Preparation method of peeled and expanded full-fat soybean powder capable of replacing fish meal

A full-fat soybean, fish meal replacement technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of high degree of protein denaturation, long product heating time, high degree of oil oxidation, and achieve digestion and absorption rate. High, the effect of weight gain is obvious, and the effect of nutrient loss is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

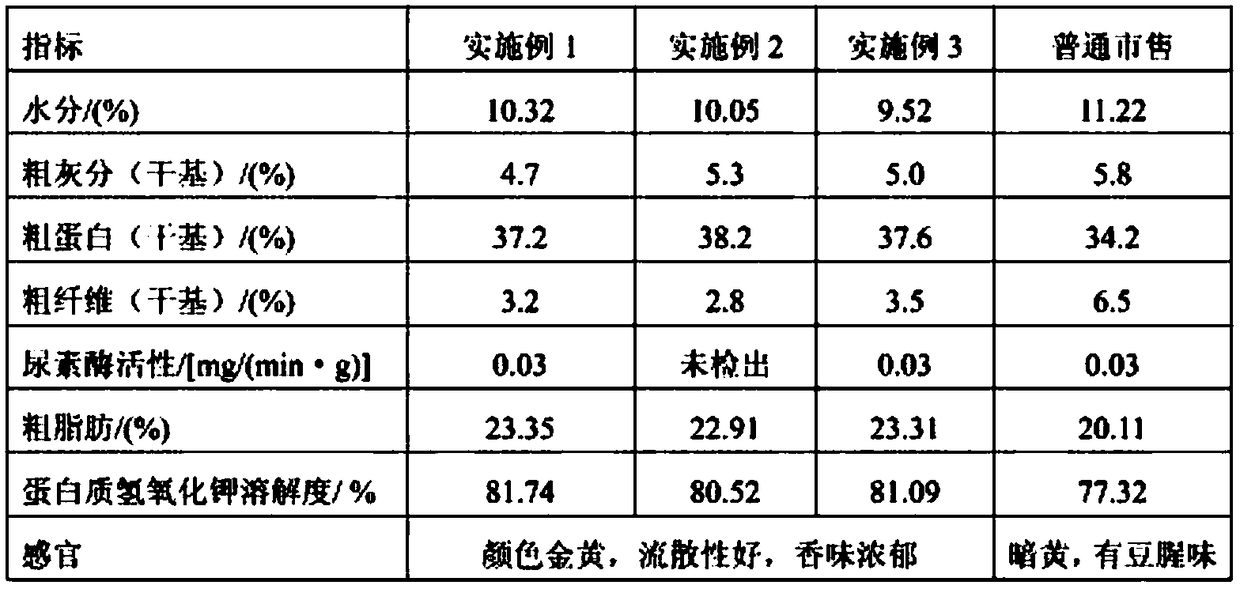

Examples

Embodiment 1

[0025] A method for preparing peeled and expanded full-fat soybean meal that can replace fish meal, comprising the following steps:

[0026] (1) Imported soybeans are selected to remove impurities; the overall temperature is uniformly raised in the drying tower, and the drying time is 40 minutes, the drying temperature is 65°C, and the air inlet temperature is 130°C; after that, the soybean hulls are removed by peeling and winnowing. After passing through the sheller, soybeans are broken into 2 to 4 cloves, and the separation rate of bean cloves and bean skins is ≥95%; the whole bean rate after crushing is less than 5%; the powder degree is less than 5%. After winnowing, Douban contains less than 1% of separated bean skin.

[0027] (2) The soybeans were further crushed into soybean powder, and tempered with 80°C steam, and the tempering time was controlled to be 25s by controlling the feeding speed. Sampling test shows that the moisture content of soybean flour is 22.21%, and...

Embodiment 2

[0030] A method for preparing peeled and expanded full-fat soybean meal that can replace fish meal, comprising the following steps:

[0031] (1) Imported soybeans are selected to remove impurities; the overall temperature is uniformly raised in the drying tower, and the drying treatment time is 60 minutes, the drying temperature is 55°C, and the inlet air temperature is 110°C; after that, the soybean hulls are removed by peeling and winnowing. After passing through the sheller, soybeans are broken into 2 to 4 cloves, and the separation rate of bean cloves and bean skins is ≥95%; the whole bean rate after crushing is less than 5%; the powder degree is less than 5%. After winnowing, Douban contains less than 1% of separated bean skin.

[0032] (2) The soybeans were further crushed into soybean powder, and tempered with steam at 110°C, and the tempering time was controlled to be 15s by controlling the feeding speed. Sampling test shows that the moisture content of soybean flour ...

Embodiment 3

[0035] A method for preparing peeled and expanded full-fat soybean meal that can replace fish meal, comprising the following steps:

[0036] (1) Imported soybeans are selected to remove impurities; the overall temperature is uniformly raised in the drying tower, and the drying time is 50 minutes, the drying temperature is 50°C, and the air inlet temperature is 120°C; after that, the soybean hulls are removed by peeling and winnowing. After passing through the sheller, soybeans are broken into 2 to 4 cloves, and the separation rate of bean cloves and bean skins is ≥95%; the whole bean rate after crushing is less than 5%; the powder degree is less than 5%. After winnowing, Douban contains less than 1% of separated bean skin.

[0037] (2) The soybeans were further crushed into soybean powder, and tempered with 100°C steam, and the tempering time was controlled to be 20s by controlling the feeding speed. Sampling test shows that the moisture content of soybean flour is 20.10%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com