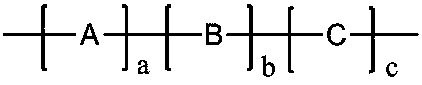

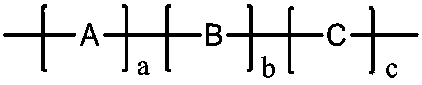

Multi-cation mud-resisting type polycarboxylic acid water reducer and preparation method thereof

A multi-cation, anti-mud type technology, applied in the field of concrete admixture, can solve the problems of poor use effect and large adsorption of polycarboxylate superplasticizer, and achieve the effect of difficult desorption, inhibition of adsorption, and high positive charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example provides a polycationic anti-mud type polycarboxylate superplasticizer and its preparation method:

[0037] The first step: preparation of unsaturated anti-mud type monomer C solution

[0038] Put 174 parts of hydroxyethyl acrylate into the reactor, and add dropwise a hydrochloric acid solution containing 142 parts of tetraethylenepentamine at 30°C for 1 hour to obtain the unsaturated mud-resistant monomer C solution.

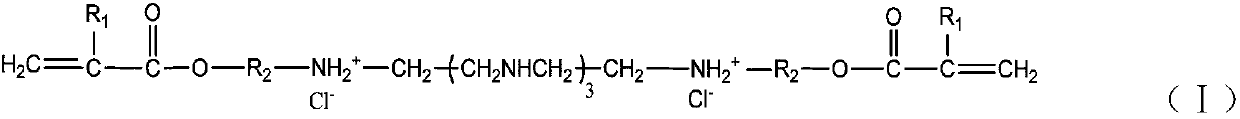

[0039] The general formula of the unsaturated anti-mud type monomer C is:

[0040]

[0041] where R 1 for H, R 2 for CH 2 CH 2 .

[0042] The second step: preparation of polycation anti-mud type polycarboxylate superplasticizer

[0043] Put 2400 parts of polyether macromonomer TPEG (prenyl alcohol polyoxyethylene ether, molecular weight 2400) in the reactor, add water to dissolve; 144 parts of acrylic acid and the prepared unsaturated anti-mud type monomer C solution, mix and dissolve , recorded as X component; 16 parts of hydrogen...

Embodiment 2

[0045] This example provides a polycationic anti-mud type polycarboxylate superplasticizer and its preparation method:

[0046] The first step: preparation of unsaturated anti-mud type monomer C solution

[0047] Put 65 parts of hydroxypropyl acrylate into the reactor, and add dropwise a hydrochloric acid solution containing 94 parts of tetraethylenepentamine at 60°C for 2 hours to obtain the unsaturated mud-resistant monomer C solution.

[0048] The general formula of the unsaturated anti-mud type monomer C is:

[0049]

[0050] where R 1 for H, R 2 for (CH 3 )CHCH 2 .

[0051] The second step: preparation of polycation anti-mud type polycarboxylate superplasticizer

[0052] Put 2400 parts of polyether macromonomer HPEG (methallyl polyoxyethylene ether, molecular weight 2400) in the reactor, add water to dissolve; 288 parts of acrylic acid and the prepared unsaturated anti-mud type monomer C solution, mix Dissolved, recorded as X component; 18 parts of hydrogen pero...

Embodiment 3

[0054] This example provides a polycationic anti-mud type polycarboxylate superplasticizer and its preparation method:

[0055] The first step: preparation of unsaturated anti-mud type monomer C solution

[0056] Put 97.5 parts of hydroxyethyl methacrylate into the reactor, and add dropwise a hydrochloric acid solution containing 106.5 parts of tetraethylenepentamine at 45°C for 1.5 hours to obtain the unsaturated mud-resistant monomer C solution.

[0057] The general formula of the unsaturated anti-mud type monomer C is:

[0058]

[0059] where R 1 for CH 3 , R 2 for CH 2 CH 2 .

[0060] The second step: preparation of polycation anti-mud type polycarboxylate superplasticizer

[0061] Put 2400 parts of polyether macromonomer VPEG (4-hydroxybutyl vinyl polyoxyethylene ether, molecular weight 2400) in the reactor, add water to dissolve; 216 parts of acrylic acid and the prepared unsaturated anti-mud type monomer C solution , mix and dissolve, and record it as compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com