Cylindrically laminated stainless steel fiber porous material and energy absorption compound pipe

A porous material, stainless steel technology, applied in the direction of metal layered products, layered products, springs, etc., can solve the problems of complex weaving equipment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The ultra-fine soft 304 stainless steel rope with a diameter of 0.5mm twisted by 49 stainless steel fibers is knitted with a 3.5mm diameter crochet needle and 10 stitches of lock stitches are used as starting stitches. Stir up the Satoyama and half needles of the needle, hang the thread on the needle, pull out the thread, hang the thread again, draw and pull through the 2 loops on the crochet needle, knit 1 short stitch, and repeat this process to finish the first row. Crochet 1 stitch with the standing stitch, turn the right end of the crochet fabric outward, insert the crochet needle into the 2 lock stitches of the header needle of the short needle at the right end of the first row, and then knit in the short needle. Repeat this to finish row 2. After that, each row is carried out according to the method of the second row, and a total of 16 rows are crocheted, woven into stainless steel wire rope woven sheets, rolled into round rods, placed in a quartz tube with an in...

Embodiment 2

[0059] Using the method of Example 1, 10 lock stitches are used as starting needles, and a total of 13 rows are crocheted to form a single-bundle continuous metal rope crochet sintered cylindrical layer with an outer diameter of about 23 mm, a height of about 50 mm, and a porosity of about 85%. porous material.

