Heat-insulation protective fabric and application thereof

A technology of fabric and heat insulation layer, applied in the textile field, can solve problems such as hindering the dissipation of human sweat and heat, life-threatening, stuffy heat, etc., and achieve the effect of reducing overall weight and complexity, not easy to break, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

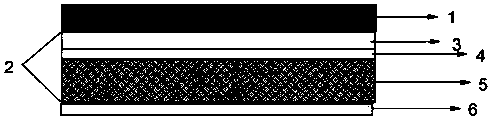

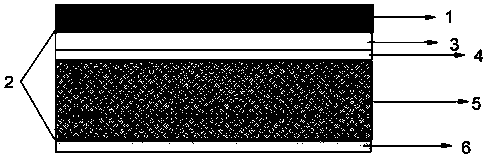

[0024] Such as figure 1 As shown, a heat-insulating and protective fabric includes: a flame-retardant outer layer 1 , a heat-insulating layer 2 and a comfortable inner layer 6 . The heat insulation layer is composed of an aluminum plating layer 3 , a waterproof and moisture-permeable film 4 and a base cloth 5 . The aluminum-coated layer 3 is located outside the waterproof breathable membrane 4, and the waterproof breathable membrane 4 and the base cloth layer 5 can be bonded together in a high-temperature-resistant, flame-retardant adhesive. The shape memory fiber fabric inside the fiber fabric is composed of shape memory fiber fabric, which is first processed into a non-planar shape, and then processed into a flat shape for use.

[0025] In this example, the waterproof and breathable membrane used is a PTFE membrane

[0026] In this example, the base fabric layer used is composed of fiber fabric and shape memory fiber fabric inside the fiber fabric. The shape fiber fabric i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com