Cellulose nanocrystal-polyethylenimine nano-compound gene carrier and preparation method thereof

A technology of polyethylenimine and nanocomposites, applied in other methods of inserting foreign genetic materials, recombinant DNA technology, etc., can solve problems such as application constraints and increased cytotoxicity, achieve good biocompatibility, reduce costs, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

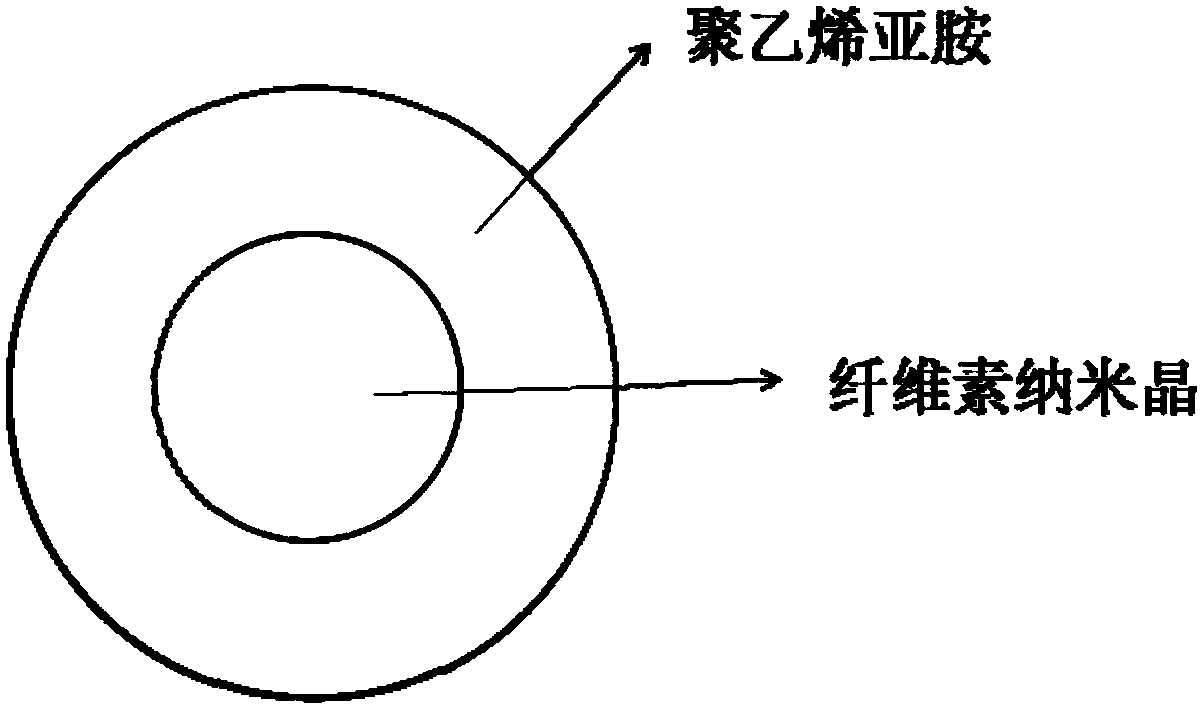

[0022] Such as figure 1 As shown, a cellulose nanocrystal-polyethyleneimine nanocomposite gene carrier, including a cellulose nanocrystal core and a polyethyleneimine shell coated outside the core, a cellulose nanocrystal core and polyethyleneimine The shell layers are closely matched, and the inner core and the outer shell are made of different materials: the inner core material is cellulose nanocrystal, and the outer shell material is polyethyleneimine.

[0023] Add polyethyleneimine (molecular weight 25kDa) and 1-allyl-3-methylimidazole hydrochloride into the reaction vessel at a mass ratio of 1:20, and mix thoroughly for 1 hour at a temperature of 60°C, and the cellulose nano Crystalline (mass ratio of 0.5:1 to polyethyleneimine) was added into the reaction vessel, stirred and reacted to obtain a cellulose nanocrystal-polyethyleneimine composite. Add epichlorohydrin with a molar ratio of 0.5 times polyacetimide to the complex, and stir and react at a temperature of 95° C....

Embodiment 2

[0025] Add polyethyleneimine (molecular weight 750kDa) and 1-allyl-3-methylimidazole hydrochloride into the reaction vessel at a mass ratio of 1:100, and mix thoroughly for 1 hour at a temperature of 60°C, and the cellulose nano Crystalline (mass ratio of 5:1 to polyethyleneimine) was added into the reaction vessel, stirred and reacted to obtain a cellulose nanocrystal-polyethyleneimine composite. Add epichlorohydrin with a molar ratio of 0.5 times polyacetimide to the composite, and stir and react at a temperature of 95° C. for 240 min to obtain a cellulose nanocrystal-polyethyleneimine nanocomposite gene carrier.

Embodiment 3

[0027] Add polyethyleneimine (molecular weight 100kDa) and 1-allyl-3-methylimidazole hydrochloride into the reaction vessel at a mass ratio of 1:50, and mix thoroughly for 1 hour at a temperature of 60°C, and the cellulose nano Crystalline (mass ratio of 1:1 to polyethyleneimine) was added into the reaction vessel, stirred and reacted to obtain a cellulose nanocrystal-polyethyleneimine composite. Add epichlorohydrin with a molar ratio of 2.5 times of polyacetimide to the composite, and stir and react at 85° C. for 180 min to obtain the cellulose nanocrystal-polyethyleneimine nanocomposite gene carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com