Method for predicting eutectic temperatures of nano Ag-Cu alloy systems in different sizes

A prediction method and technology of eutectic temperature, applied in nanotechnology, chemical property prediction, metal processing equipment, etc., can solve the problems of no nano-alloy related experimental data, etc., achieve strong reliability, ensure accuracy, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

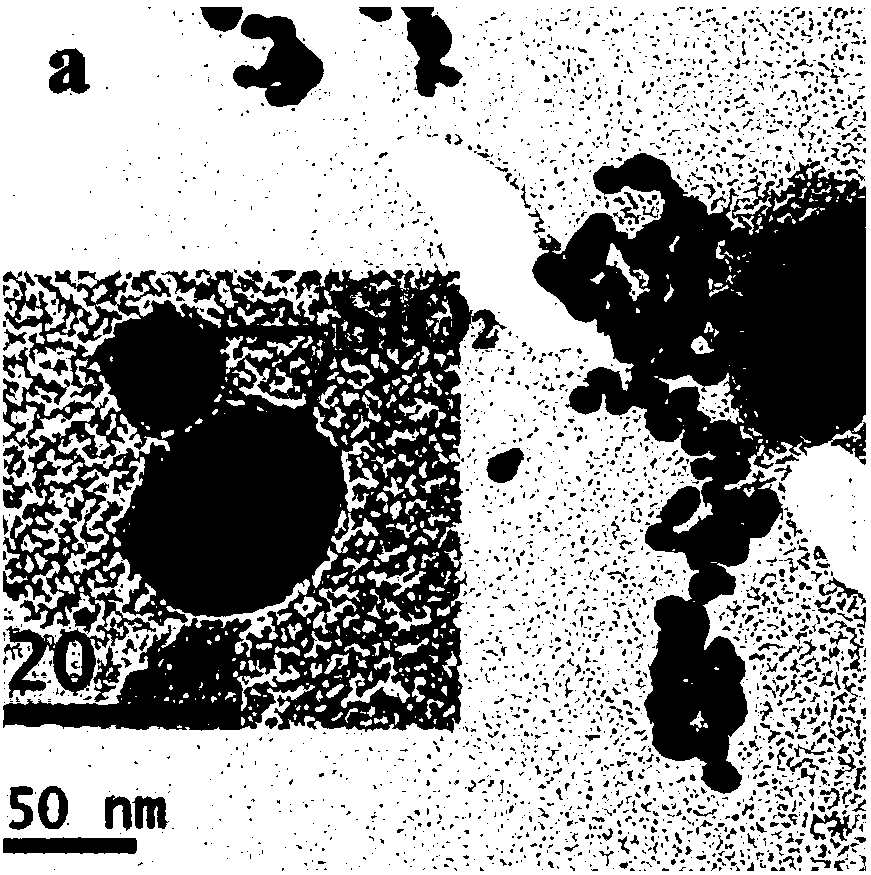

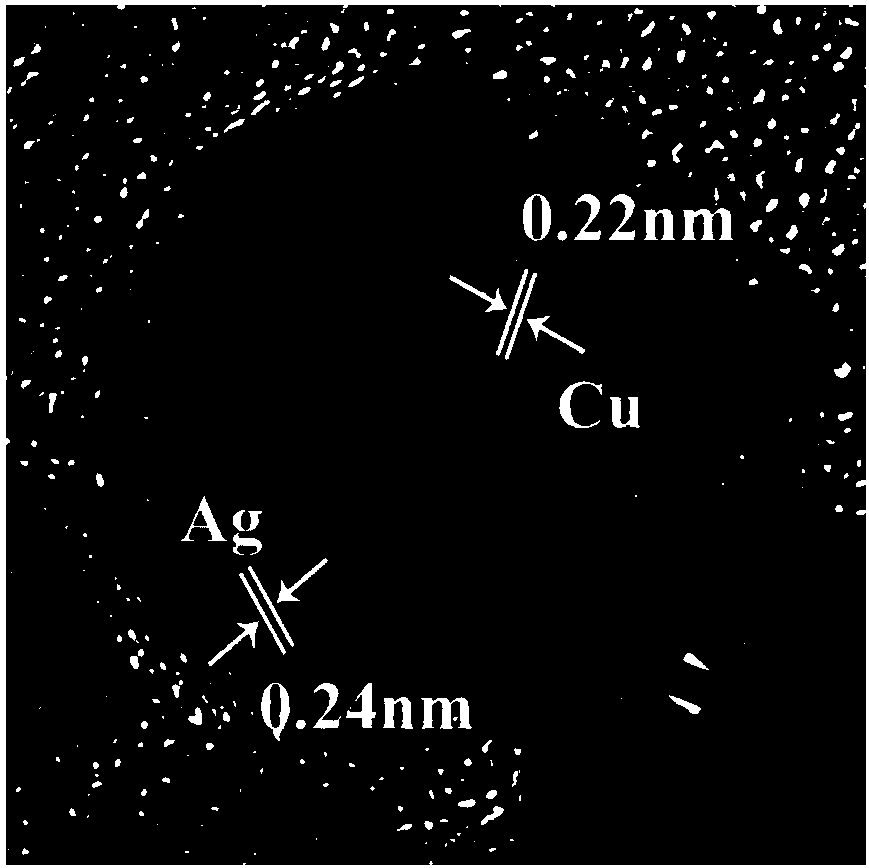

[0038] The concrete operating steps of the eutectic temperature experiment measuring method of nanometer Ag8Cu2 alloy of the present invention are as follows:

[0039] Step (1), configure AgNO of 0.01mol / L 3 solution and 0.01mol / L CuSO 4Solution, the prepared solution is mixed according to the proportion of Ag8Cu2 ions, so that 50ml solution is obtained.

