Performance testing device for linear motor drive system of machine tool

A linear motor and drive system technology, applied in the direction of mechanical devices, mechanical measuring devices, motor generator testing, etc., can solve the problems of time-consuming, labor-intensive, high cost, low efficiency, etc., to avoid the risk of rework and facilitate movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

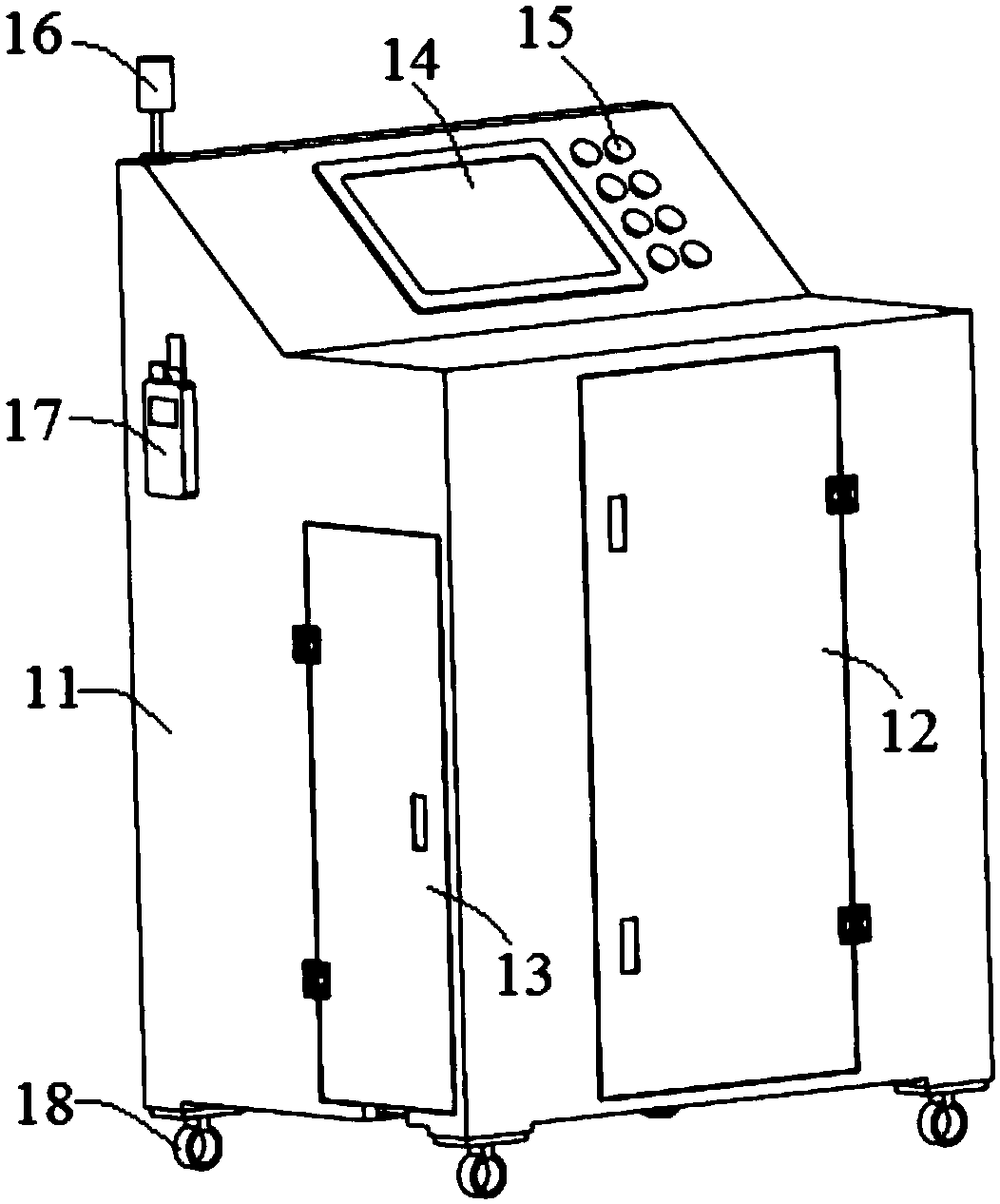

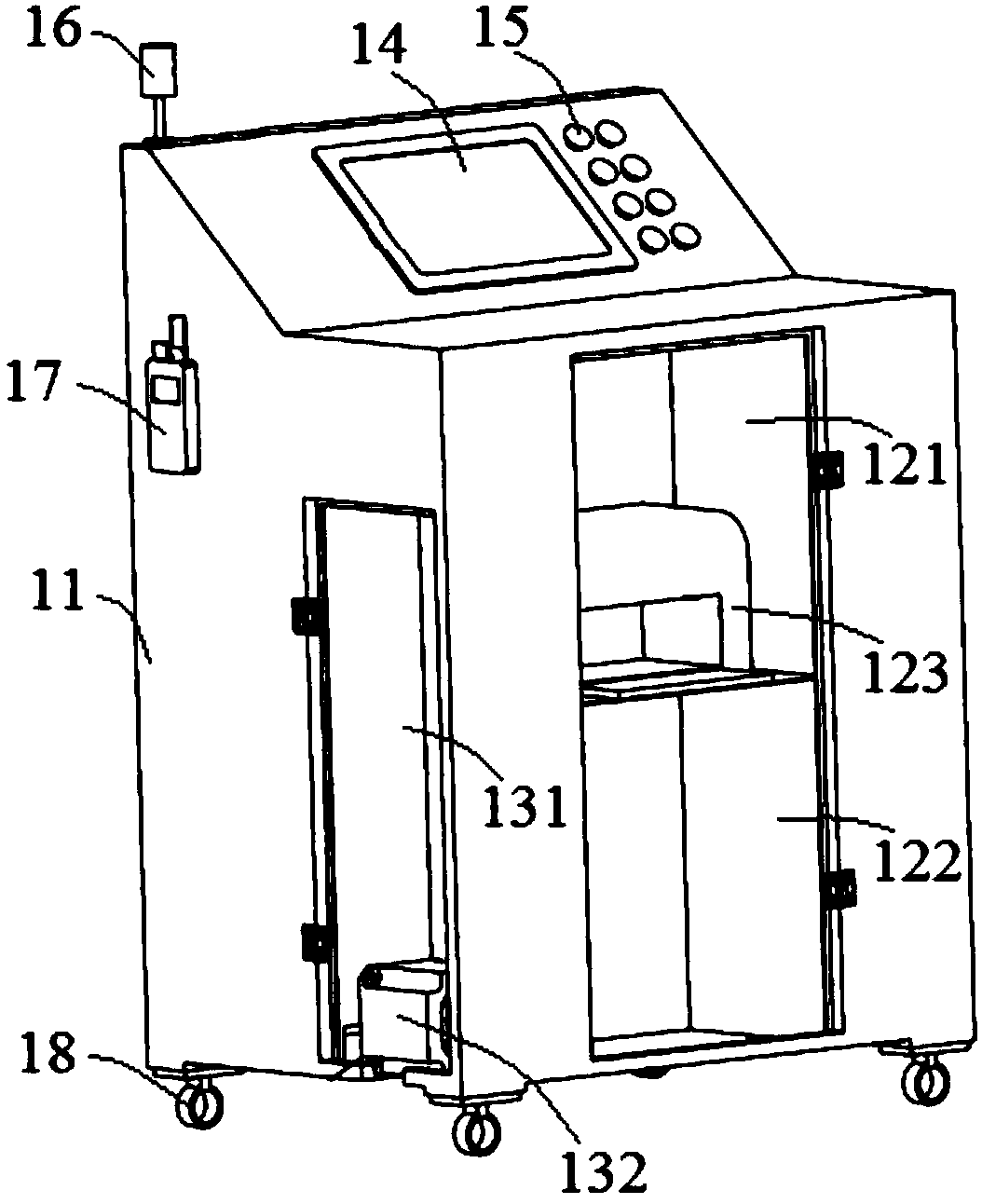

[0034] combine figure 1 and figure 2 , a machine tool linear motor drive system performance test device in this embodiment includes a cabinet 11, a test motor 132, a display screen 14, a control panel 15, a PLC control system and an electronic dial gauge 23. The PLC control system is arranged inside the cabinet 11 (not shown in the figure), and the PLC control system is the brain center of the whole test device, controlling the whole test process. The input end of the PLC control system is electrically connected with the electronic dial indicator 23, and the output end is connected with the test motor 132 through the motor control line 133, and the described test motor 132 is installed on the existing motor seat 31 on the side of the carriage 32. The display screen 14 displays the output data of the PLC control system.

[0035]In this embodiment, a control program is burned in the PLC control system, and the test motor 132 is controlled to drive the carriage 32 to reciproca...

