Anti blue-ray lens coating method

An anti-blue light and lens technology, which is applied in optics, optical components, instruments, etc., can solve the problems of no anti-blue light and ultraviolet rays, single function, and no flat lenses suitable for ordinary people to prevent blue light and ultraviolet rays, so as to ensure human health, Delays the deepening of vision and relieves visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

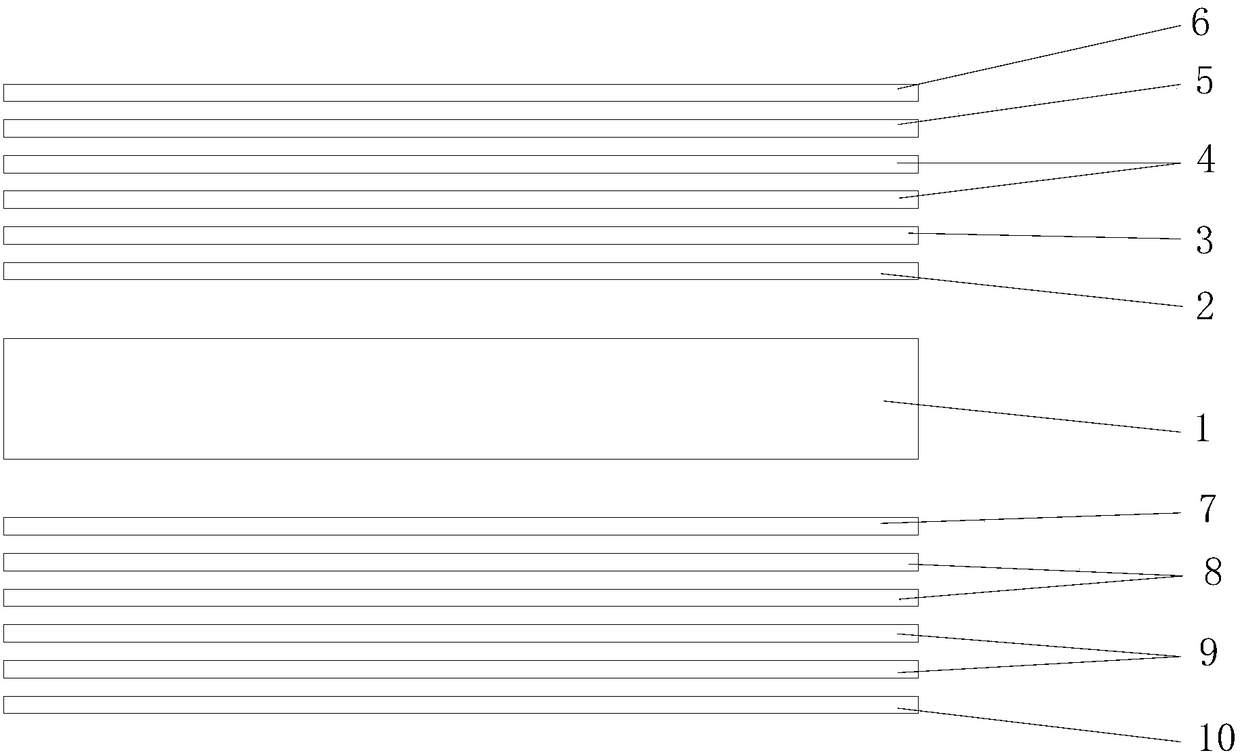

[0072] Example 3: 50% silicon oxide and 50% zirconium oxide.

[0073] The embodiment of the optical control film layer 5 film material component on the outer surface of the substrate 1:

[0074] Example 1: Aluminum 40%, silicon oxide 60%.

[0075] Embodiment 2: aluminum 60%, silicon oxide 40%.

[0076] Embodiment 3: aluminum 50%, silicon oxide 50%.

[0077] The embodiment of the anti-oil stain film layer 6 film material components of the inner surface of the substrate 1:

[0078] Embodiment 1: Magnesium fluoride 60%, zirconia 40%.

[0079] Embodiment 2: Magnesium fluoride 80%, zirconium oxide 20%.

[0080] Embodiment 3: Magnesium fluoride 70%, zirconia 30%.

[0081] The embodiment of the film system of substrate 1 inner surface:

[0082] The embodiment of the anti-ultraviolet film layer 8 film material components of substrate 1 inner surface:

[0083] Example 1: 20% silicon oxide and 80% zirconium oxide.

[0084] Embodiment 2: silicon oxide 80%, zirconium oxide 20%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com