High-voltage ultra-high-speed permanent magnet synchronous motor

A permanent magnet synchronous motor, ultra-high-speed technology, applied in the direction of magnetic circuit, electric components, electrical components, etc., can solve the problems of large volume, large eddy current loss, poor motor heat dissipation effect, etc., to improve the cooling area, comprehensive cooling, improve The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

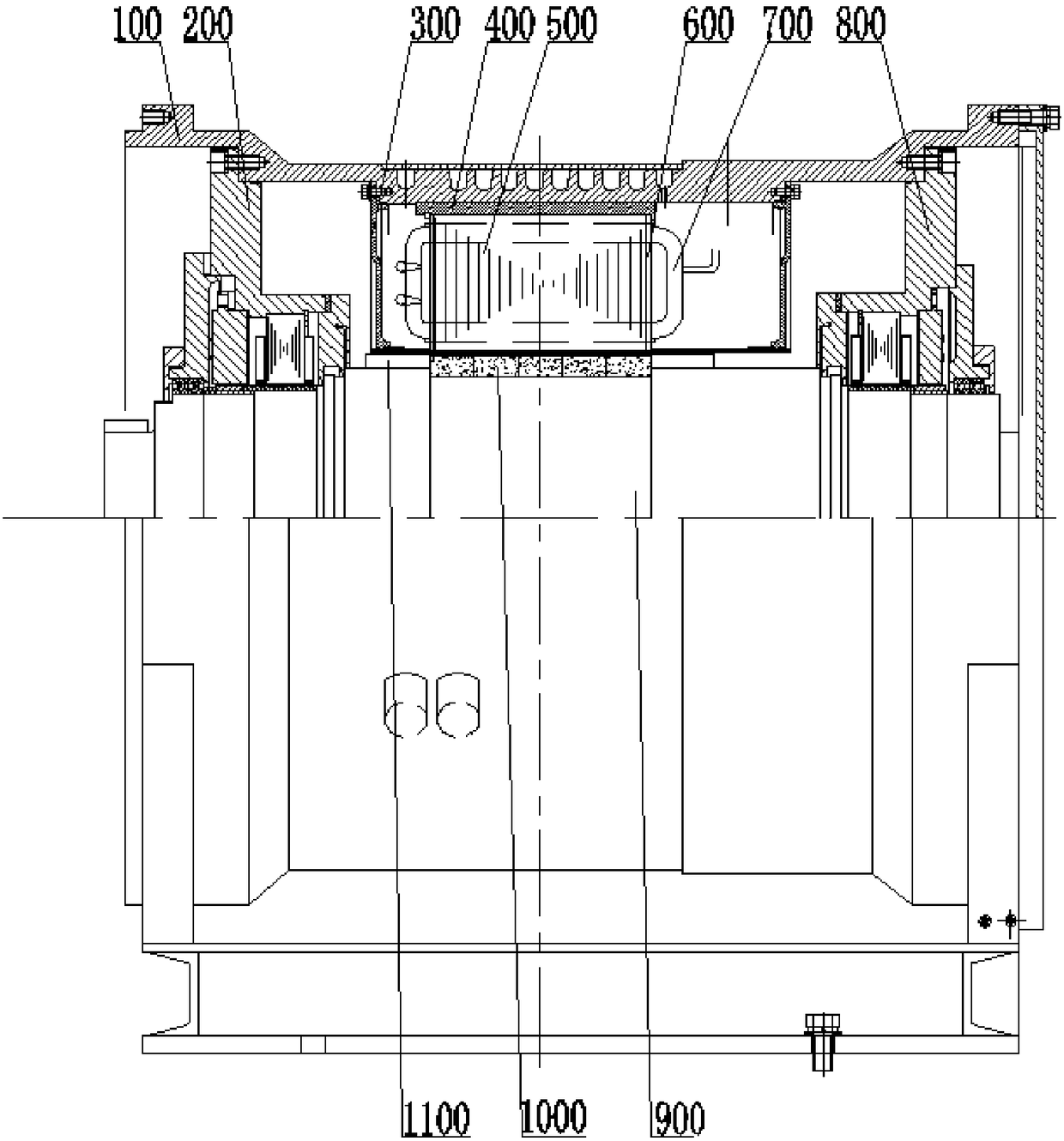

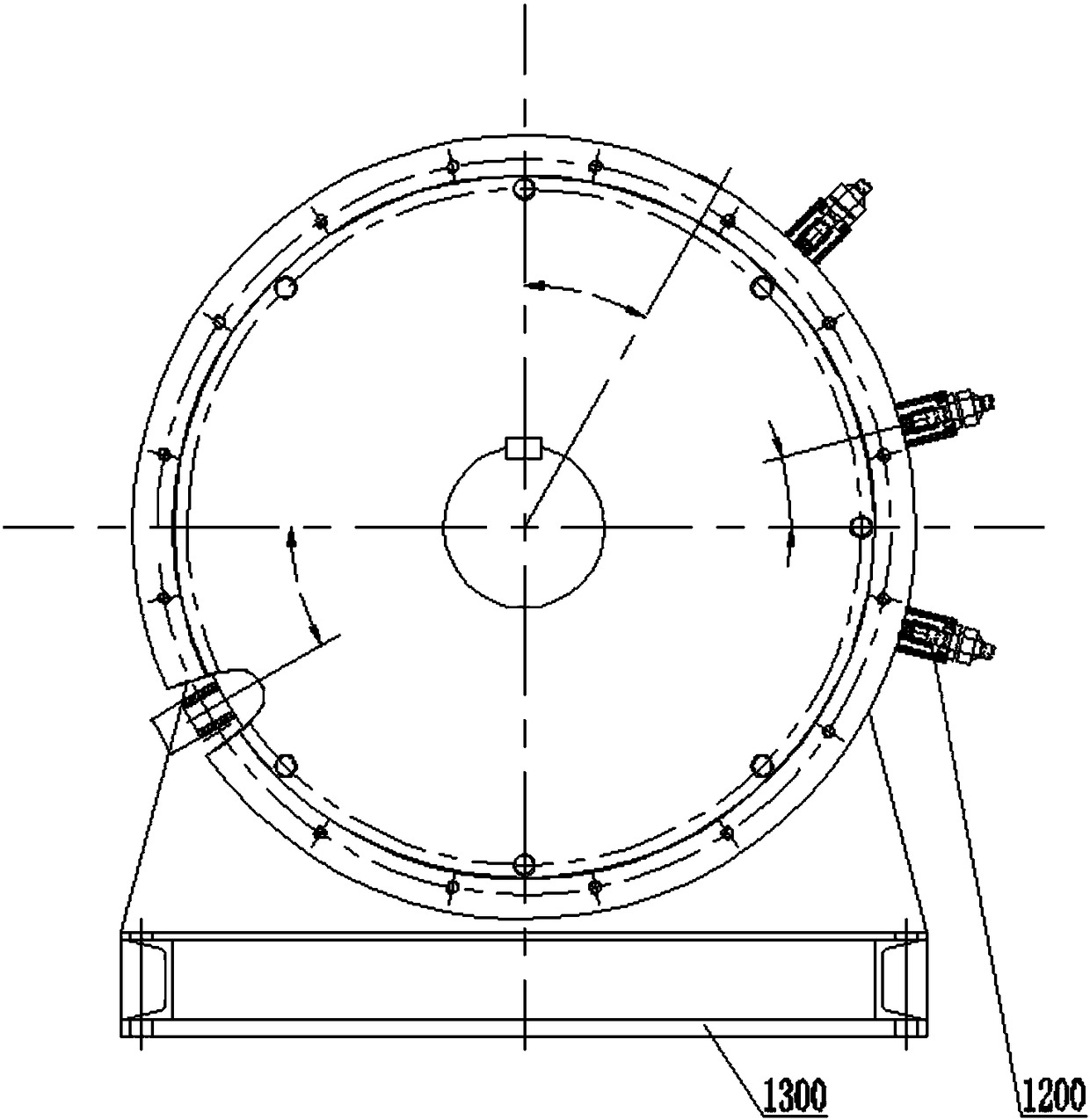

[0040] Such as Figure 1-Figure 6 As shown, the high-voltage ultra-high-speed permanent magnet synchronous motor provided in this embodiment includes: a rotor, a rotor composite protective sleeve, a stator core 500, a stator winding and a machine base 100;

