Intelligent miniature constant-flow low-pulse high-temperature plunger pump

A low-pulse, plunger pump technology, used in piston pumps, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as low lubrication characteristics, large pump volume, easy vaporization, etc. Pulse, improve the efficiency of the pump, the effect of increasing the temperature of the medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following examples are specifically cited. The combustion pump used in a 50,000 kcal boiler needs a pressure of 8 kg and a flow rate of about 6-8 liters / hour. The detailed description is as follows, but the present invention is not limited thereto.

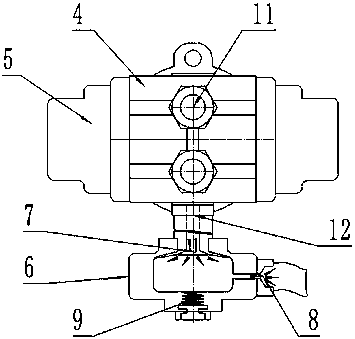

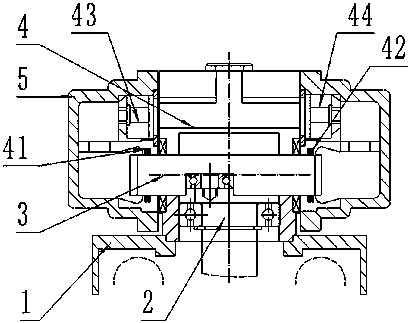

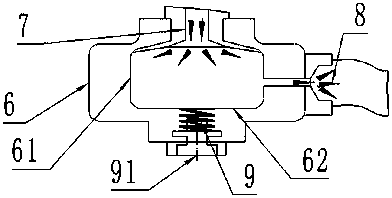

[0019] refer to Figure 1 to Figure 3

[0020] An intelligent micro-constant-current low-pulse high-temperature plunger pump, which is suitable for use on boilers for reforming biomass oil combustion burners, includes an intelligent control motor 1, and an eccentric drive rotor for connecting with the output shaft of the drive motor Device 2, two-way plunger 3, pump body 4, pump cover 5, left seal 41, right seal 42, oil inlet check valve 43, oil outlet check valve 44, oil inlet 11, pulse elimination device 6, Pressure heating device A, pressure heating device B; it is characterized in that, descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com