Method for removing persistent pollutants from surface of K424 tail nozzle part

A technology for pollutants and tail nozzles, which is applied in the field of K424 alloy parts cleaning for aero-engines, can solve the problems of complex structure of parts, inability to remove clean, and the surface state of parts cannot meet the requirements of fluorescent inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present embodiment, the specific steps of the method for removing stubborn pollutants on the surface of the K424 tail nozzle parts are as follows:

[0037] The aero-engine regulator (K424 alloy tail nozzle parts) is degreased by organic solvent→chemical degreasing→washed in hot water at (60~80)℃→washed in cold water (room temperature), in 600g / L sodium hydroxide+250g / L nitrous acid In sodium aqueous solution, soak at 140°C for 2 hours, take it out → wash with hot water at (60-80)°C → wash with cold water (room temperature) → rinse with high-pressure water (0.4-0.6) MPa (repeatedly rinse), use pH test paper to check the residue on the surface of the part The pH value of the water (pH ≤ 8), and finally the parts are dried by compressed air, and the pollutants on the surface of the parts can be completely removed by naked eyes.

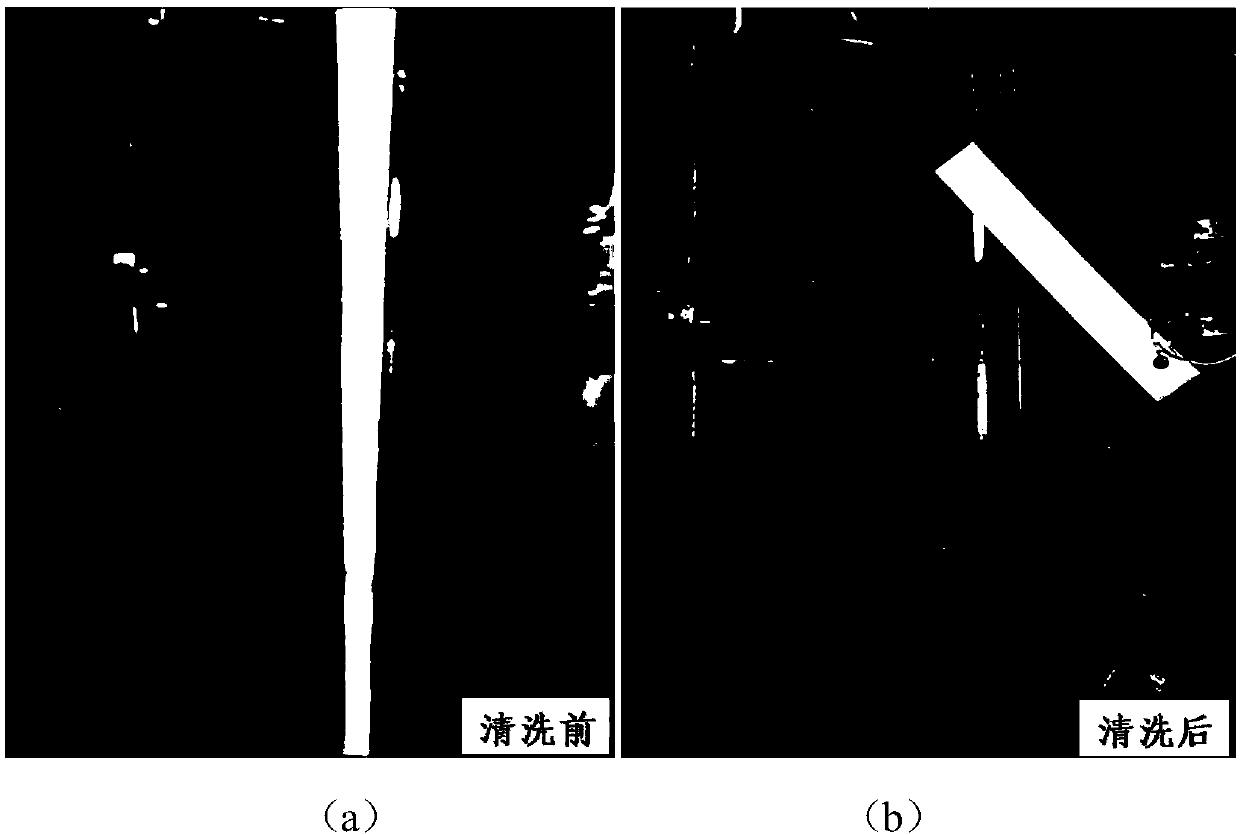

[0038] Such as figure 1 As shown, from the comparison before and after the removal of pollutants on the surface of K424 alloy parts, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com