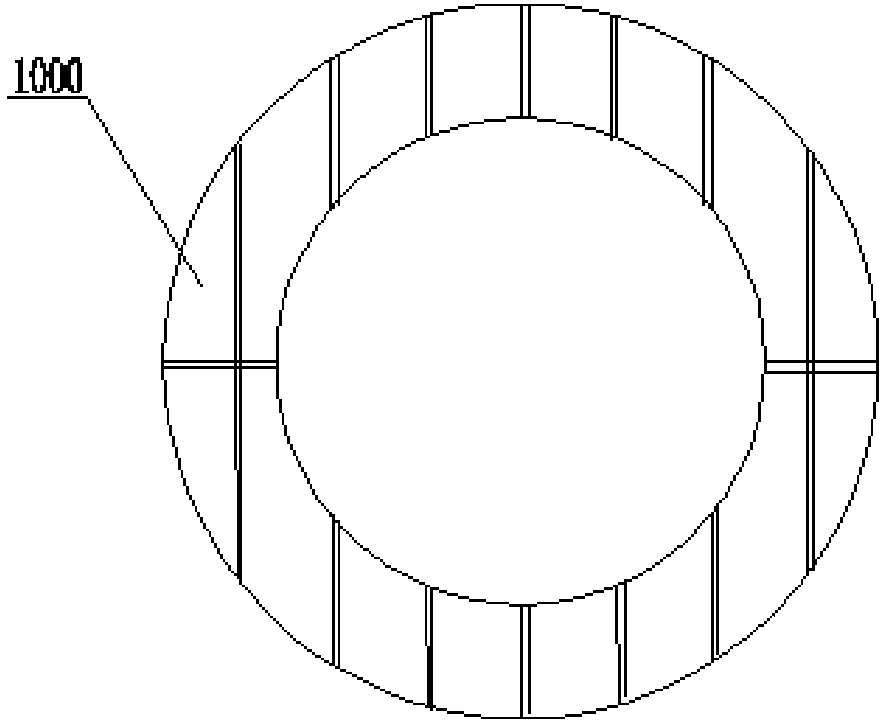

[0041] The rotor includes a rotating shaft 900 and a plurality of pairs of permanent magnets 1000, and the plurality of pairs of permanent magnets 1000 are arranged in sequence along the circumference of the rotating shaft 900, and any two adjacent permanent magnets 1000 are fixedly connected; the composite protective sleeve of the rotor includes carbon fiber layers and steel wires layer, the carbon fiber layer surrounds the rotor, and the steel wire layer surrounds the carbon fiber layer; the rotor composite protective sleeve is set outside the rotor to protect the rotor;

[0042] The stator core includes a plurality of stator punches 501, and the plurality of stator punches 501 are stacked in sequence to form a whole; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com