Modular filter element upper cover assembly for diesel filter

A diesel filter, modular technology, used in engine components, machines/engines, liquid fuel feeders, etc., can solve the problems of complicated filter assembly and installation, low integration, and not easy to re-ignite, etc. To achieve the effect of facilitating the assembly process and improving the assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

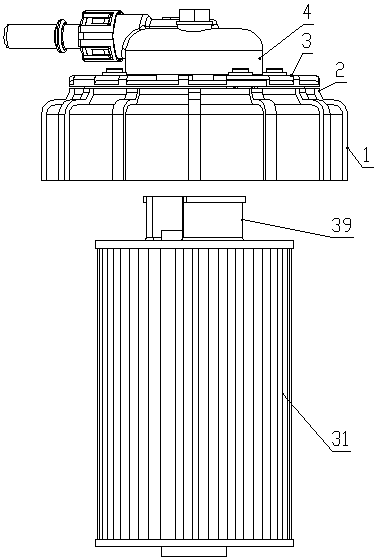

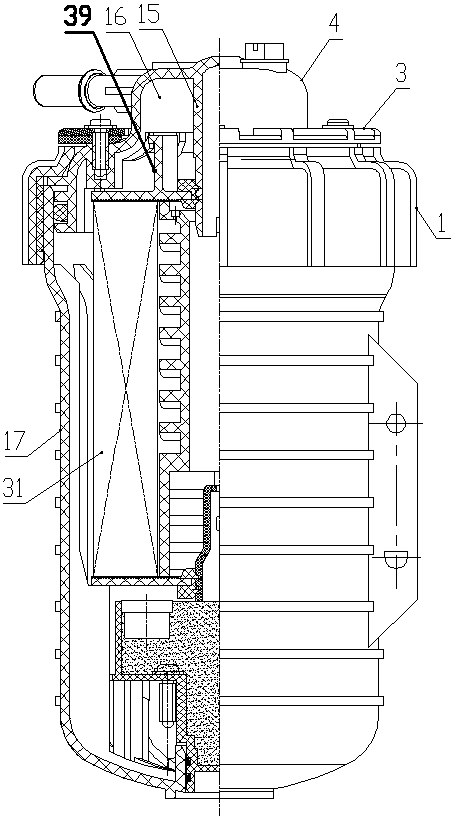

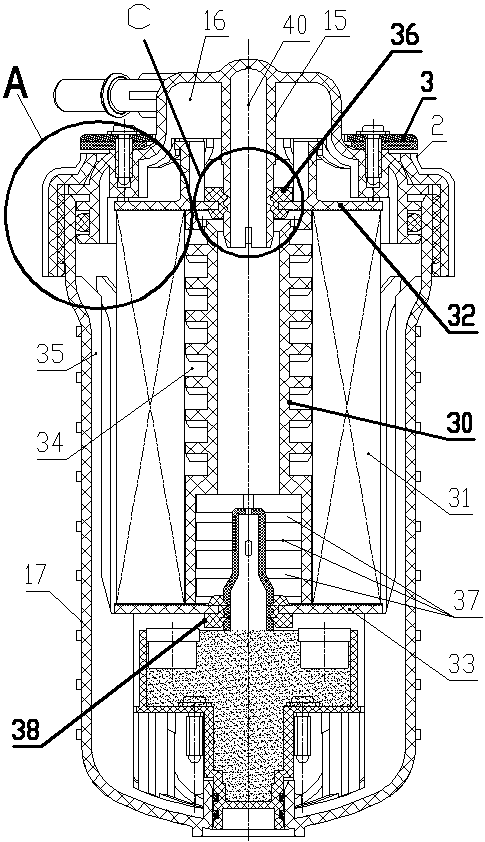

[0035] like Figure 1 to Figure 7 As shown, the modular filter element upper cover assembly for diesel filters of the present invention includes an upper housing assembly and a filter element assembly. In use, the present invention is assembled with the cylindrical lower housing assembly 17 as a complete diesel filter.

[0036]The upper casing assembly includes a main body part, a cylindrical screw cap 1 and a gland part, and the vertical centerlines 40 of the three are the same straight line; The direction to the centerline 40 is the outer direction;

[0037] The top of the screw cap 1 is provided with a constriction part 2; the gland part includes more than two gland ring segments 3, and all the gland ring segments 3 are spliced into an annular shape along the circumferential direction on the same horizontal plane;

[0038] The main part includes a cover cylinder 4, a shoulder 5 and a connecting cylinder 6 which are connected in sequence from top to bottom. The diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com