Micro/nanometer thin film-based eddy current force/deformation/pressure detection method

A nano-film and detection method technology, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of little stress, strain detection, difficulty in improving the rate of change of conductor eddy current, and being affected by distance, etc. Low production cost and the effect of increasing the degree of impedance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Taking intraocular pressure detection as the first embodiment, the detection method of the present invention is described, but this example can also be used in other required fields. The method can determine the intraocular pressure according to the impedance of the eddy current sensor of the micro / nano film, and the method can effectively detect the measured object in real time.

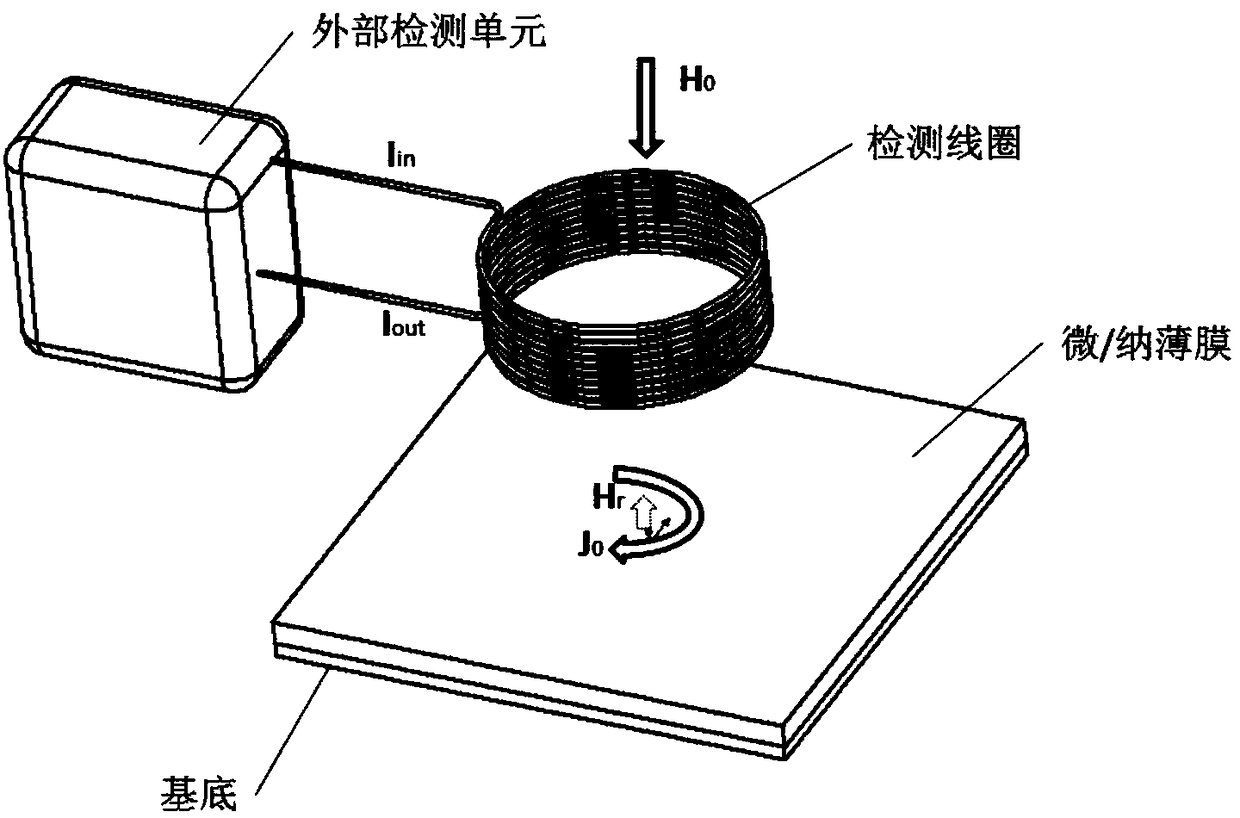

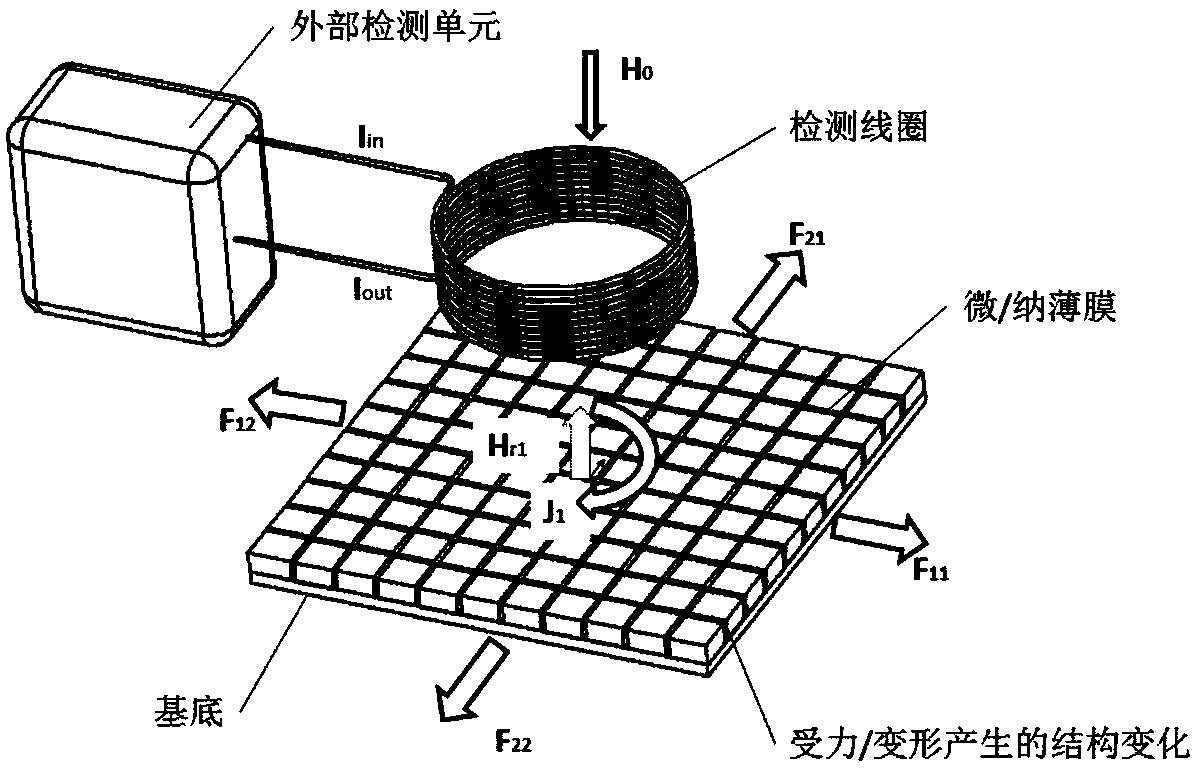

[0046] The invention constructs a wireless and passive detection method based on eddy current detection technology, including micro / nano thin film and detection circuit. The principle framework of the detection circuit is as follows Image 6 As shown, the detection circuit mainly includes: an extraocular detection unit 01 and a host computer 10 . The extraocular detection unit includes a coil module 02, a pre-circuit module 03, a control circuit module 06, a wireless communication module 07, a power circuit module 08, a battery 09, an upper position 10, etc.; the coil module 02 is an inducta...

Embodiment 2

[0058] The technical solution of the present invention will be described below by taking breathing detection as another embodiment of the present invention.

[0059] Such as Figure 7 Shown is a schematic diagram of measuring human respiration using the eddy current detection method of the micro / nano film. The micro / nano film can be placed on the corresponding parts of the human body. Like the embodiment of intraocular pressure, a detection circuit may also be provided, including an in vitro detection unit, a host computer, etc. (same as Embodiment 1). The magnitude and strain for human respiration are relatively large, and the force exerted on the film is also relatively obvious. The micro / nano film in this embodiment does not need to be provided with microstructures. The film is attached to the body surface of the human body, so the base material of the film needs to choose a material with good compatibility with the human body, and choose a polymer material PU with good c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com