Pulse-controlled silicon controlled rectifier floating charger

A pulse control, thyristor technology, applied in the field of electronics, can solve problems such as affecting battery capacity and life, battery environment pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

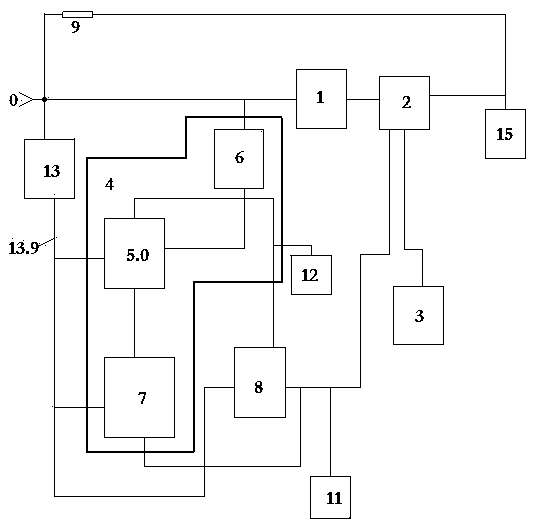

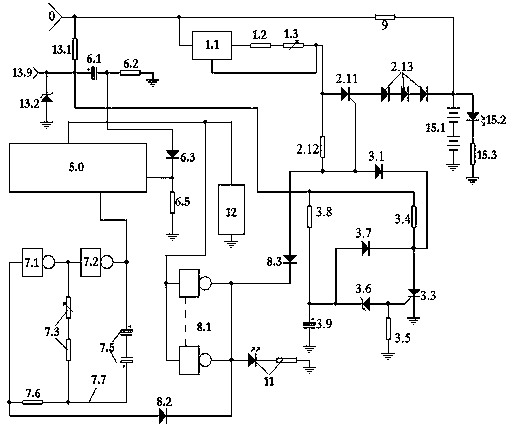

[0095] figure 1 , 2 , 3, 4, 5 examples have gone out a kind of implementation making example.

[0096] 1. Selection of components: The pulse capacitor adopts a non-polar capacitor.

[0097] The excitation parallel gate and the gate 1 circuit and the gate 2 circuit are welded by an inverter inside an integrated circuit CD4069, and the excitation parallel gate is connected in parallel with four inverters.

[0098] The charging display unit is composed of a charging display luminous tube connected in series with a charging display protection resistor.

[0099] The current limit indicator is an LED.

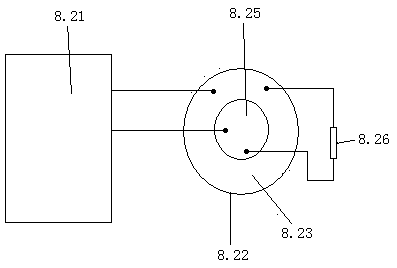

[0100] 2. Plate making and welding: press figure 2 To make the circuit control board, press figure 2 Schematic of soldered components. Pronunciation as image 3 Welded as shown.

[0101] 3. Power-on inspection and debugging.

[0102] 1. Check the constant current source part.

[0103] Connect a triode to form an adjustable voltage regulator analog circuit instead of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com