[0040] In step (2), the above solution is diluted to 97ml with deionized water, and 3ml of sodium citrate with a mass fraction of 1% is added dropwise.

[0041] In step (3), the prepared solution was stirred and heated to boiling under an argon protective atmosphere, put into water to cool to room temperature, poured 3ml of NaBH4 with a concentration of 1mmol / L at one time, and stirred rapidly until the color was uniform.

[0042] Step (4), leave the solution for one hour, add 0.1 ml of 3-aminopropanetrihydrosilane with a concentration of 1 mmol / L, stir evenly, and leave it for another 15 minutes.

[0043] Step (5), stir ...

Embodiment 2

[0050] The concrete operating steps of the eutectic temperature CALPHAD prediction method of nanometer Ag7Cu3 alloy of the present invention are as follows:

[0051] Step (1), configure AgNO of 0.01mol / L 3 solution and 0.01mol / L CuSO 4 Solution, the prepared solution is mixed according to the ratio of Ag7Cu3 ions, so that 50ml solution is obtained.

[0052] In step (2), the above solution is diluted to 97ml with deionized water, and 3ml of sodium citrate with a mass fraction of 1% is added dropwise.

[0053] In step (3), the prepared solution was stirred and heated to boiling under an argon protective atmosphere, put into water to cool to room temperature, poured 3ml of NaBH4 with a concentration of 1mmol / L at one time, and stirred rapidly until the color was uniform.

[0054] Step (4), leave the solution for one hour, add 0.1 ml of 3-aminopropanetrihydrosilane with a concentration of 1 mmol / L, stir evenly, and leave it for another 15 minutes.

[0055] Step (5), stir slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

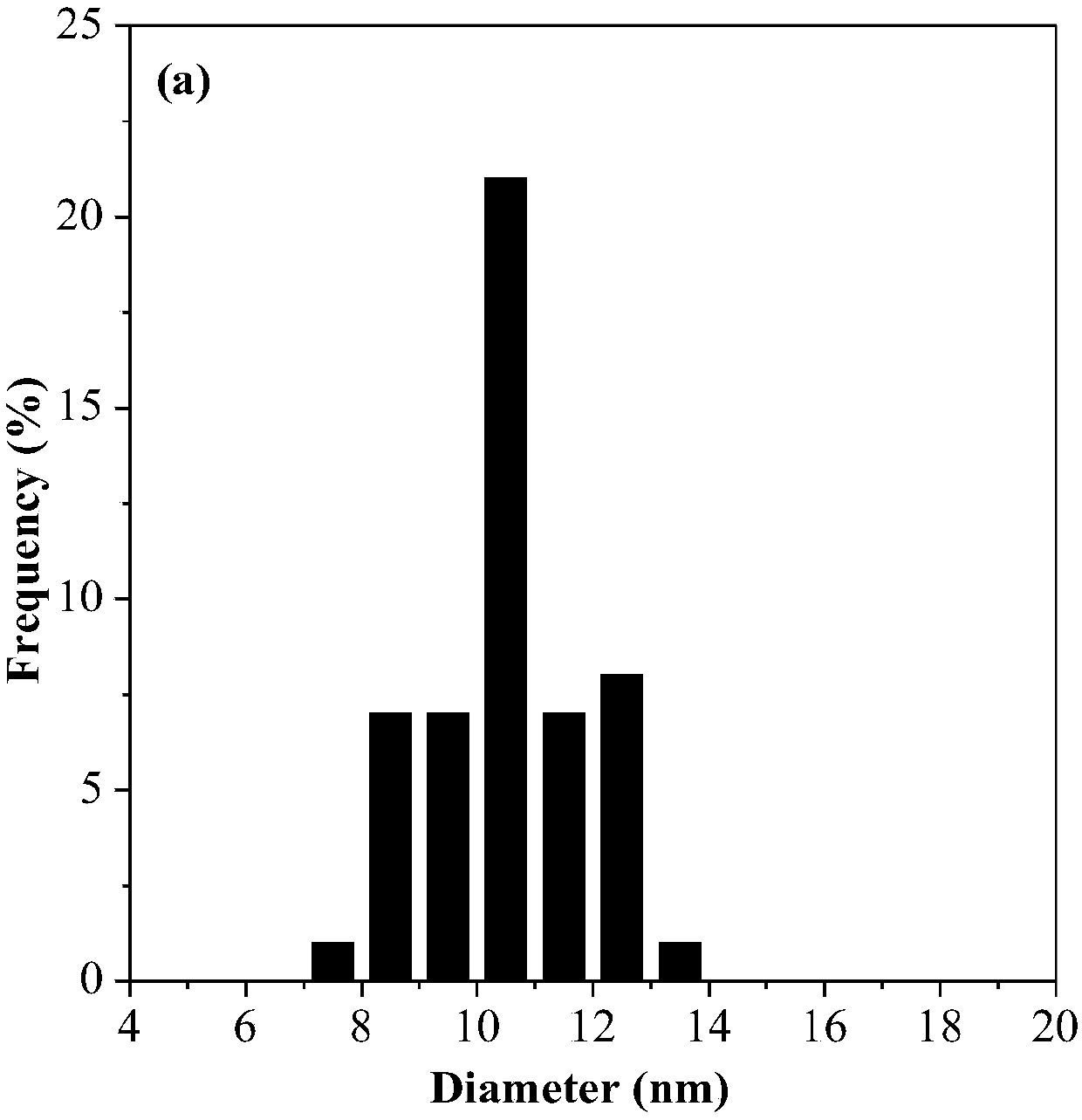

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com