A cellulose welding rod

A cellulose and microcrystalline cellulose technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor performance of cellulose electrodes, and achieve excellent welding technology and strong arc penetration. , good effect of double-sided forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

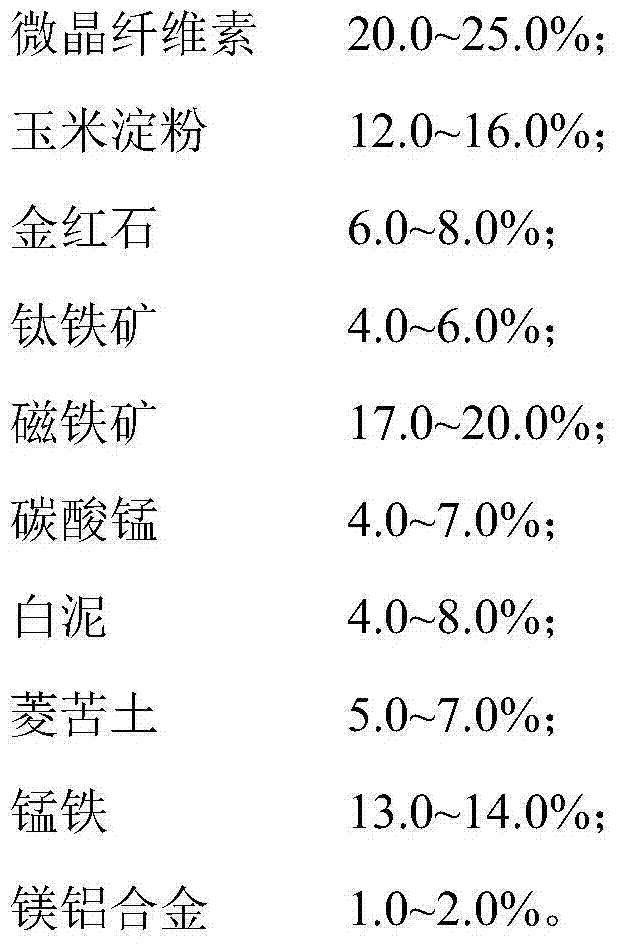

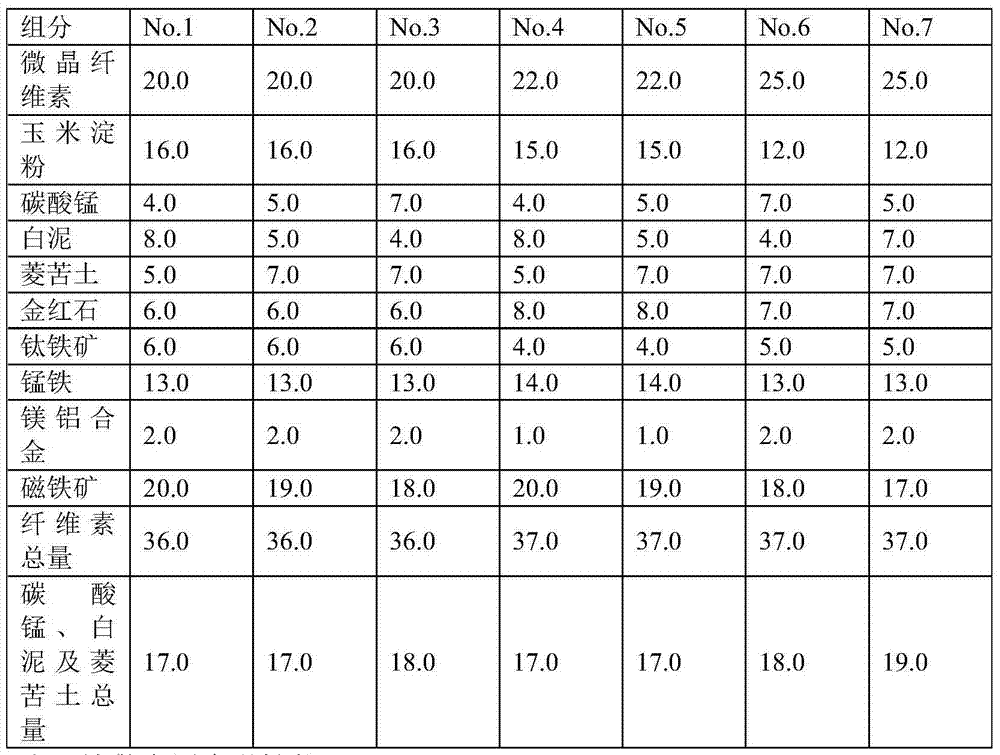

[0021] The electrode uses H08A steel core, and the components of the coating are microcrystalline cellulose, corn starch, rutile, ilmenite, magnetite, manganese carbonate, white mud, magnesite, ferromanganese and magnesium-aluminum alloy; The ratio of microcrystalline cellulose to corn starch is 1.25:1~2.1:1, and the total amount of the two (i.e. the total amount of cellulose) accounts for 36.0~37.0% of the mass percentage of the drug skin; manganese carbonate, white mud and magnesite The total amount accounts for 17.0-19.0% of the mass percentage of the drug skin.

[0022] To make welding rods, according to the ordinary acid welding rod manufacturing method, potassium sodium water glass is used as a binder, and the uniformly mixed powder is evenly pressed on the surface of the welding core to make welding rods of Φ3.2mm and Φ4.0mm.

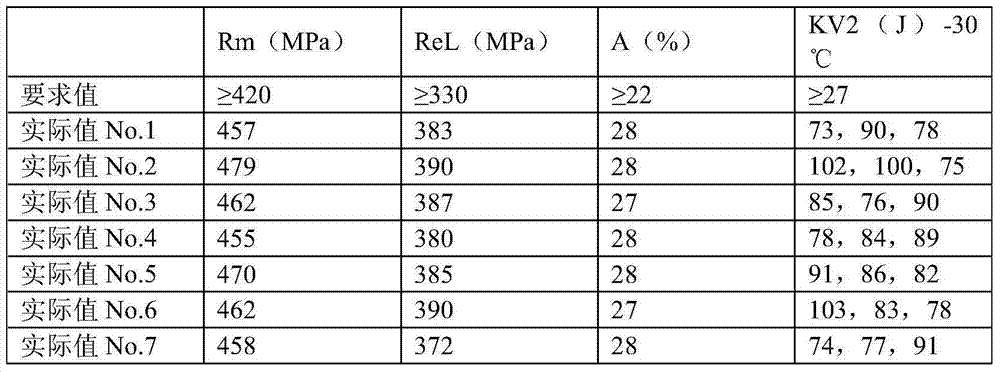

[0023] According to the above method, and the ratio of the 7 groups of coating ingredients of No.1 to No.7 in Table 1, the welding rod was prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com