Low-water-absorption pearl wool and preparation method thereof

A technology of low water absorption and pearl cotton, which is applied in the field of polymer materials, can solve the problems of low water absorption and other problems, and achieve the effect of strong dispersion ability and superior physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

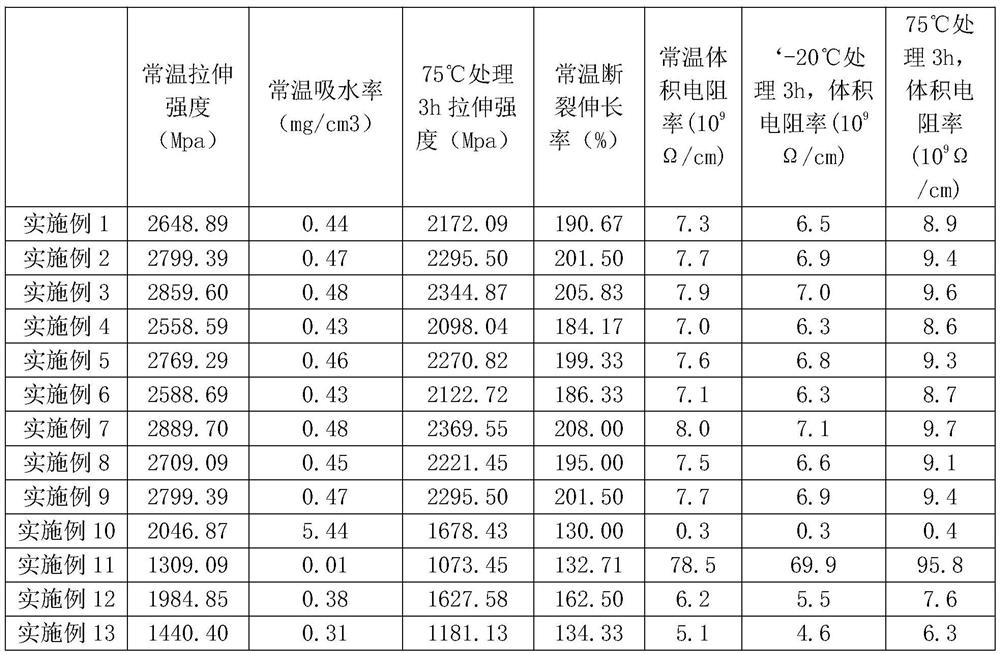

Examples

Embodiment 1

[0030] A kind of low water absorption pearl cotton, raw material comprises:

[0031] Low-density polyethylene 9000g;

[0032] Polypropylene-polyethylene polymer particle A 3000g;

[0033] Graft cotton fiber 1400g;

[0034] Silane coupling agent 500g;

[0035] Baking soda 200g;

[0036] Sodium lignosulfonate 1500g;

[0037] Molecularly distilled monoglyceride 600g.

[0038] Preparation of pearl cotton with low water absorption: 1) Add low-density polyethylene, silane coupling agent, molecularly distilled monoglyceride and grafted cotton fiber into the reaction kettle, stir evenly and raise the temperature to 116°C-125°C, and maintain it for 5-9min. 2) Add polypropylene-polyethylene polymer particles A, sodium lignosulfonate and baking soda, stir evenly and continue to heat up to 128-132°C, feed into foaming machine for foaming, heat preservation and pressure foaming treatment to maintain 5- 8min, then extrude from the mould; 3) cooling molding, obtains the pearl cotton wi...

Embodiment 2

[0040] A kind of low water absorption pearl cotton, raw material comprises:

[0041] Low-density polyethylene 9800g;

[0042] Polypropylene-polyethylene polymer particle A 4000g;

[0043] Graft cotton fiber 1200g;

[0044] Silane coupling agent 400g;

[0045] Baking soda 300g;

[0046] Sodium lignosulfonate 1200g;

[0047] Molecularly distilled monoglyceride 300g.

[0048] Preparation of pearl cotton with low water absorption: 1) Add low-density polyethylene, silane coupling agent, molecularly distilled monoglyceride and grafted cotton fiber into the reaction kettle, stir evenly and raise the temperature to 116°C-125°C, and maintain it for 5-9min. 2) Add polypropylene-polyethylene polymer particles A, sodium lignosulfonate and baking soda, stir evenly and continue to heat up to 128-132°C, feed into foaming machine for foaming, heat preservation and pressure foaming treatment to maintain 5- 8min, then extrude from the mould; 3) cooling molding, obtains the pearl cotton wi...

Embodiment 3

[0050] A kind of low water absorption pearl cotton, raw material comprises:

[0051] Low-density polyethylene 9200g;

[0052] Polypropylene-polyethylene polymer particles A 3200g;

[0053] Graft cotton fiber 1300g;

[0054] Silane coupling agent 200g;

[0055] Baking soda 400g;

[0056] Sodium lignosulfonate 1000g;

[0057] Molecularly distilled monoglyceride 500g.

[0058]Preparation of pearl cotton with low water absorption: 1) Add low-density polyethylene, silane coupling agent, molecularly distilled monoglyceride and grafted cotton fiber into the reaction kettle, stir evenly and raise the temperature to 116°C-125°C, and maintain it for 5-9min. 2) Add polypropylene-polyethylene polymer particles A, sodium lignosulfonate and baking soda, stir evenly and continue to heat up to 128-132°C, feed into foaming machine for foaming, heat preservation and pressure foaming treatment to maintain 5- 8min, then extrude from the mould; 3) cooling molding, obtain the pearl cotton wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com