Aluminophosphate cement-based foam concrete material resistant to sea fog erosion

A technology of foam concrete and aluminum phosphate, which is applied in the field of building materials, can solve the problems of easy damage and amazing damage speed, and achieve the effect of optimized pore structure, excellent performance and strong resistance to chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

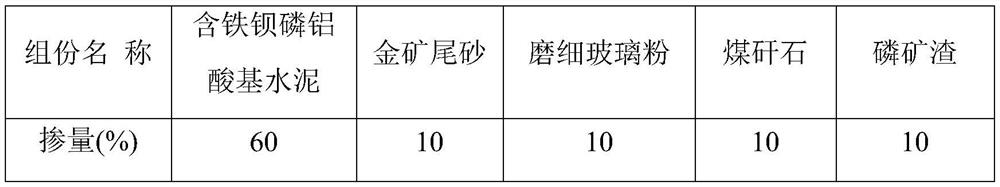

Embodiment 1

[0013] Mixed dry powder composition weight percent:

[0014]

[0015] The foaming agent added is 3% of the dry powder mass, the coagulation regulator is added 0.1% of the dry powder mass, the foam stabilizer is added 0.01% of the dry powder mass, and the water-material ratio is 0.75. Blocks with a thickness of 100 mm were made, and the strength was measured after curing for 28 days in a simulated sea fog environment. And the corrosion resistance coefficient of sulfate ion was measured under the condition of only sulfate ion attack.

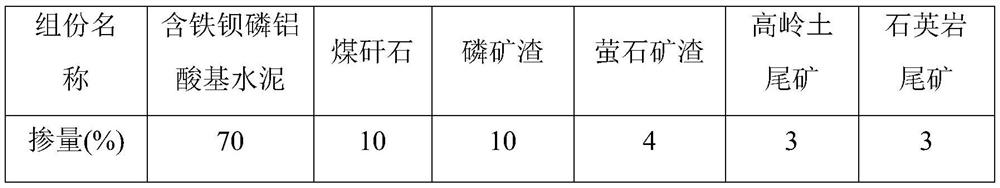

Embodiment 2

[0017] Mixed dry powder composition weight percent:

[0018]

[0019] The foaming agent added is 4.5% of the dry powder mass, the coagulation regulator is added 0.25% of the dry powder mass, the foam stabilizer is added 0.1% of the dry powder mass, and the water-material ratio is 0.5. Blocks with a thickness of 100 mm were made, and the strength was measured after curing for 28 days in a simulated sea fog environment. And the corrosion resistance coefficient of sulfate ion was measured under the condition of only sulfate ion attack.

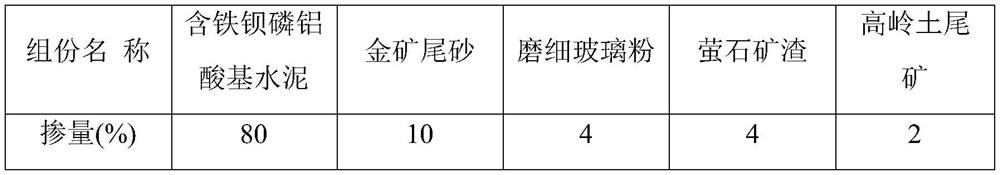

Embodiment 3

[0021] Mixed dry powder composition weight percent:

[0022]

[0023] The foaming agent added is 10% of the dry powder mass, the coagulation regulator is added 5% of the dry powder mass, the foam stabilizer is added 2% of the dry powder mass, and the water-material ratio is 0.4. Blocks with a thickness of 100 mm were made, and the strength was measured after curing for 28 days in a simulated sea fog environment. And the corrosion resistance coefficient of sulfate ion was measured under the condition of only sulfate ion attack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com