Processing technology of lateolabrax japonicus meat floss

A processing technology, the technology of perch floss, applied in the field of seafood processing, can solve the problems of hard texture, high salt content, and small applicable groups of fish, and achieve the effects of easy absorption, good taste and delicious meat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

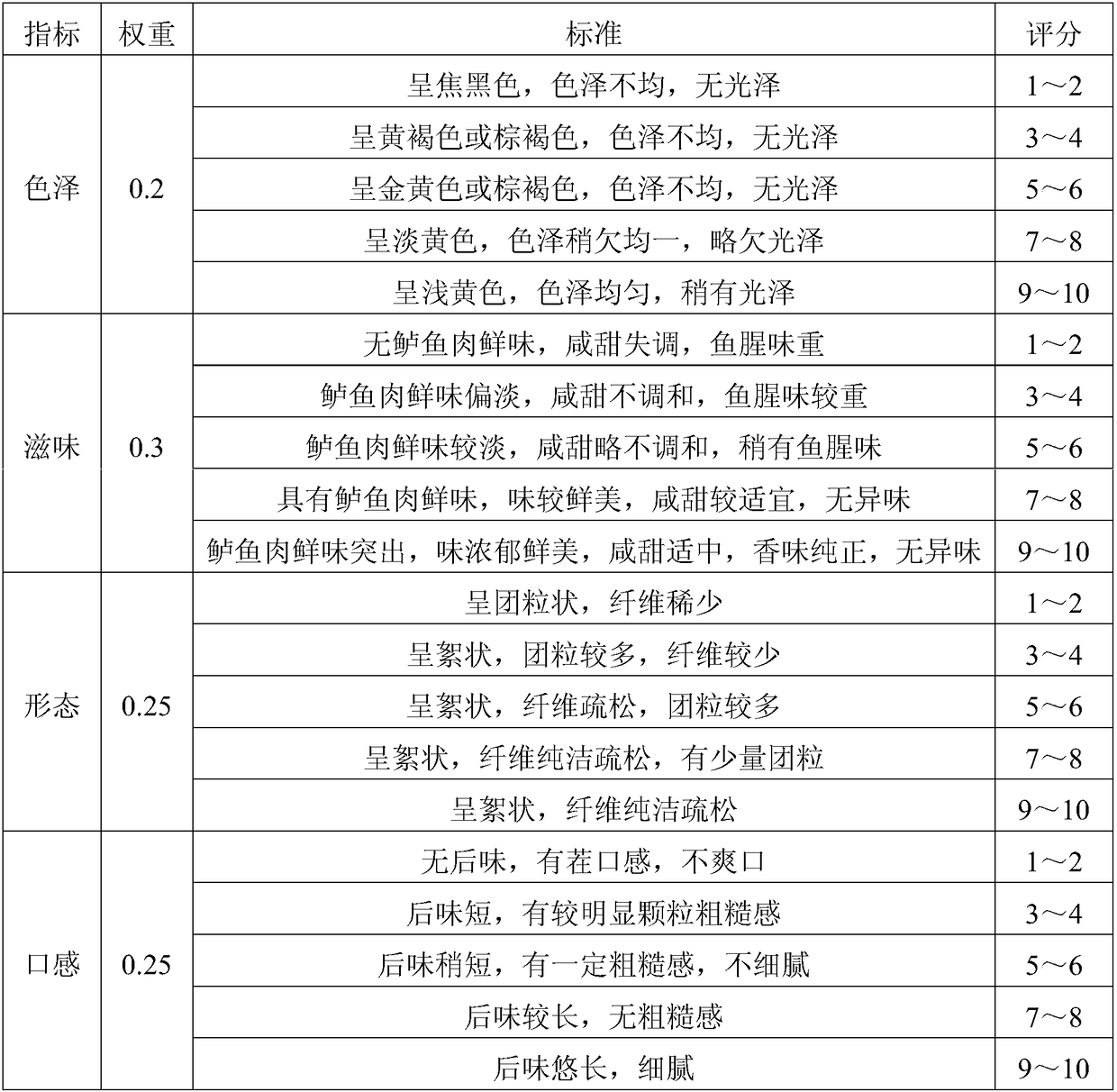

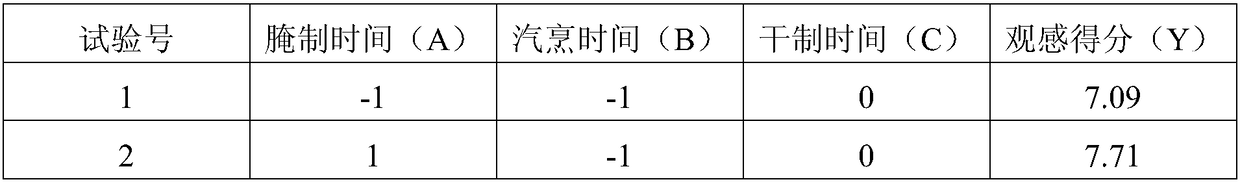

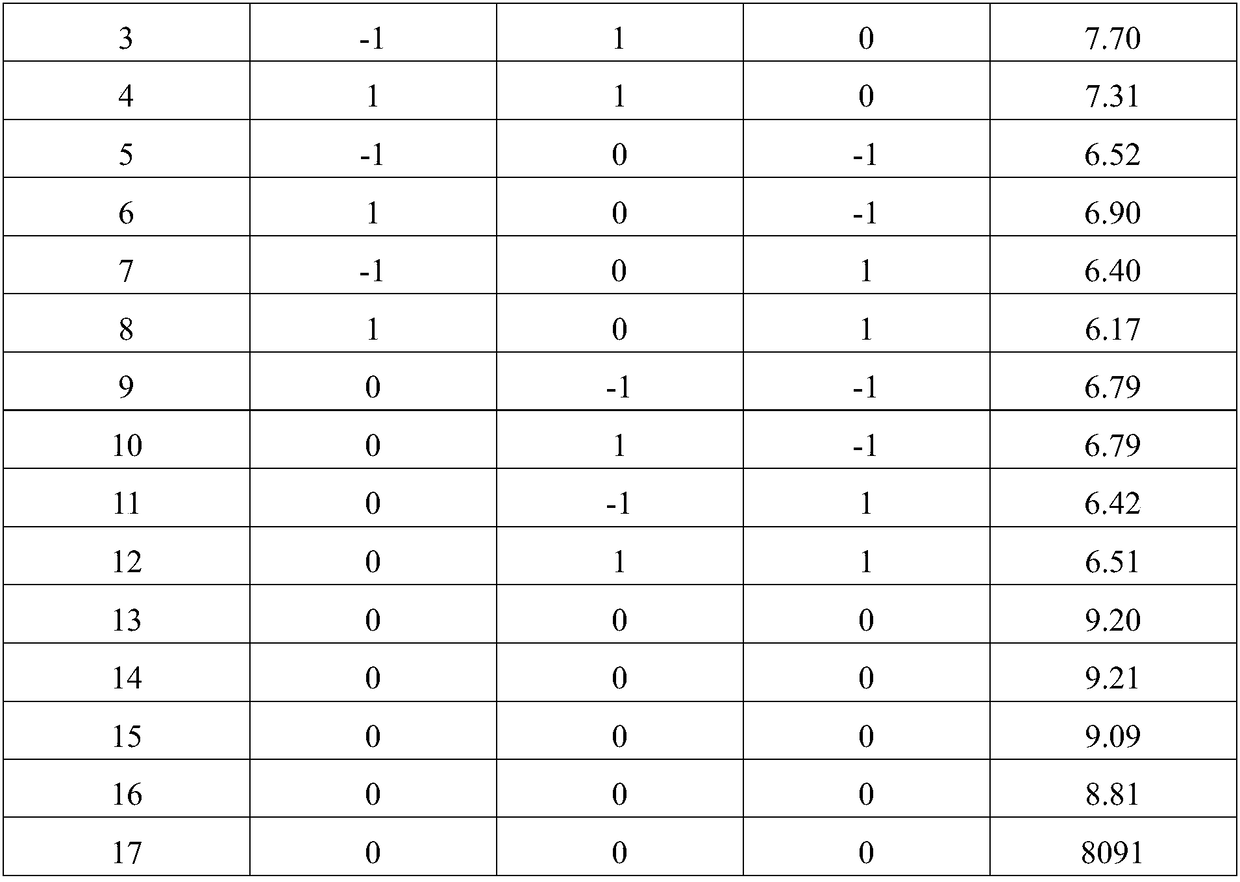

Method used

Image

Examples

Embodiment 1

[0018] The processing technology of seven-star perch floss comprises the following steps:

[0019] (1) Raw material pretreatment: select fresh seven-star perch, after cleaning, cut into blocks of uniform size, and scratch on the surface of the block fish blocks, and set aside;

[0020] (2) Seasoning and pickling: edible salt and sucrose are mixed into seasoning, added to the fish block, and the volume fraction of the seasoning accounts for 30% of the fish block, and marinated for 0.5h;

[0021] (3) Steam cooking: after marinating, put the fish pieces in a boiling steamer and cook them with the side of the fish skin facing up, cover the surface of the fish pieces with green onions, ginger, and garlic for cooking Boil, steam for 16 minutes;

[0022] (4) Stem removal and drying: After steam cooking, remove the skin of the fish pieces, remove the fish bones, and tear the fish meat into single-layer sheets along the texture of the fish meat, and then dry them in an oven at 73°C 2...

Embodiment 2

[0025] The processing technology of seven-star perch floss comprises the following steps:

[0026] (1) Raw material pretreatment: select fresh seven-star perch, after cleaning, cut into blocks of uniform size, and scratch on the surface of the block fish blocks, and set aside;

