A kind of buffer system for preparing cobalt carbonate

A buffer system, cobalt carbonate technology, applied in the chemical industry, can solve the problem of reducing the amount of material recovery in the precision filter, and achieve the effect of improving the pumping rate, increasing the amount of material recovery, and avoiding material leakage

Active Publication Date: 2019-10-01

JINGMEN GEM NEW MATERIAL

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of blowing back the precision filter with compressed air, the pressure of the back blowing air is controlled at 0.4-0.6MPa, which makes it easy for the material to be discharged from the vent pipe set on the top of the precision filter, so that the inside of the precision filter The amount of material recycled is greatly reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

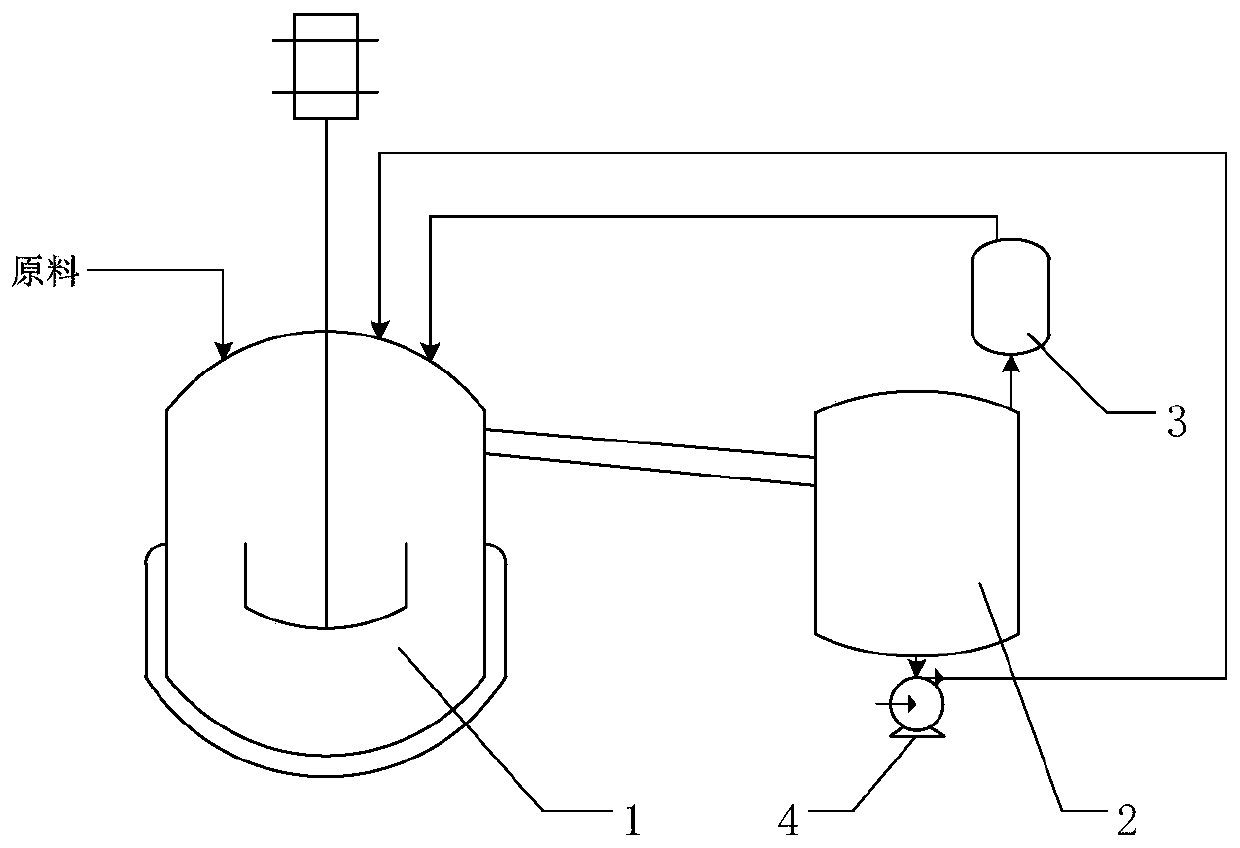

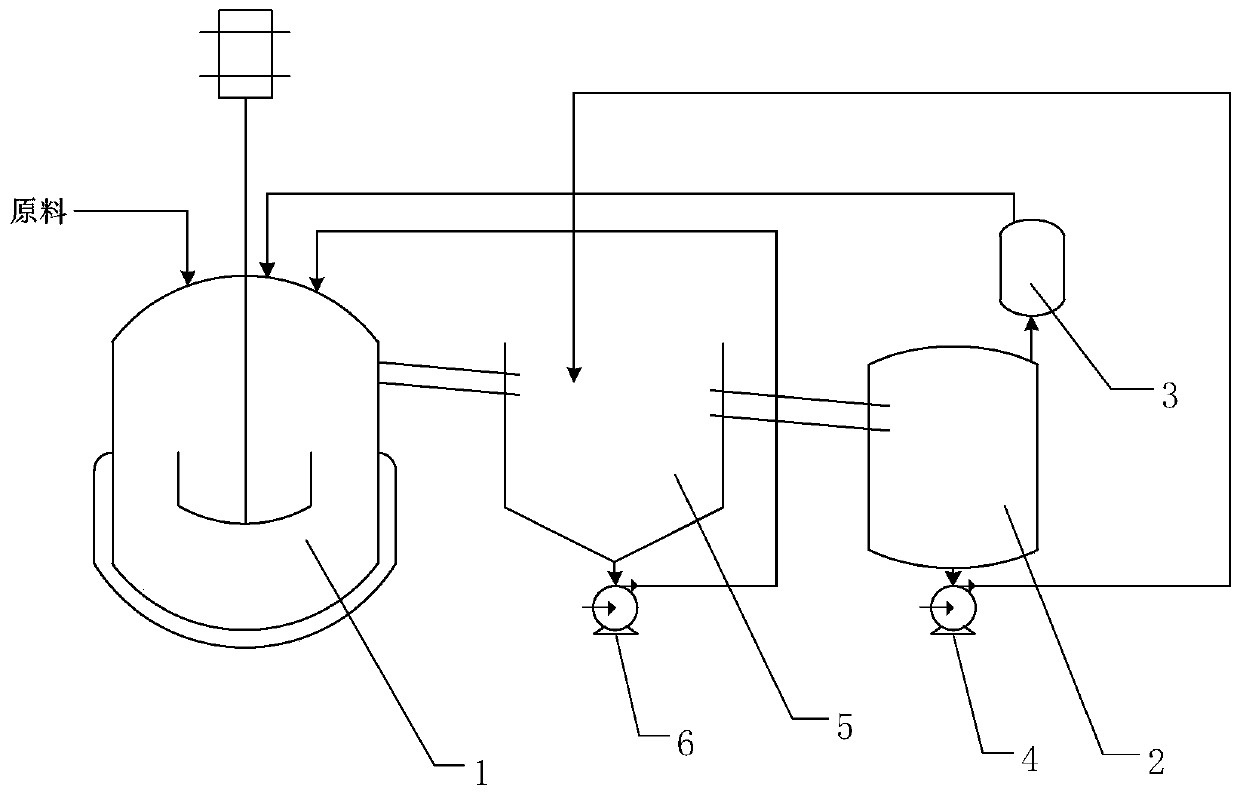

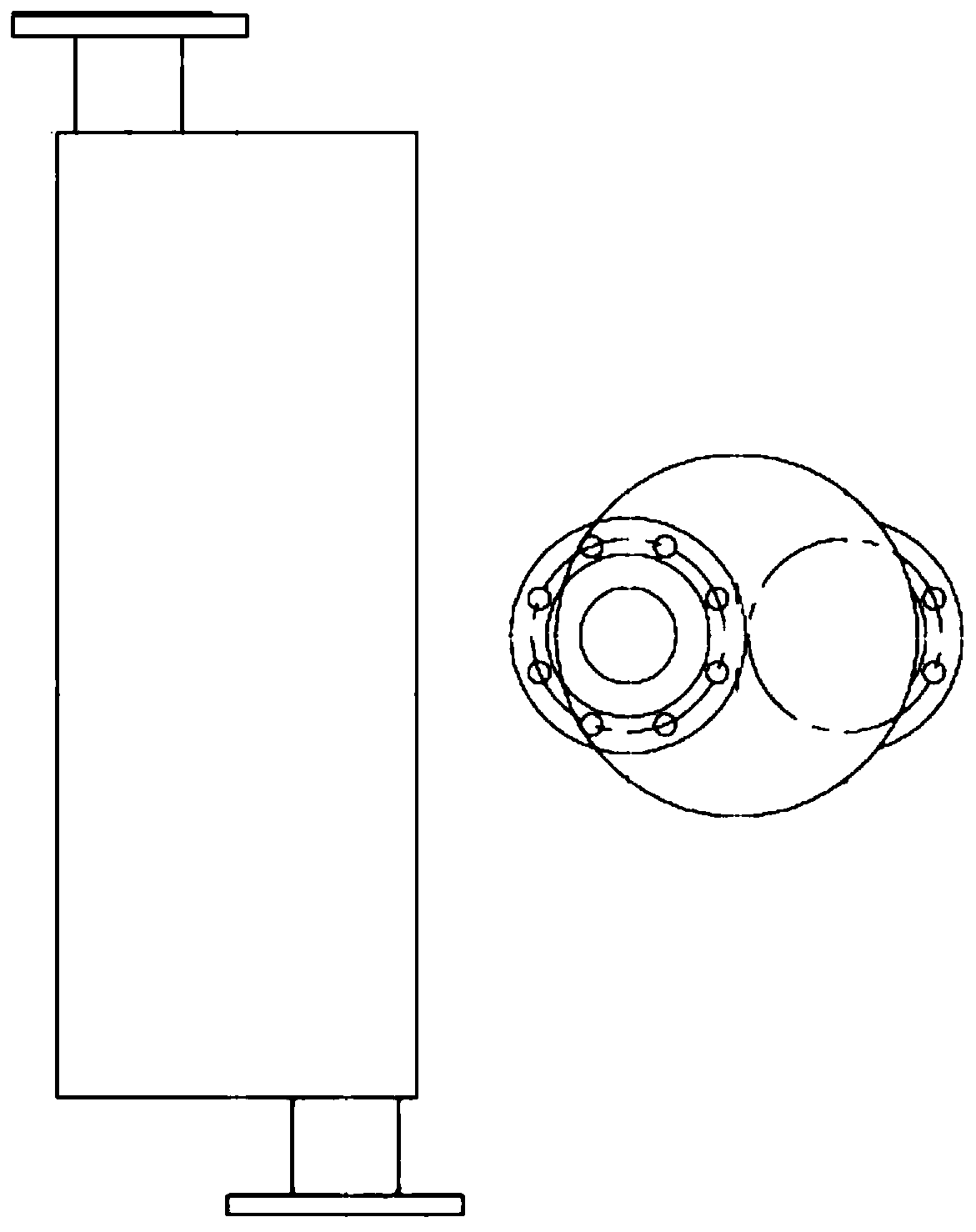

