Flexible fiber for working garment of dredger operator

A flexible fiber and operator technology, applied in the fiber field, can solve the problems of flexible fibers that are easy to tear, not enough, and break when pulled, and achieve the effects of increasing acid and alkali resistance, prolonging service life, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

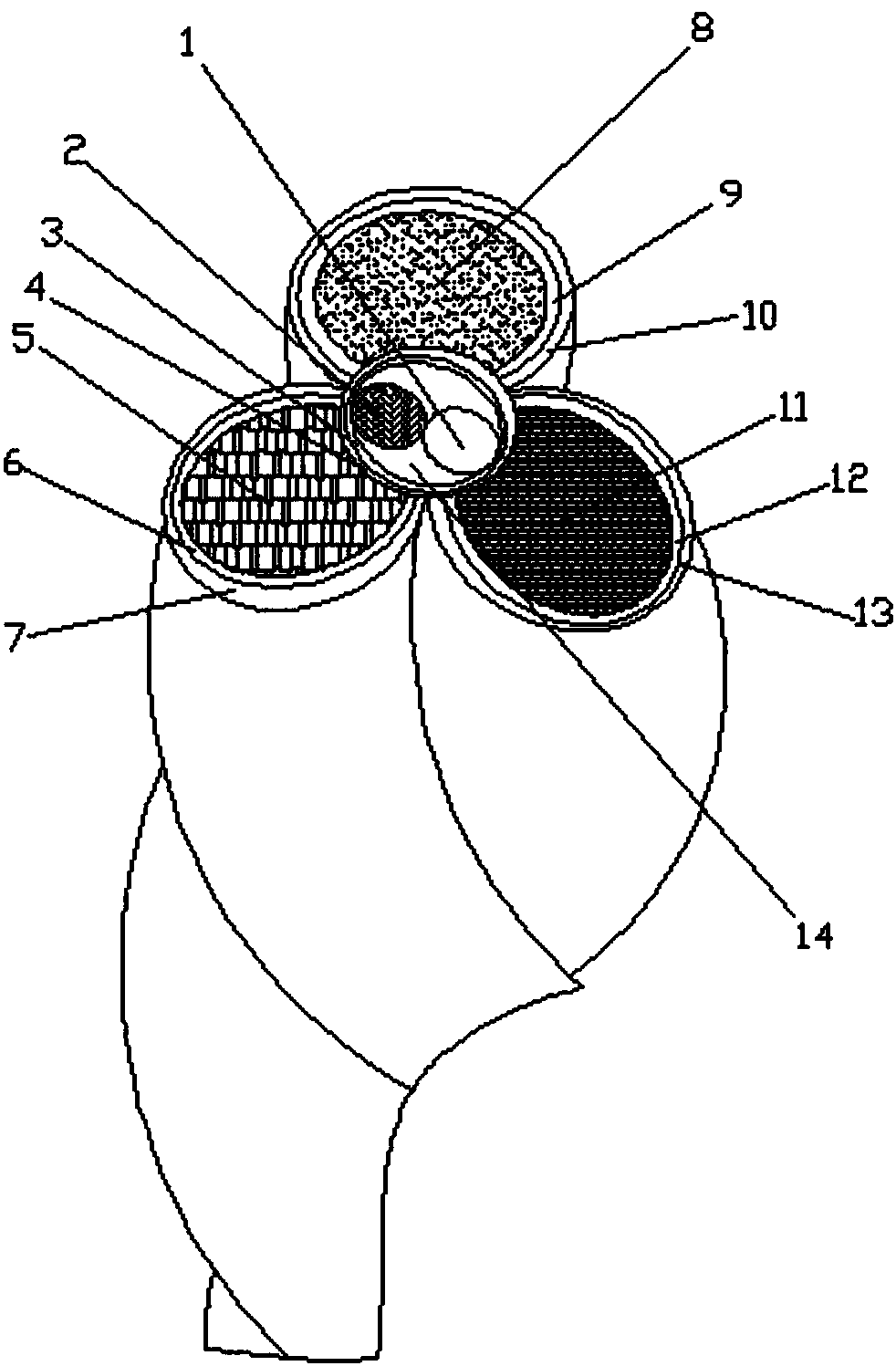

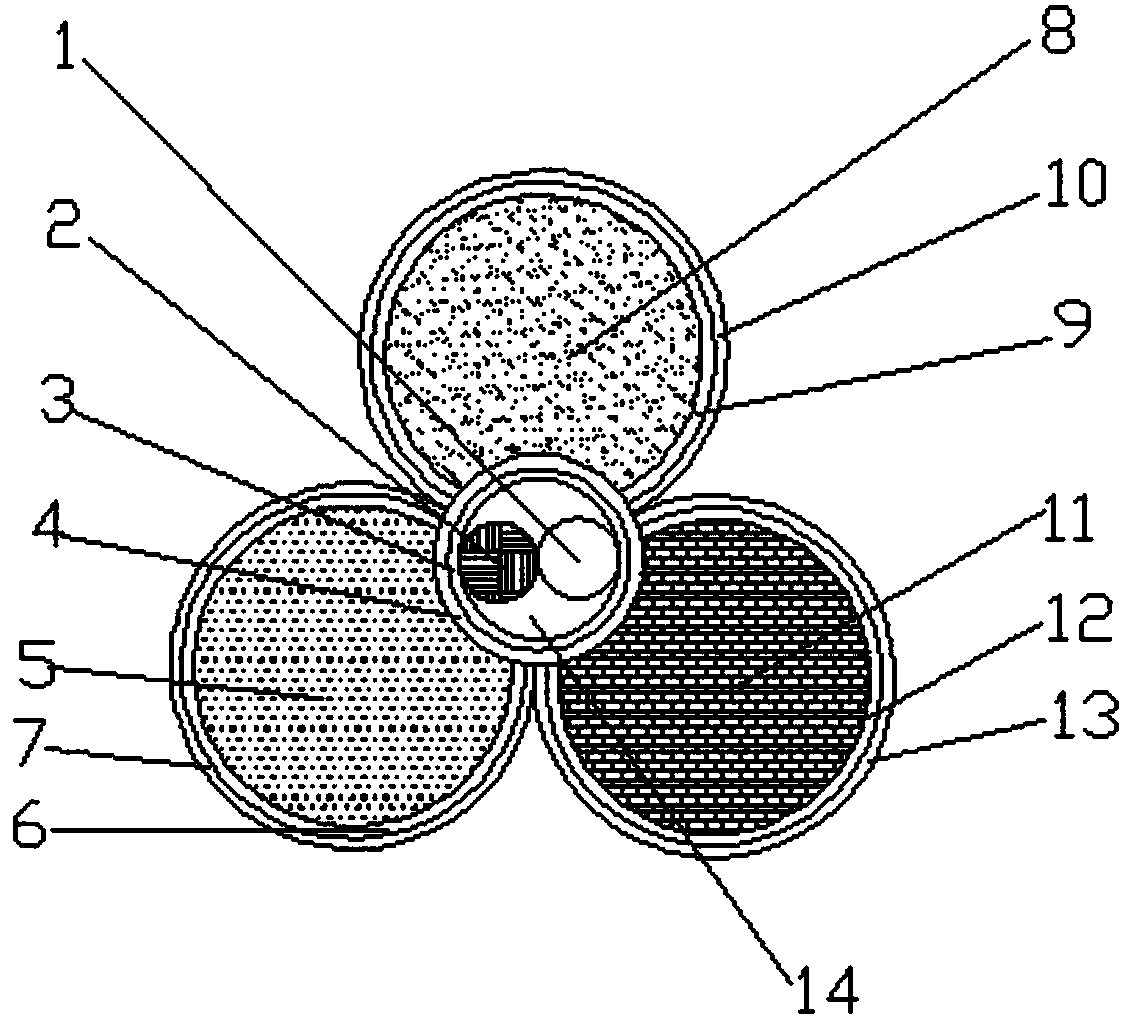

[0022] Such as Figure 1-2 As shown, a flexible fiber used for overalls of dredger operators includes a spandex core, characterized in that: the outer surface of the spandex core is entangled with a polyester core, and the spandex core and the outer polyester core The surface is covered with a first phenolic vinyl resin layer, the outer surface of the phenolic vinyl resin layer is also covered with a first epoxy resin layer, and the outer surface of the first epoxy resin layer is also wound with fluorine fiber and poly Vinyl chloride fiber and organic conductive fiber, the outer surface of the fluorocarbon fiber is covered with a second phenolic vinyl resin layer, and the outer surface of the second phenolic vinyl resin layer is covered with a second epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com