[0027] (2) Seasoning and marinating: edible salt and sucrose are mixed into seasoning, added to the fish block, and the seasoning accounts for 30% of the volume fraction of the fish block, and marinated for 1 hour;

[0028] (3) Steam cooking: after marinating, put the fish pieces in a boiling steamer and cook them with the side of the fish skin facing up, cover the surface of the fish pieces with green onions, ginger, and garlic for cooking Boil and steam for 18 minutes;

[0029] (4) Stem removal and drying: After steam cooking, remove the skin of the fish pieces, remove the fish bones, and tear the fish meat into single-layer sheets along the texture of the fish meat, and then dry them in an oven at ...

Embodiment 3

[0032] The processing technology of seven-star perch floss comprises the following steps:

[0033] (1) Raw material pretreatment: select fresh seven-star perch, after cleaning, cut into blocks of uniform size, and scratch on the surface of the block fish blocks, and set aside;

[0034] (2) Seasoning and pickling: edible salt and sucrose are mixed into seasoning, added to the fish block, and the volume fraction of the seasoning accounts for 30% of the fish block, and marinated for 1.5h;

[0035] (3) Steam cooking: after marinating, put the fish pieces in a boiling steamer and cook them with the side of the fish skin facing up, cover the surface of the fish pieces with green onions, ginger, and garlic for cooking Boil and steam for 20 minutes;

[0036] (4) Stem removal and drying: After steam cooking, remove the skin of the fish pieces, remove the fish bones, and tear the fish meat into single-layer sheets along the texture of the fish meat, and then dry them in an oven at 73°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com