The invention provides a buffer system for preparing cobalt carbonate. The system includes a buffer tank, a precision filter and a reaction kettle; an inlet of the bottom of the buffer tank is connected to an opening of the top of the precision filter through a pipeline; an outlet of the buffer tank is connected to a first opening of the reaction kettle through a pipeline; and an inlet of the precision filter is connected to an overflow opening of the reaction kettle, and an outlet of the precision filter is connected to a second opening of the reaction kettle through a first circulation pump.According to the system provided by the invention, the buffer tank is arranged at the top of the precision filter, so that when the precision filter utilizes compressed air to perform back blowing, the problem of material running is avoided, and the material recovery amount of the entire system is greatly improved; and meanwhile, the buffer tank can alleviate the breath holding problem in the precision filter, thereby improving the liquid pumping speed of the precision filter.

Description

technical field The invention relates to the technical field of chemical industry, more specifically, to a buffer system for preparing cobalt carbonate. Background technique Cobalt carbonate is a red monoclinic crystal or powder. Toxic, irritating to eyes, respiratory system and skin. It is mainly used as mineral dressing agent, catalyst, pigment for camouflage paint, feed, micro-fertilizer, ceramics and raw material for the production of cobalt oxide. Among them, it is mainly used to make cobalt chloride, cobalt sulfate, cobalt oxide, metal cobalt and cobalt naphthenate. It is also used to make color-changing pigments, glass pigments, ceramics, feed trace element additives and trace element fertilizers. It is used to make cobalt oxide and is the raw material for making positive electrode materials of lithium batteries. The ceramic industry is used as a colorant for the manufacture of cobalt salts and the coloring of porcelain. It is used as beneficiation agent in minin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G51/06B01D35/16

Inventor 许开华刘文泽乐绪清唐洲洪宏龙黄良取贺毅

Owner JINGMEN GEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com