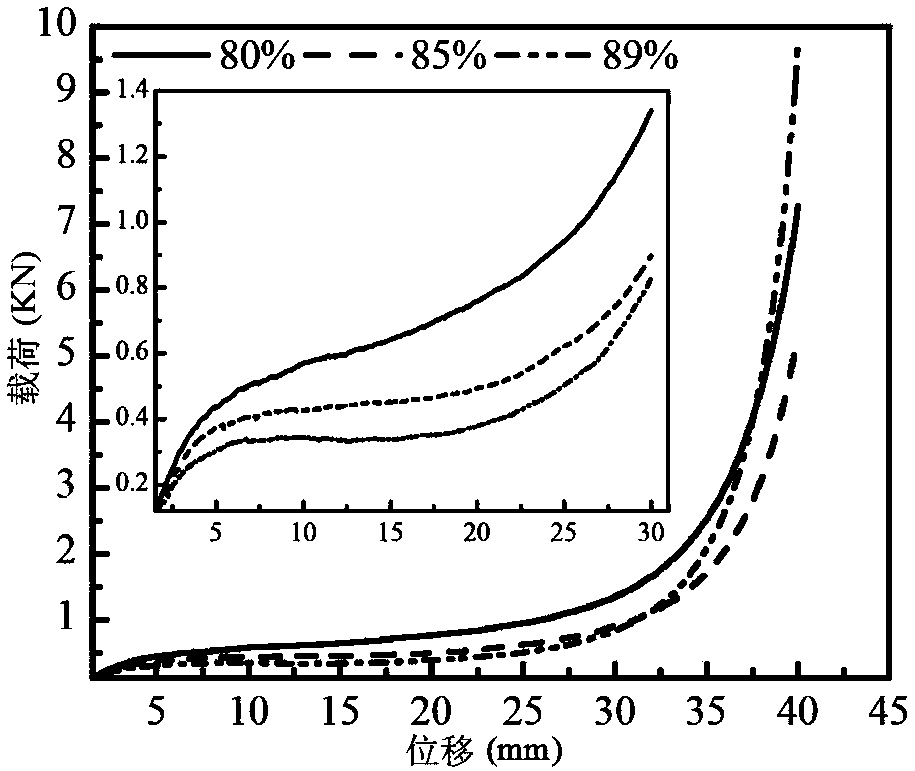

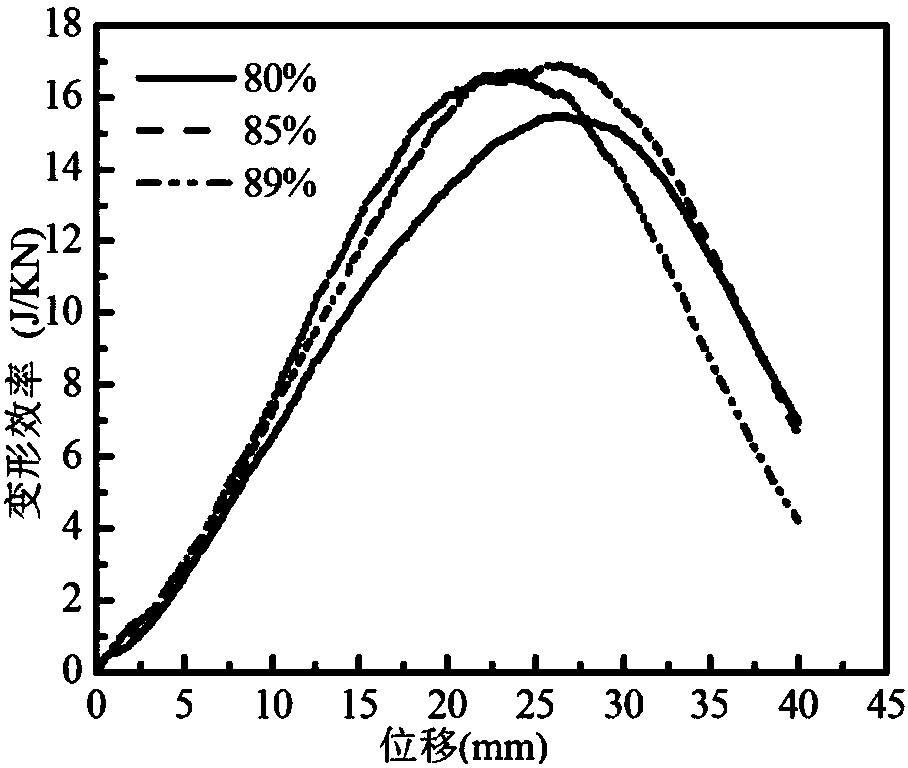

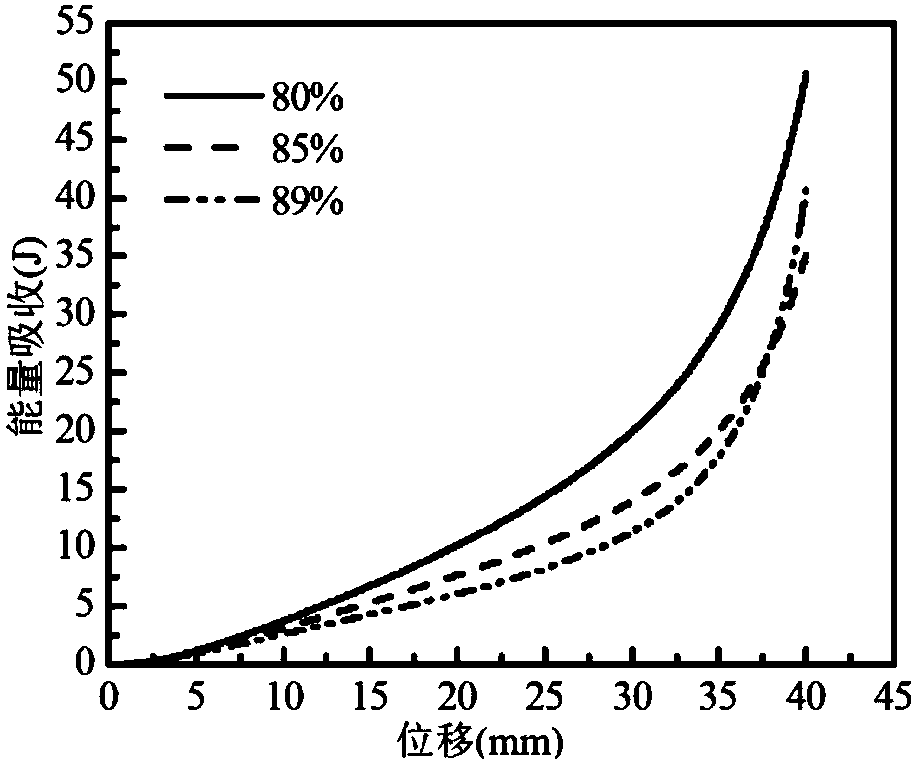

[0060] The axial quasi-static load-displacement curves of a single-bundle continuous metal rope hook-woven sintered cylindrical layered porous material with a porosity of about 85% in Example 2 include a short elastic phase, a long and stable energy-absorbing plastic platform phase and a dense compaction stage (see figure 1 ). The elastic stage transitions smoothly to the plastic platform stage, the initial crushing peak value is only 0.38KN, and the effective crushing length is 34.10mm (see figure 2 ), its effective stroke ratio is 0.62, and the total amount of effective absorbed energy is 18.69J (see image 3 ), the average crushing load is 0.55KN, and the load ...

Embodiment 3

[0062] Using the method of Example 1, 10 lock stitches are used as starting needles, and a total of 10 rows of crochet are used to form a cylindrical single-bundle continuous metal rope crochet sintered cylinder with an outer diameter of about 23 mm, a height of about 50 mm, and a porosity of 89%. shaped porous volume.

[0063] The axial quasi-static load-displacement curve of the single-bundle continuous metal rope hook-woven sintered cylindrical layered porous body material with a porosity of about 89% in Example 3 consists of a short elastic stage, a long and stable energy-absorbing plastic platform stage and a compact compaction stage (see figure 1 ). The elastic stage transitions smoothly to the plastic platform stage, the initial crushing peak value is only 0.32KN, and the effective crushing length is 33.46mm (see figure 2 ), its effective stroke ratio is 0.61, and the total amount of effective absorbed energy is 15.20J (see image 3 ), the average crushing load is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com