Dyeing-finishing pretreatment combination machine capable of recycling waste water

A technology of combining machine and pretreatment liquid, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the processing of liquid/gas/steam textile materials, etc., to achieve the effect of not easy to curl, reduce production cost, and not easy to color flower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

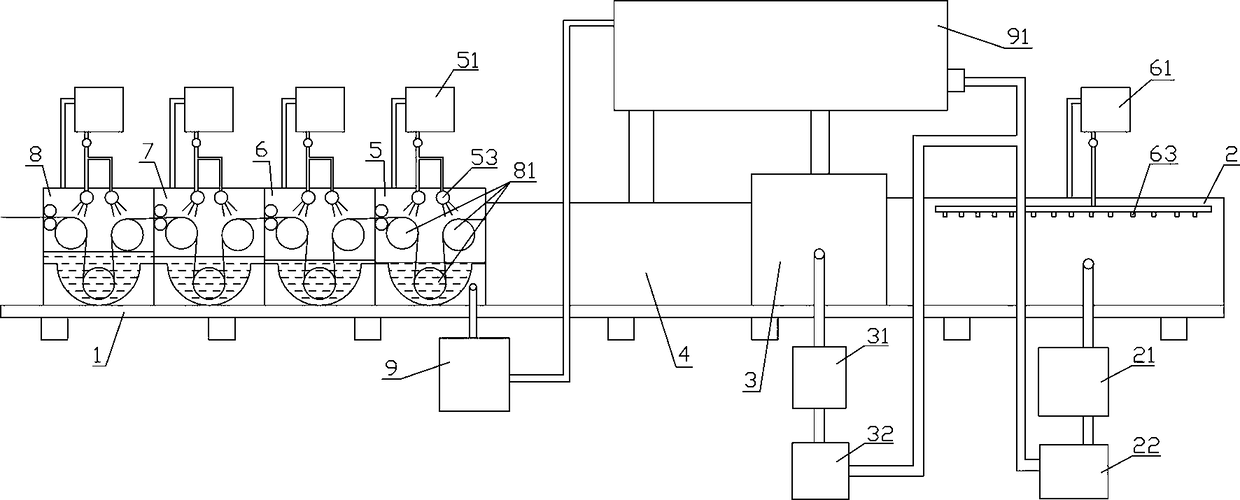

[0017] like figure 1As shown, a dyeing and finishing pretreatment combined machine that can reuse wastewater includes: a frame 1, and a scouring machine that can use a pretreatment liquid containing a pretreatment auxiliary agent to scorch the fabric is arranged on the frame 1 2. A filter screen is arranged on the spray pipeline of the scouring machine 2, so that the scouring machine 2 can filter the pretreatment liquid extracted from the water tank of the scouring machine 2 in real time during the scouring and spraying, so that the pretreatment liquid The impurity in the water is reduced, so that it can be reused repeatedly, and the filtered impurities can be manually taken out by workers; The scouring machine 2 is a kind of scouring equipment that can carry out open-width scouring to the fabric and can spray the pretreatment liquid on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com