Large electric furnace system

An electric furnace, a large-scale technology, applied in the direction of industrial buildings, etc., can solve the problems of high energy consumption, small scale, waste of manpower, transportation capacity, etc., to achieve the effect of reducing cost investment, convenient assembly and construction, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

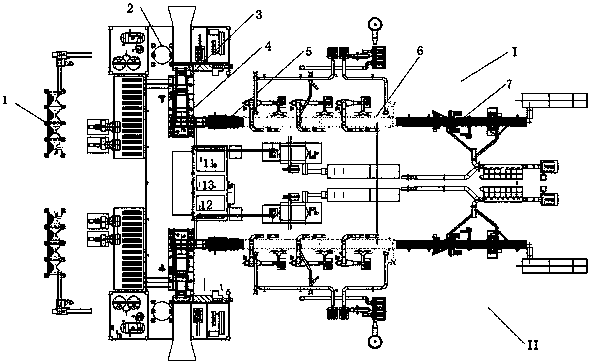

[0036] The large-scale electric furnace system of this embodiment includes a first electric furnace system I, a second electric furnace system II and a utility system, the first electric furnace system I and the second electric furnace system II have the same structure, and the first electric furnace system I includes

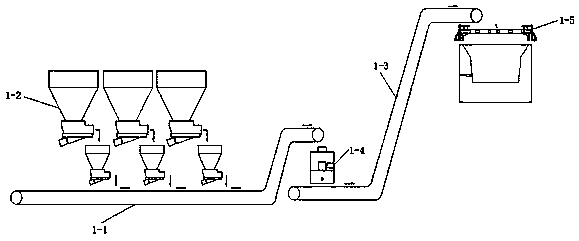

[0037] Raw material feeding device 1, including external feeding conveyor belt 1-1, feeding tank 1-2, conveyor belt 1-3, mixing device 1-4 and distributor 1-5;

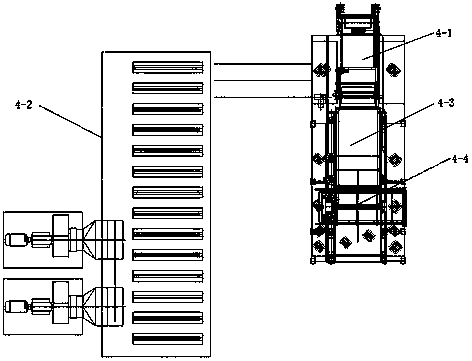

[0038] The electric furnace device 2 includes a furnace body, and the side wall at the lower end of the furnace body is provided with a stream opening;

[0039] The fiber forming device 3 includes a centrifuge, and the molten material flowing out of the electric furnace device 2 is subjected to centrifugal fiber forming treatment;

[0040] The cotton colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com