A kind of alkali excited coal gangue powder geopolymer cementitious material and preparation method thereof

A technology of geopolymers and coal gangue powder, which is applied in chemical instruments and methods, cement production, water/sludge/sewage treatment, etc., can solve problems that cannot meet the special construction technology and tunneling technology of shafts, affect the progress of tunneling work, Low construction efficiency and other problems, to achieve the effect of low price, improved water absorption performance, and control of mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

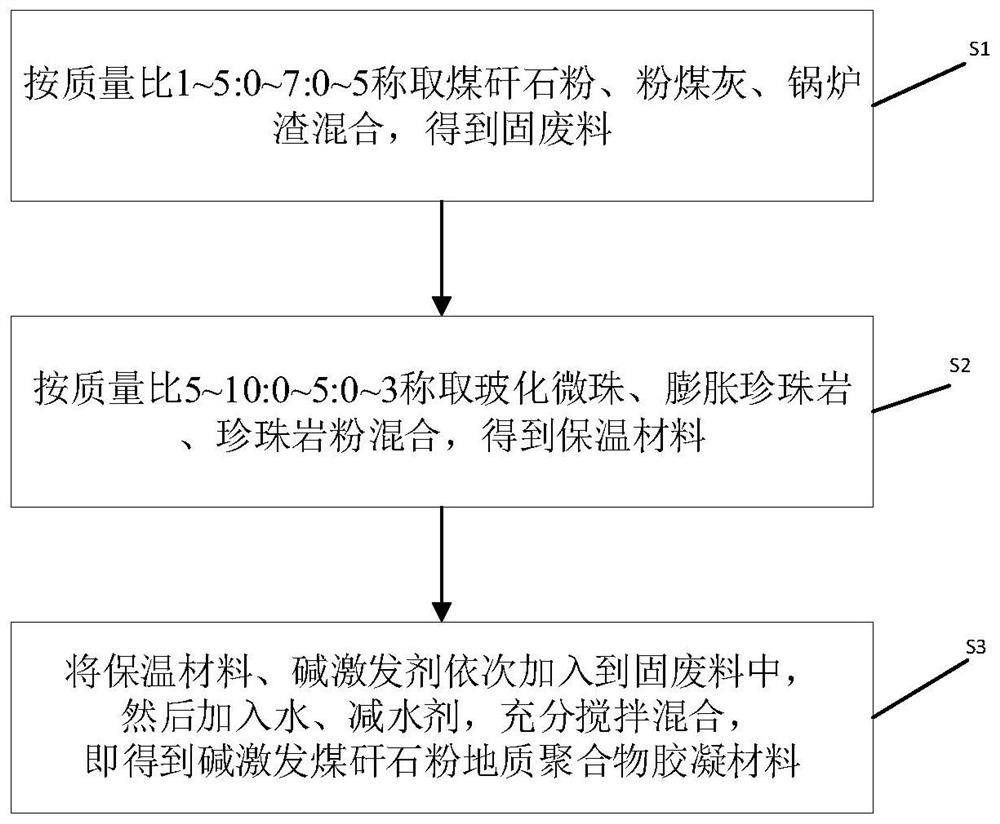

[0026] refer to figure 1 , the present invention also provides the preparation method of the above-mentioned alkali-activated coal gangue powder geopolymer cementitious material, comprising the following steps:

[0027] Step S1, weighing coal gangue powder, fly ash, and boiler slag according to the mass ratio of 1 to 5:0 to 7:0 to 5, and mixing them to obtain solid waste;

[0028] Step S2, weighing vitrified microbeads, expanded perlite, and perlite powder according to a mass ratio of 5-10:0-5:0-3 and mixing them to obtain an insulating material;

[0029] Step S3, adding thermal insulation material and alkali activator to the solid waste in sequence, then adding water and water reducer, fully stirring and mixing to obtain alkali-activated coal gangue powder geopolymer gelling material; wherein, the amount of thermal insulation material Accounting for 30% to 60% of the mass of solid waste, the amount of alkali activator accounts for 6% to 8% of the mass of solid waste, the amo...

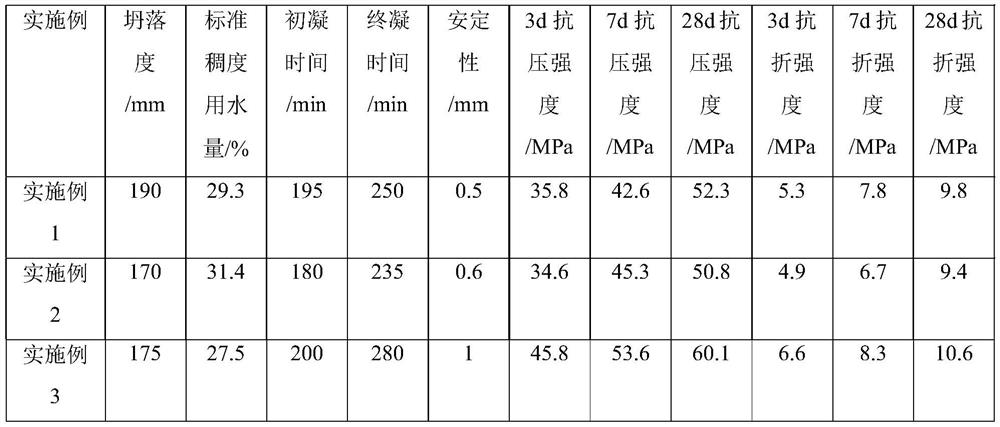

Embodiment 1

[0033] Weigh 5kg of coal gangue powder, 25kg of fly ash, and 20kg of boiler slag and add them to the mixer and stir for 1min, fully stir to obtain solid waste; weigh 16.95kg of vitrified microbeads, 3.75kg of expanded perlite, and 4.3kg of perlite powder to fully Stir and mix to obtain thermal insulation material; dissolve sodium hydroxide analytically pure in water to prepare NaOH aqueous solution, then mix with water glass to obtain alkali activator; take 25kg thermal insulation material, 3.0kg alkali activator, and add them to 50kg solid waste in turn Then add 18kg of water and 0.35kg of polycarboxylate superplasticizer, and stir for 5 minutes to fully mix to obtain the alkali-activated coal gangue powder geopolymer cementitious material.

Embodiment 2

[0035] Weigh 20kg of coal gangue powder, 25kg of fly ash, and 5kg of boiler slag and add them to the mixer and stir for 1min, fully stir to obtain solid waste; weigh 18.75kg of vitrified microbeads, 4.5kg of expanded perlite, and 5.25kg of perlite powder to fully Stir and mix to obtain the insulation material; dissolve the analytically pure sodium hydroxide in water to prepare an aqueous NaOH solution, then mix it with water glass to obtain an alkali activator; take 28.5kg of insulation material, 3.9kg of Then add 17.5kg of water and 0.4kg of polycarboxylate superplasticizer to the waste, and stir for 5 minutes to fully mix to obtain the alkali-activated coal gangue powder geopolymer gelling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com