanged before and after treatment.

Embodiment 3

[0051] The matting agent titanium dioxide powder is mixed with hexanediol to form a 50wt% slurry. After centrifuge treatment, the small particle size titanium dioxide liquid enters the fine mixing tank, and the concentration is adjusted to 10 wt% to be sent to the polymerization device for use. After centrifugal treatment, it contains large particles of titanium dioxide The slurry enters the ultrasonic disperser and is treated with a frequency of 20KHz for 15 minutes, and then the slurry is returned to the preparation tank for reuse. The median diameter of titanium dioxide before and after treatment with ultrasonic disperser was tested to be 0.509μm, and the color of the slurry was unchanged before and after treatment with 0.433μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com