Embodiment 2

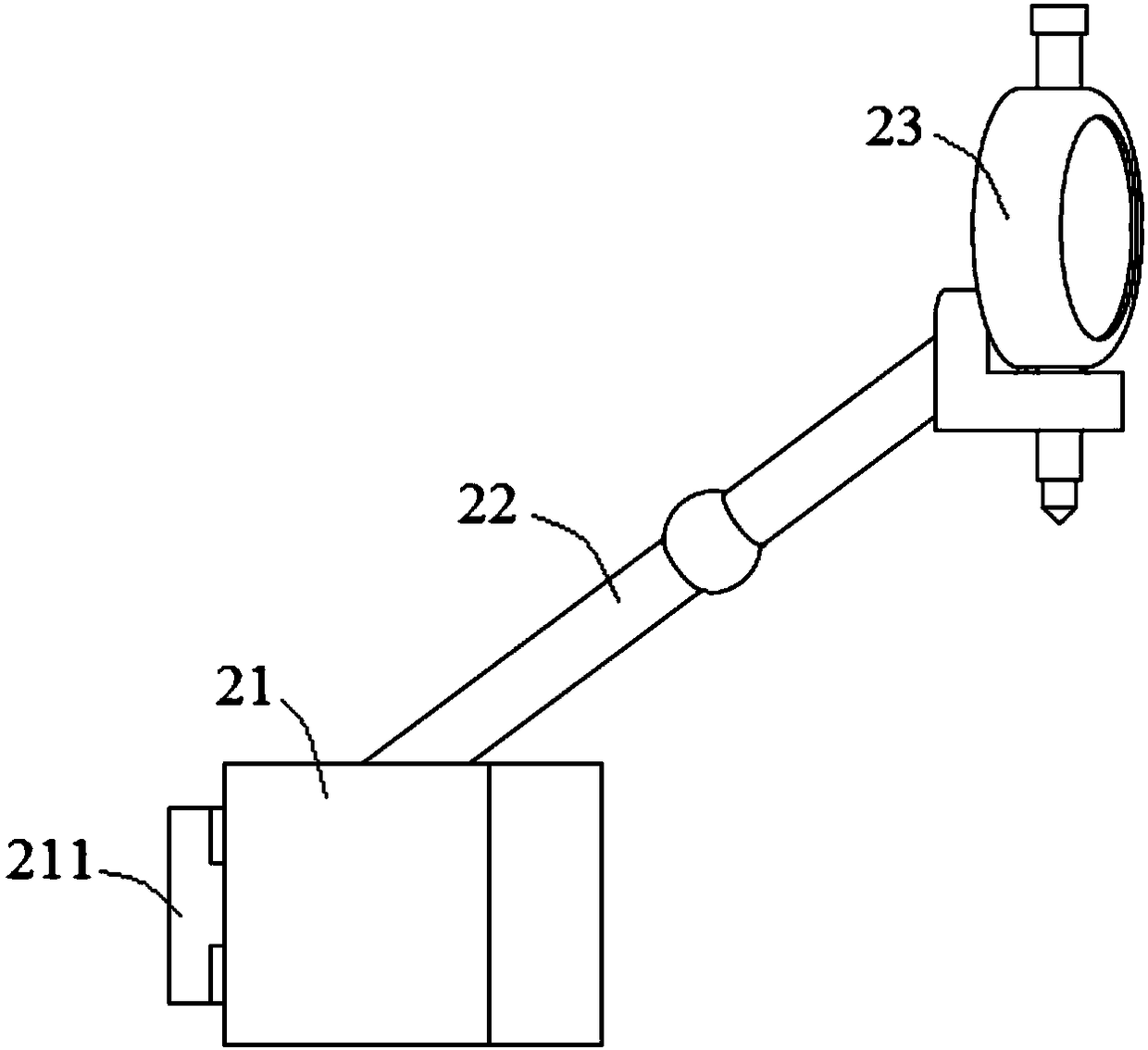

[0039] combine image 3 and Figure 4 , a kind of machine tool linear motor drive system performance test device of the present embodiment is basically the same as embodiment 1, and its difference is: described electronic dial indicator 23 is fixed on the table frame 22, and the other end of this table frame 22 The suction seat 21 is connected, and a knob 211 is arranged on one side of the suction seat 21 . The two poles of the watch frame 22 can rotate at one point, and the suction seat 21 in this embodiment adopts a magnetic seat. The cabinet body 11 is provided with an RS232 communication interface, the electronic dial indicator 23 is connected to the signal line 24, and the other end of the signal line 24 is inserted into the RS232 communication interface to be connected with the PLC control system.

[0040] A kind of machine tool linear motor drive system performance test device of the present embodiment, self-fitting test motor 132, after the machine tool mechanical pa...

Embodiment 3

[0042] combine figure 1 and figure 2 , a kind of machine tool linear motor drive system performance test device of this embodiment is basically the same as embodiment 1, and its difference is: present embodiment is also provided with hand wheel 17 on one side of cabinet body 11, and this hand wheel 17 It is a pulse hand wheel, which is electrically connected with the PLC control system. The signal can be generated by manually controlling the pulse hand wheel and input to the PLC control system, so that the PLC control system controls the test motor 132 to drive the carriage 32 to move within the specified stroke. In this way, the stroke range of the carriage 32 can be determined before the automatic test. Inside, whether there is any obstacle, to ensure the smooth progress of the test and the safety of the movement of the carriage 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com