Ground source heat pump ground source well backfill material and backfill method

A ground-source heat pump and ground-source well technology, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as low thermal conductivity, uncompact backfill, increase initial investment, etc., and achieve high comprehensive thermal conductivity and high backfill density , Good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Three kinds of backfilling materials are screened out through on-site backfilling and testing. The specific ratio of backfilling materials is as follows:

[0050] Backfill material ratio table

[0051] Material 1

Bentonite(1)

Quartz Sand(7)

Puree (2)

Material 2

Bentonite(3)

Quartz Sand(7)

Puree(0)

Material 3

cement (1)

Quartz Sand(7)

Puree (2)

[0052] Note: The numbers in brackets represent parts by volume

[0053] At the ground source heat pump construction site, after the ground source well is drilled, the volume of the backfill is obtained according to the volume of the drilled well and the volume of the U-shaped heat exchanger, and then calculated according to the volume ratio of the backfill of each component in the above table. The volume of each component, mix all the backfill materials together, place them in a mixer, add water and stir evenly, inject them into the ground source well through a gro...

Embodiment 2

[0065] A backfilling material for a ground source well of a ground source heat pump, comprising: bentonite, raw slurry, and quartz sand, and the volume ratios of the components are: bentonite: 2, raw slurry: 2, and quartz sand: 6. The quartz sand is 90 mesh, and the bentonite is sodium-based bentonite. After mixing the above raw materials, add water in a ratio of 1:1, and mix and stir at room temperature.

[0066] The above-mentioned backfill is made into a solid test block, placed for 24 hours, and then crushed. It can be seen intuitively that there are few internal gaps, high compactness, increased volume, and good expansion performance.

Embodiment 3

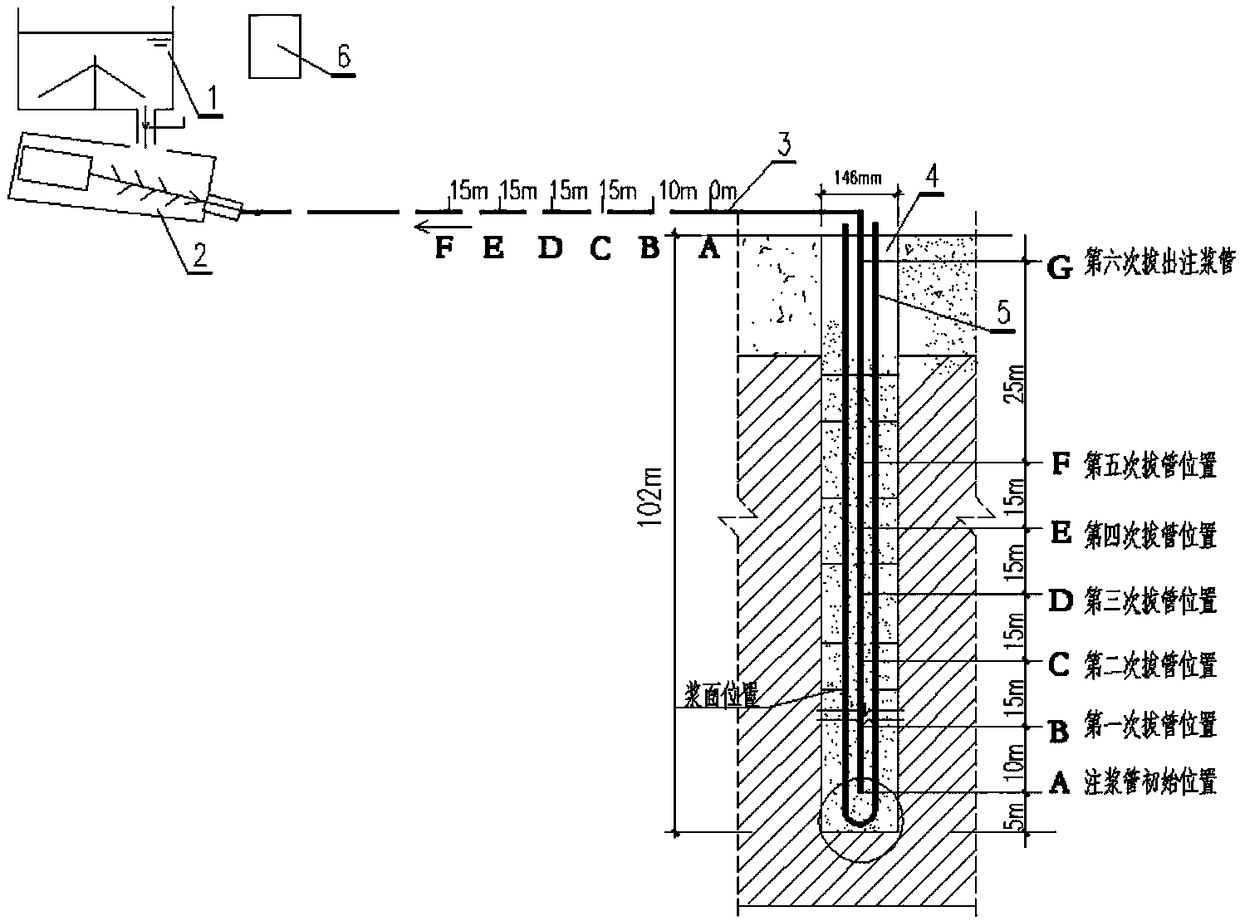

[0068] A ground source well backfilling method, the steps are as follows:

[0069] S1. Calculate the required filler volume, and add the filler to the mixer 1 in batches;

[0070] S2, the grouting pipe 3 is inserted into the bottom of the ground source well together with the double U heat exchanger 5;

[0071] S3, the grouting material is filled by back pressure grouting from the bottom of the deep well through the grouting pipe 3;

[0072] S4. Gradually lift the grouting pipe 3, and gradually discharge the original air and moisture in the well through the overflowing slurry;

[0073] S5. Until the grouting material flows out from the wellhead of the ground source, the backfilling of the entire deep well is completed.

[0074] Further, the method of lifting the grouting pipe 3 is a step-by-step lifting method, that is, the grouting pipe 3 is lifted by X meters from the bottom of the well in Y steps, each time by Z meters.

[0075] Further, the method for lifting the groutin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com